Method for casting crystal by seed crystal induction

A seed crystal and crystal technology, applied in the field of polycrystalline and single crystal semiconductor materials, to achieve the effects of low cost, high photoelectric efficiency and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

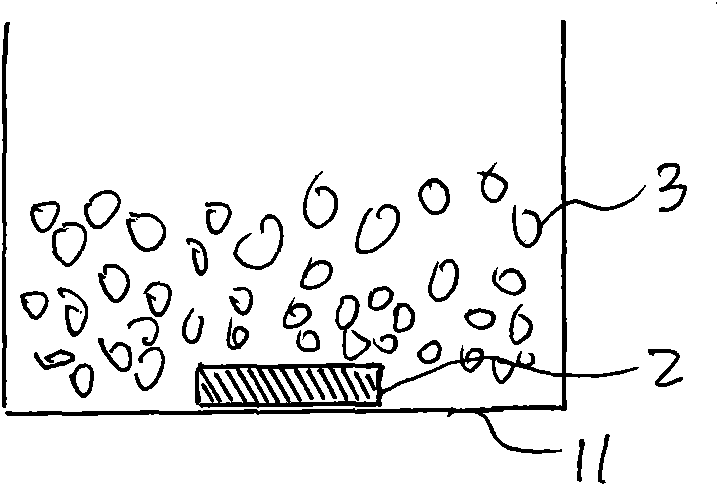

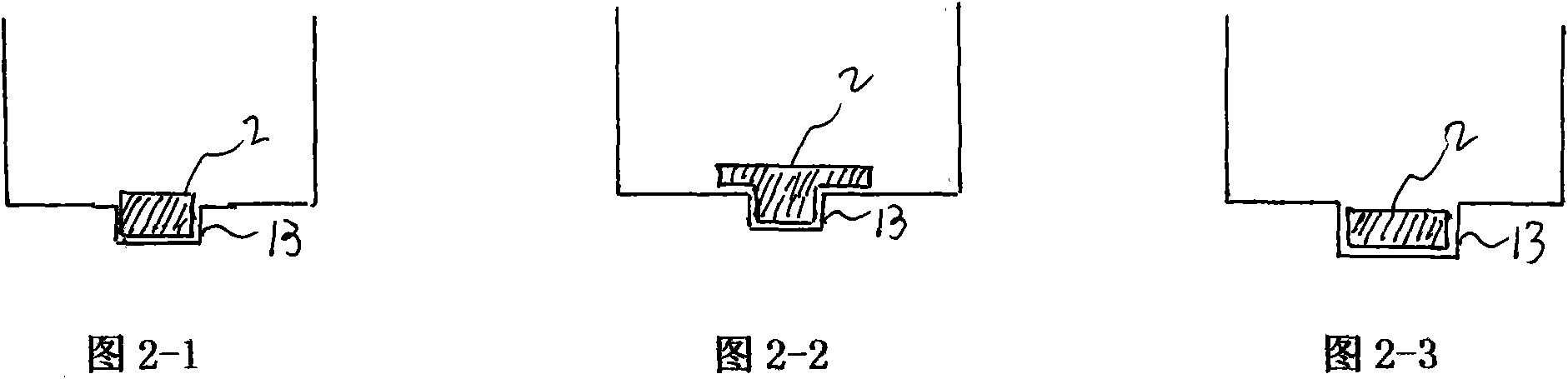

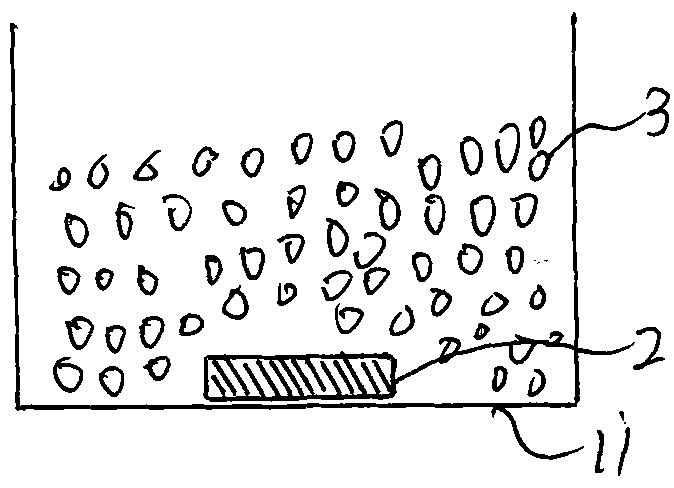

[0046] figure 1 In the method of the present invention of the silicon crystal manufacturing device using the silicon crystal growth process of the VGF method, the seed crystal is arranged at the bottom of the crucible. Wherein, the single crystal seed crystal plate 2 covers part of the inner surface of the bottom 11 of the crucible. The silicon raw material 3 is filled and covered above the seed crystal plate and other spaces in the crucible. The figure shows that the silicon raw material at the bottom of the crucible close to the seed crystal is preferably a small-sized granular or massive raw material. In this embodiment, the seed crystal plate can be fixed on the bottom of the crucible by, for example, welding or placing it directly.

[0047] To implement the method of the present invention, the heater is first activated to form a longitudinal temperature gradient in the crucible. Among them, the temperature near the horizontal plane at the lowest part of the crucible under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com