White antialkali sealing priming paint and its preparation method

A sealing primer, white technology, applied in the direction of coating, etc., can solve the problems of no appearance improvement on the wall surface, poor alkali resistance, etc., to improve the background of wall decoration, improve brushing performance, reduce dosage and quality Requirements and effects of painting and grading difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

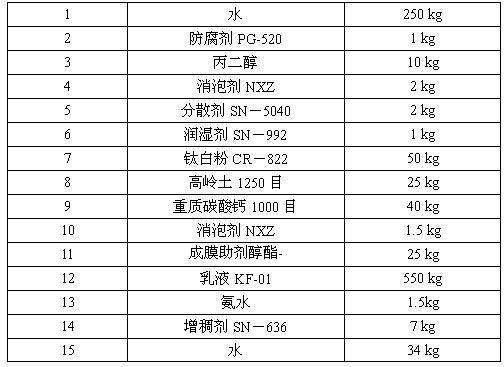

[0019] Table 1 Raw materials and ratio

[0020]

[0021] The implementation process is:

[0022] (1) Use a paint mixing tank and a disperser, and add items 1-6 according to the amount at a speed of about 200 rpm. After adding items 1-6, increase the speed to 400-500 rpm and keep it for about 20 minutes until the additives are evenly dispersed.

[0023] (2) While stirring at 400 rpm, slowly add items 7-9 according to the amount. After items 7-9 are added, increase the speed to 1000-1200 rpm and keep for 20-30 minutes until the fineness is less than 45 microns.

[0024] (3) Continue to add items 10-12 at 200-300 rpm, and then adjust the pH value to 9 with ammonia water. Then dilute the SN-636 thickener 3 times with water, and then add it slowly to adjust the viscosity to 85-90KU. Supplement the remaining water to add up to 1000kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com