Method for preparing anhydrous monosodium citrate

A technology of anhydrous citric acid and citric acid, applied in the preparation of carboxylate, organic chemistry, etc., can solve the problems of lack of solution to moisture absorption, lack of granulation and detection means, insufficient dispersibility and performance, etc.

Inactive Publication Date: 2012-01-11

NINGXIANG XINYANG CHEM

View PDF3 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In addition, there are serious deficiencies in the dispersibility and performance of these traditional plastic additives

The existing method for preparing sodium citric acid adopts the neutralization reaction of citric acid and sodium carbonate, and prepares monosodium citrate containing water through processes such as crystallization and drying. The sodium citric acid prepared by this method contains water of crystallization, and the crystal particles are too large to be To meet the requirements of plastic foaming agents, the particle size of anhydrous sodium citrate used in plastic foaming is required to be 10-15 μm, and the particle size is required to be fine and uniform, and there is a lack of corresponding granulation and detection methods. It has strong hygroscopicity in the natural environment. For special applications with strict water content requirements, there is no means to solve the problem of moisture absorption in the process of granulation, packaging, storage and transportation of the product.

There is no preparation of anhydrous citric acid-sodium as plastic additive method at present

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment

[0029]

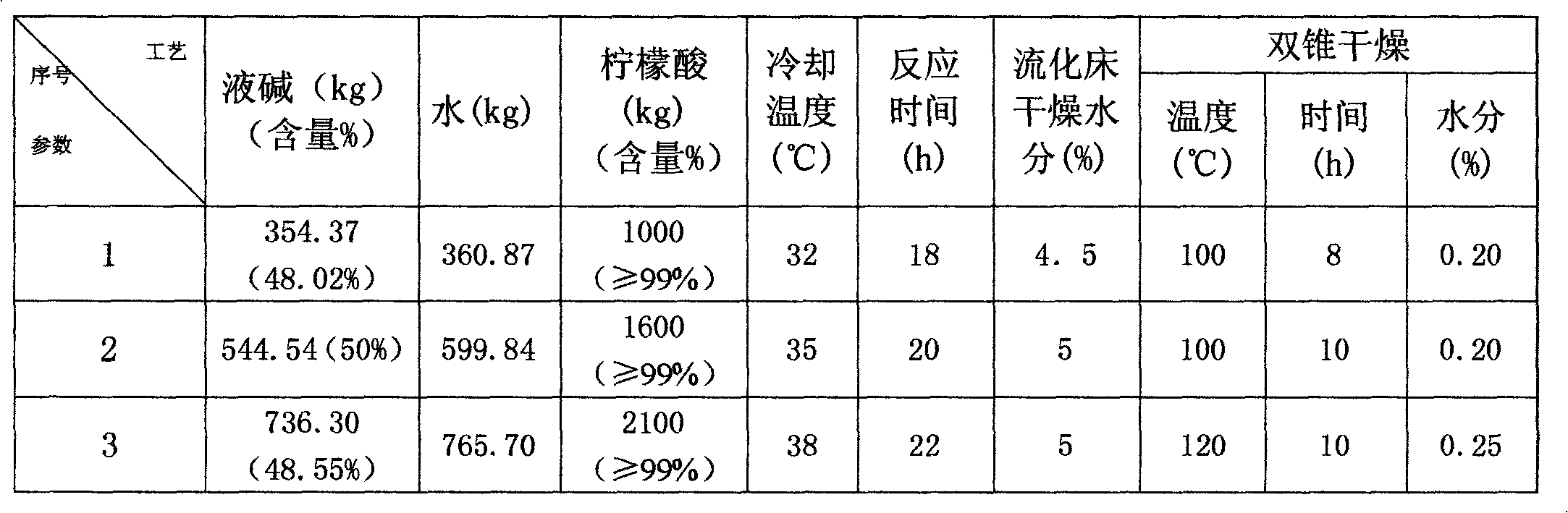

[0030] As can be seen according to the above table examples, the anhydrous monosodium citrate prepared by the method of the present invention meets the requirements of plastic blowing agents. The production process is easy to control and stable.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

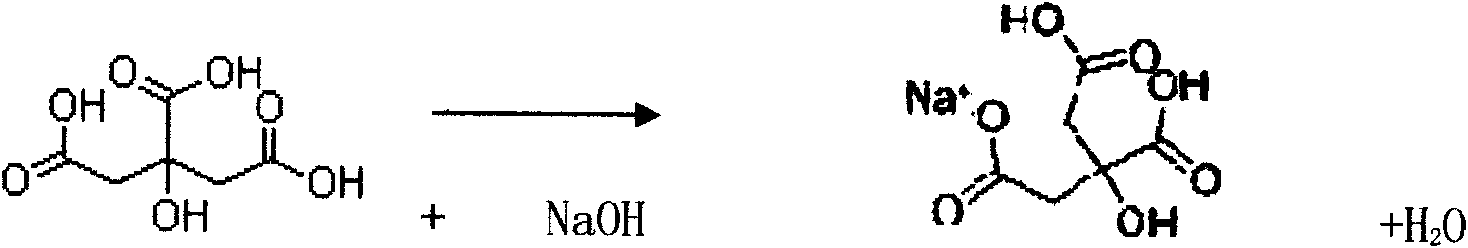

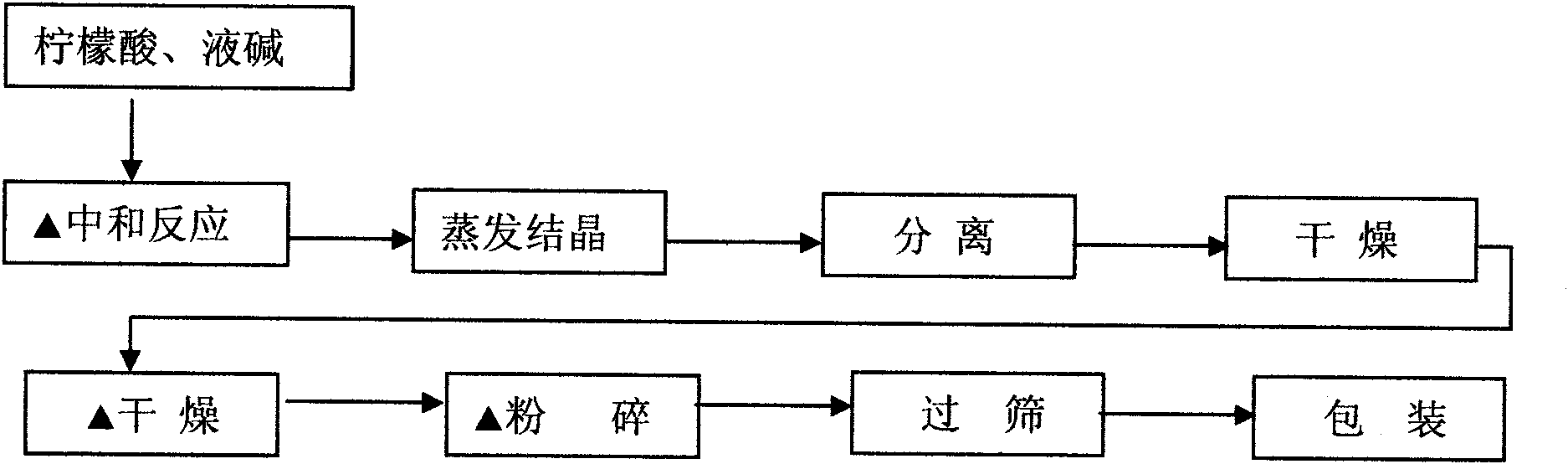

The invention relates to a method for preparing a chemical product, in particular to a method for preparing anhydrous monosodium citrate, serving as a novel high-efficiency, environmentally-friendly and multifunctional plastic auxiliary agent. In the method, citric acid and caustic soda liquid are used as raw materials; monosodium citrate is prepared by using acid-base neutralization reaction; the requirement that drying decrement is less than 0.3 percent can be met by performing secondary drying for 8-10 hours by using a vacuum rotary drum at the temperature of 90-120 DEG C; then the requirement that the average grain diameter is 10-15mum can be met through crushing and sieving of a crusher; by adopting the method, the uniformity degree and the fineness degree of foams can be improved, and the number of the foams in a unit area of a product is increased, so that the dispersibility of a foaming agent is improved, a foam structure is stabilized, and the decomposition temperature and the decomposition rate of the foaming agent are adjusted. The method has the beneficial effects of providing an environmentally-friendly and nontoxic plastic product while enhancing the function of the conventional auxiliary agent.

Description

technical field [0001] The invention relates to a preparation method of chemical products, in particular to a preparation method of a novel high-efficiency, environment-friendly and multifunctional plastic additive anhydrous monosodium citrate. Background technique [0002] At present, the traditional plastic foaming aids include ethanolamine, ammonia water, urea diethylguanidine, lead oxide, etc. Foaming aids have a wide range of applications, large production and sales, and many modified varieties. The production process emits a large amount of highly polluting Organic nitrogen and ammonia nitrogen wastewater, also discharge acid mist, strong acid water, etc. In addition, there are serious deficiencies in the dispersibility and performance of these traditional plastic additives. The existing method for preparing sodium citric acid adopts the neutralization reaction of citric acid and sodium carbonate, and prepares monosodium citrate containing water through processes such...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07C59/265C07C51/41C08J9/06

Inventor 石志勇

Owner NINGXIANG XINYANG CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com