Steel for mandrel pipe mill mandril and preparation technology thereof

A preparation process and movement technology, used in metal rolling, manufacturing tools, metal rolling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Present embodiment has produced a kind of steel, and its concrete composition is as follows:

[0029] C 0.30%, Si 0.35%,

[0030] Mn 1.0%, Cr 3.2%,

[0031] Mo 0.5%, V 0.35%,

[0032] Nb 0.04% P < 0.015%,

[0033] S <0.015%, O ≤30ppm

[0034] Fe balance

[0035] Specific steps are as follows:

[0036] A. Melting: After the alloy is designed according to the above components, it is smelted in an electric furnace, and the batch materials in the above formula are placed in the electric furnace, smelted at a temperature above 1500°C, and the φ450mm electrode rod is cast;

[0037] B. Electroslag remelting: After electroslag remelting, the content of gas and inclusions can be reduced, and steel ingots with uniform composition, compact structure and high quality can be obtained. The capping voltage is 58V, and the filling ratio is 0.8;

[0038] C. Annealing: heat at 700°C for 8 hours and then cool with the furnace;

PUM

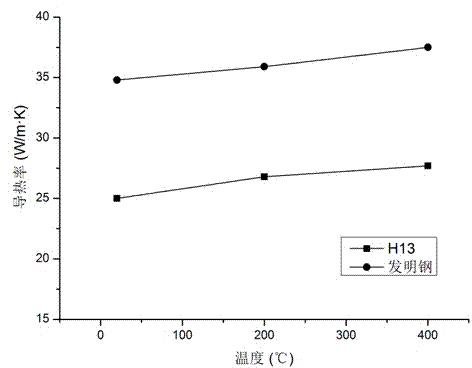

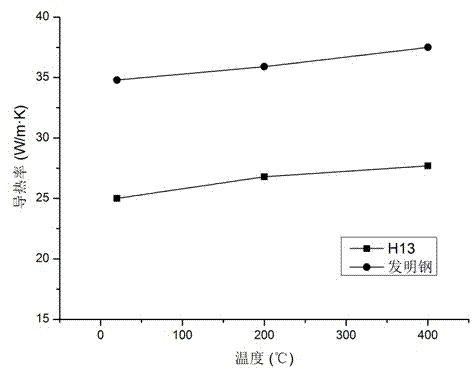

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com