Method of preparing Baohuoside I from epimedium

A technology of baohuoside and epimedium, which is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems of inability to carry out industrial production, low content, and difficulty in direct separation and purification, and avoid precipitation Effects of loss, increase in solubility, and increase in yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

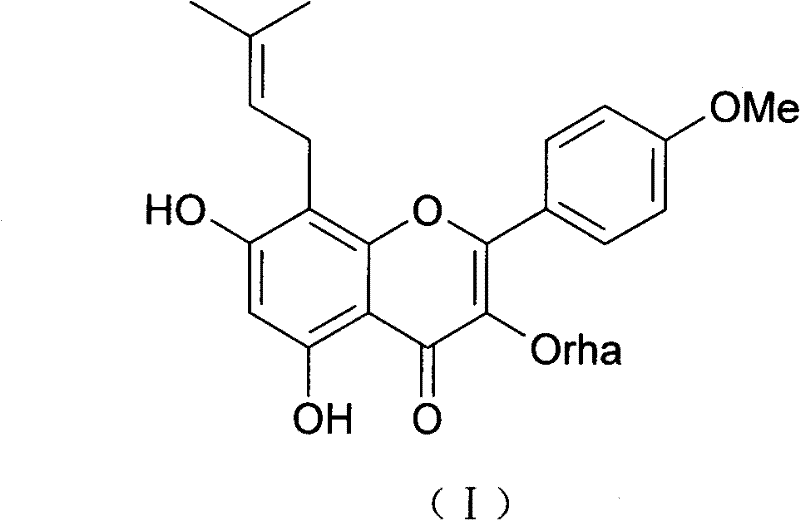

Image

Examples

Embodiment 1

[0022] Get 1 kg of Epimedium medicinal material, and the content of baohuoside I determined by HPLC is 0.08%, add water and decoct 2 times, each time for 1 hour, add water 20 kg each time, the extract is concentrated in vacuum until the specific gravity is 1.05 (60°C), Add 5g of Tween 80 and 5g of cellulase, stir and enzymolyze at 50°C for 24 hours, and determine that the enzymolysis solution contains 4.1g of baohuoside I.

[0023] The two macroporous resins D101 and AB-8 are uniformly mixed according to the mass ratio of 1:1, and then loaded into the column. One-third of the enzymolysis solution obtained by enzymolysis is passed through the macroporous resin column at a certain flow rate, and washed with water first. Then use 30%, 60%, and 95% ethanol to carry out gradient elution in sequence, collect the 60% ethanol eluate, recover the ethanol, and dry, that is, 2.0 g of the crude product of Baohuoside I is obtained, and the content of Baohuoside I is 52%; Heat and dissolve ...

Embodiment 2

[0027] Take 1 kg of Epimedium medicinal material, determine the content of baohuoside I by high performance liquid chromatography to be 0.08%, add 50% ethanol for reflux extraction twice, each time for 1 hour, add 10 kg of 50% ethanol each time, recover ethanol from the extract, and concentrate in vacuo When the specific gravity was 1.05 (60°C), 5g Tween 80 and 5g cellulase were added, stirred at 50°C for 24 hours, and the enzymolysis solution contained 5.3g of baohuoside I.

[0028] The two macroporous resins D101 and AB-8 are uniformly mixed at a mass ratio of 1:1 and packed into a column. The enzymolysis liquid obtained by enzymolysis is passed through the macroporous resin column at a certain flow rate, washed with water, and then sequentially washed with 30% , 60%, 95% ethanol to carry out gradient elution, collect 60% ethanol eluate, reclaim ethanol, dry, promptly get Baohuoside I crude product 8.2g, Baohuoside I content is 54%; Baohuoside I The crude product was dissolv...

Embodiment 3

[0030] Take 1 kg of Epimedium medicinal material, determine the content of baohuoside I by HPLC to be 0.08%, add 50% ethanol for reflux extraction twice, each time for 1 hour, add 10 kg of 50% ethanol each time, reclaim ethanol from the extract, and adjust the pH to 5.0, add 5g Tween 80 and 5g cellulase, stir and enzymolyze at 50°C for 24 hours, and determine that the enzymolysis solution contains 5.2g of baohuoside I.

[0031] The two macroporous resins D101 and AB-8 are uniformly mixed according to the mass ratio of 1:2 and then loaded into the column. The enzymolysis solution obtained by enzymolysis passes through the macroporous resin column at a certain flow rate, first washed with water, and then sequentially washed with 30% , 60%, 95% ethanol to carry out gradient elution, collect 60% ethanol eluate, reclaim ethanol, dry, promptly get Baohuoside I crude product 7.1g, Baohuoside I content is 52%; Baohuoside I The crude product was dissolved by heating with absolute ethan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com