Heat-conducting high density polyethylene composite material and preparation method as well as application thereof

A technology of high-density polyethylene and composite materials, which is applied in the field of engineering plastics, can solve problems such as the reduction of mechanical properties of composite materials and limit the application of thermally conductive composite materials, and achieve the effects of low cost, high thermal conductivity and mechanical properties, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

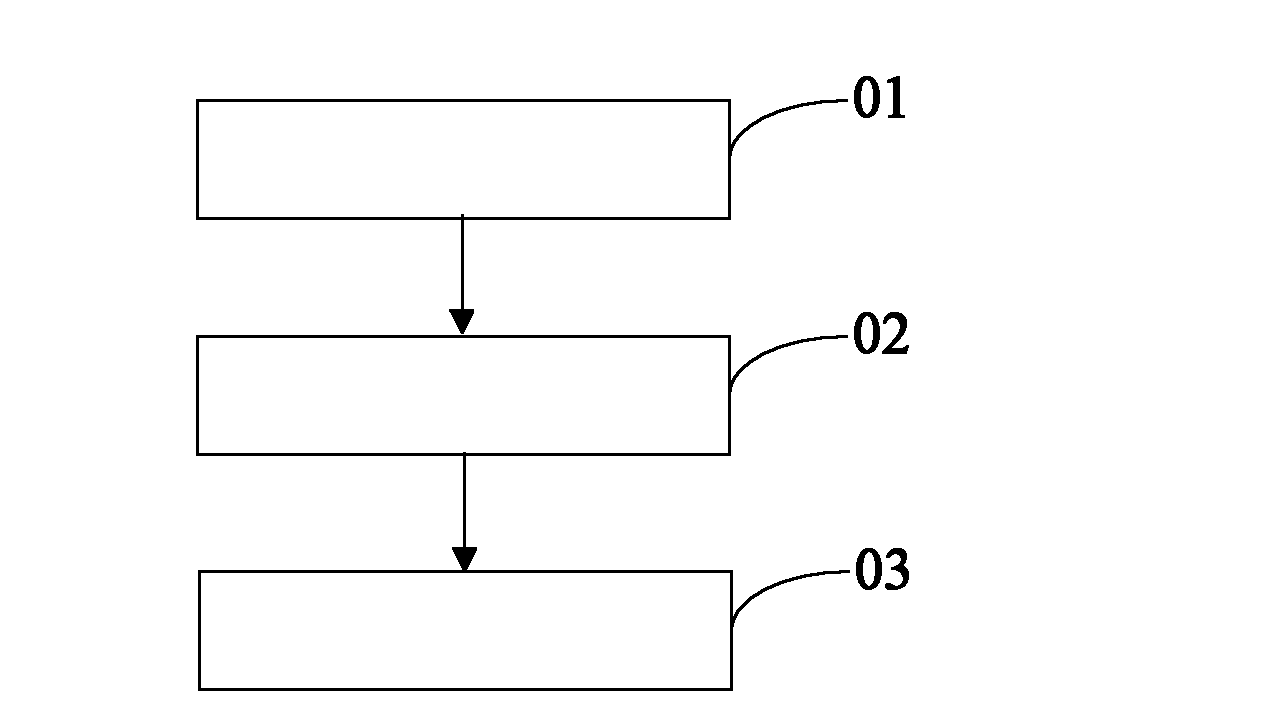

[0024] see figure 1 , figure 1 Show the flow chart of the method for preparing a thermally conductive high-density polyethylene composite material according to an embodiment of the present invention, including the following steps:

[0025] In step S01, an active thermally conductive filler is prepared

[0026] Mix the inorganic heat-conducting agent and the coupling agent according to the mass ratio of 95-98%: 2-5%, and stir for 5-10 minutes at a temperature of 90-110°C to obtain the active heat-conducting filler;

[0027] S02, mixed

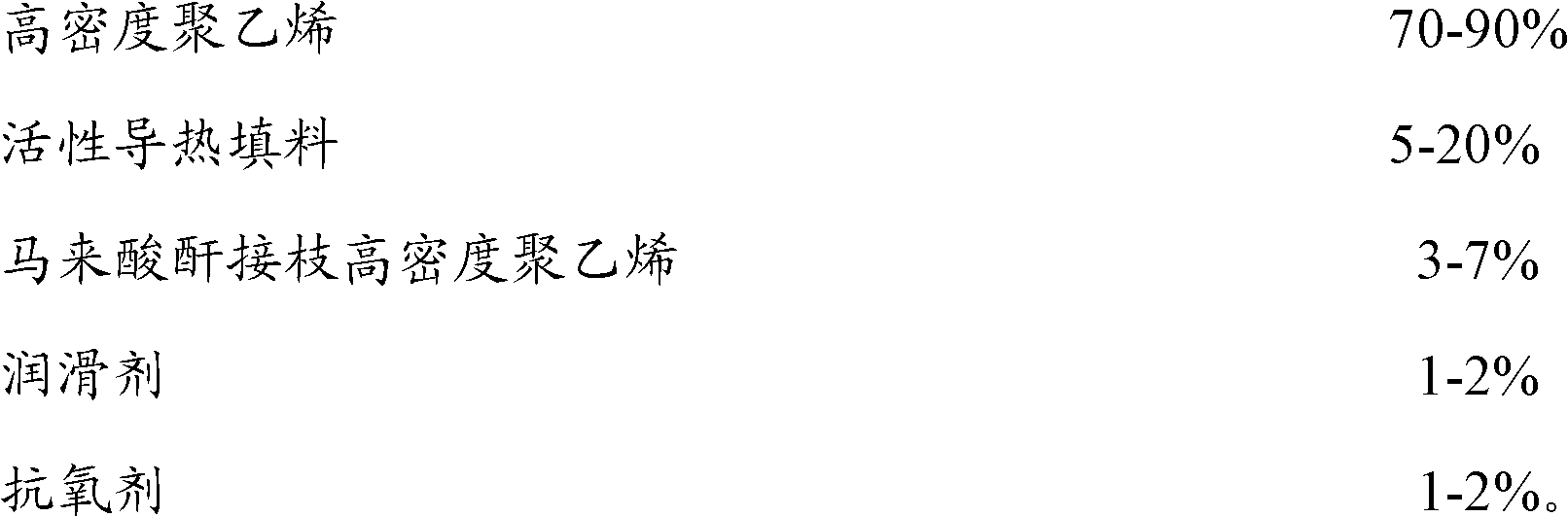

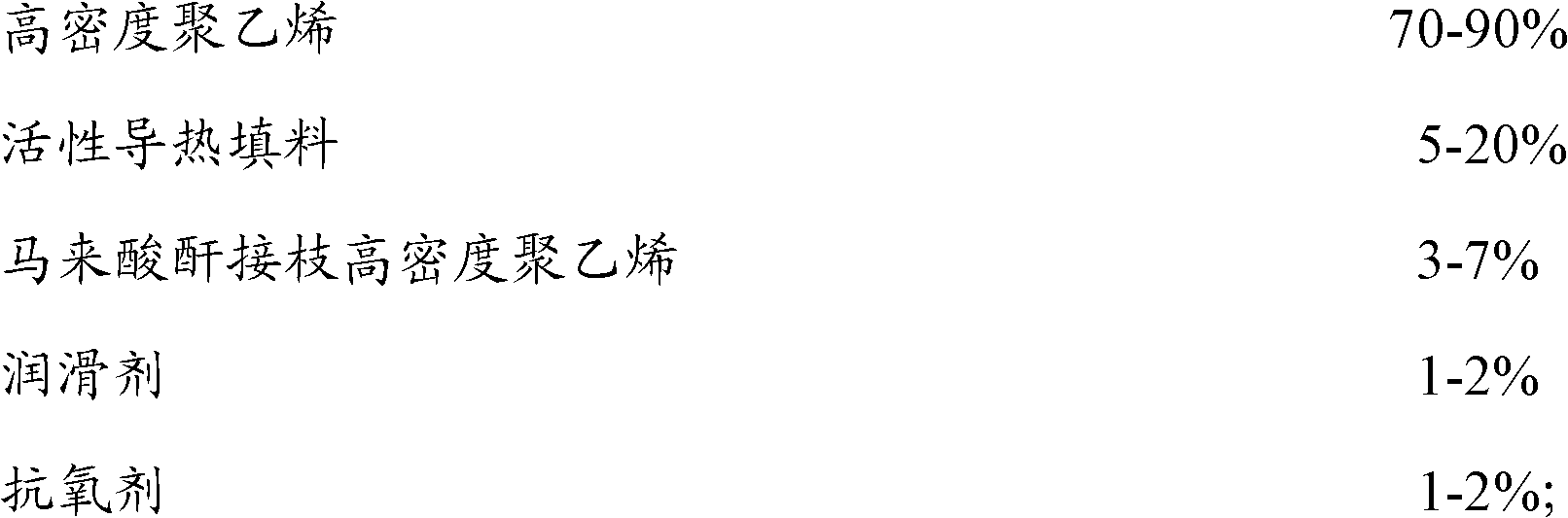

[0028] Mix the following components in mass percentage to obtain a mixture;

[0029]

[0030] S03, extrusion processing

[0031] The mixture is extruded at a temperature of 150-180° C. to obtain a thermally conductive high-density polyethylene composite material.

[0032] Specifically, the heat-conducting high-density polyethylene, lubricant, antioxidant, inorganic heat-conducting agent and coupling agent are the same as those described ...

Embodiment 1

[0046] The preparation method of the high-density polyethylene composite material of the embodiment of the present invention comprises the following steps:

[0047] 90% by mass of HDPE, 5% by mass of active thermally conductive filler, 3% by mass of maleic anhydride grafted high-density polyethylene, 1% by mass of lubricating agent, the mass percent content is 1% antioxidant and mixes uniformly in the high-speed mixer, and wherein this maleic anhydride grafted high-density polyethylene is self-made maleic anhydride grafted high-density polyethylene;

[0048] Put the mixed material into the hopper of the twin-screw extruder, melt and blend, extrude and granulate to obtain a high-density polyethylene composite material, wherein the temperature settings of each zone of the screw are: Zone 1 temperature: 120-130 ℃; Zone 2 temperature: 130~140℃; Zone 3 temperature: 140~150℃; Zone 4 temperature: 140~170℃; Zone 5 temperature: 140~170℃; Zone 6 temperature: 140~170℃; : 140~170℃; eight...

Embodiment 2

[0050] The preparation method of the high-density polyethylene composite material of the embodiment of the present invention comprises the following steps:

[0051] 82% by mass of HDPE, 10% by mass of active thermally conductive filler, 5% by mass of maleic anhydride grafted high-density polyethylene, 1.5% by mass of lubricating agent, a mass percent content of 1.5% antioxidant is mixed uniformly in a high-speed mixer, wherein the maleic anhydride grafted high-density polyethylene is a self-made maleic anhydride grafted high-density polyethylene;

[0052] The mixed materials are put into the hopper of the twin-screw extruder, melted and blended, extruded and granulated into alloy materials. Among them, the temperature setting of each zone of the screw is as follows: first zone temperature: 120-130°C; second zone temperature: 130-140°C; third zone temperature: 140-150°C; fourth zone temperature: 140-170°C; fifth zone temperature: 140 ~170°C; Six-zone temperature: 140-170°C; Se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com