Medium-low-temperature baked titanium-porcelain composite metal plate for building decoration purpose and manufacture process thereof

A technology of architectural decoration and composite metal, applied in the direction of construction, building components, building structure, etc., can solve the problem of aggravating raw material and energy waste and environmental pollution, poor weather resistance, corrosion resistance, rust resistance, and volatile matter volatilization. Large and other problems, to achieve the effect of good overall decoration effect, beautiful appearance and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

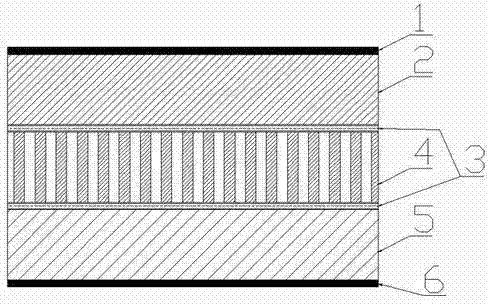

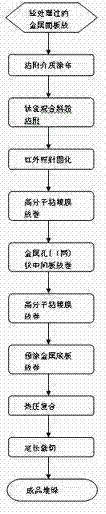

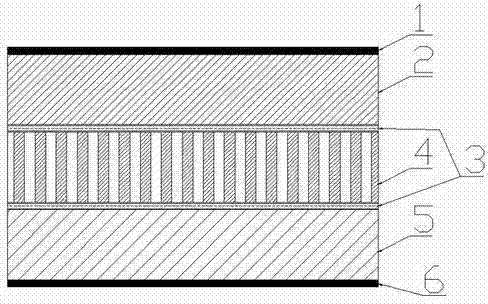

[0009] Such as figure 1 Shown: a medium-low temperature baked titanium-ceramic composite metal plate for architectural decoration, which is composed of a titanium-ceramic dense protective layer 1, a metal panel 2, a polymer adhesive film 3, a metal hole (network)-shaped intermediate plate 4, It consists of a metal base plate 5 and a pre-coated resin protection layer 6 . On the metal base plate 5, the resin protective layer 6 is pre-coated earlier to form a pre-coated metal base plate, and then adopt such as figure 2 The process flow shown is continuous mass production, and its production process is: metal panel 2 unwinding → attaching medium coating on metal panel 2 → attaching titanium porcelain mixed powder to form a uniform layer on metal panel 2 Film → cured by medium and low temperature ultra-short wave infrared radiation at 230°C~260°C, and finally forms a dense protective layer of titanium porcelain on the metal panel 2 1 → polymer adhesive film 3 unwinding → metal ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com