Lithium ion battery pole piece coil vacuum drying oven

A lithium-ion battery and vacuum drying oven technology, which is applied to battery electrodes, dry solid materials, local agitation dryers, etc., can solve problems such as transpiration upward movement, low equipment resource efficiency, and long equipment occupation time, so as to avoid drying Effects of uneven quality, improvement of equipment usage efficiency, and reduction of equipment occupation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific implementation plan

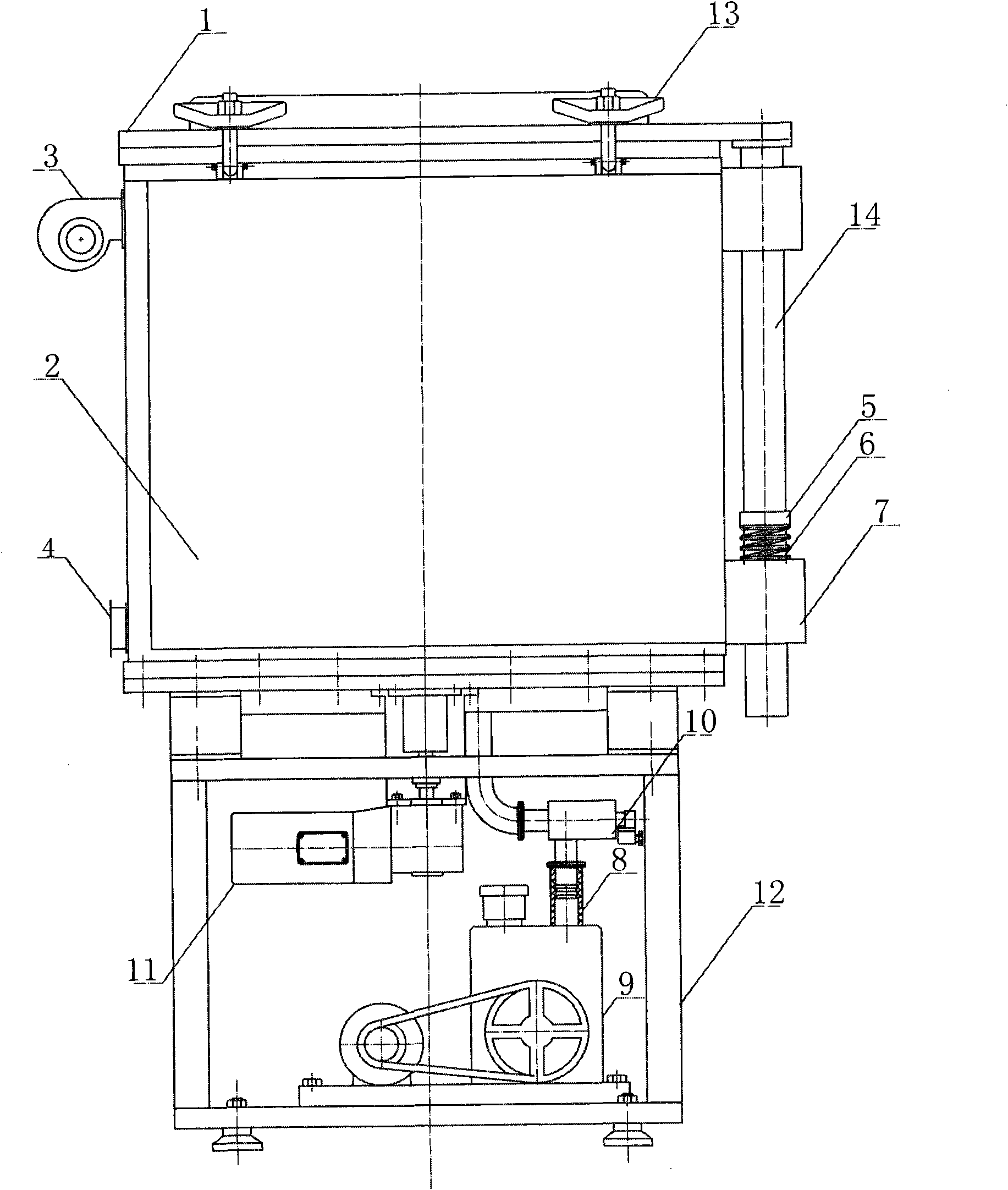

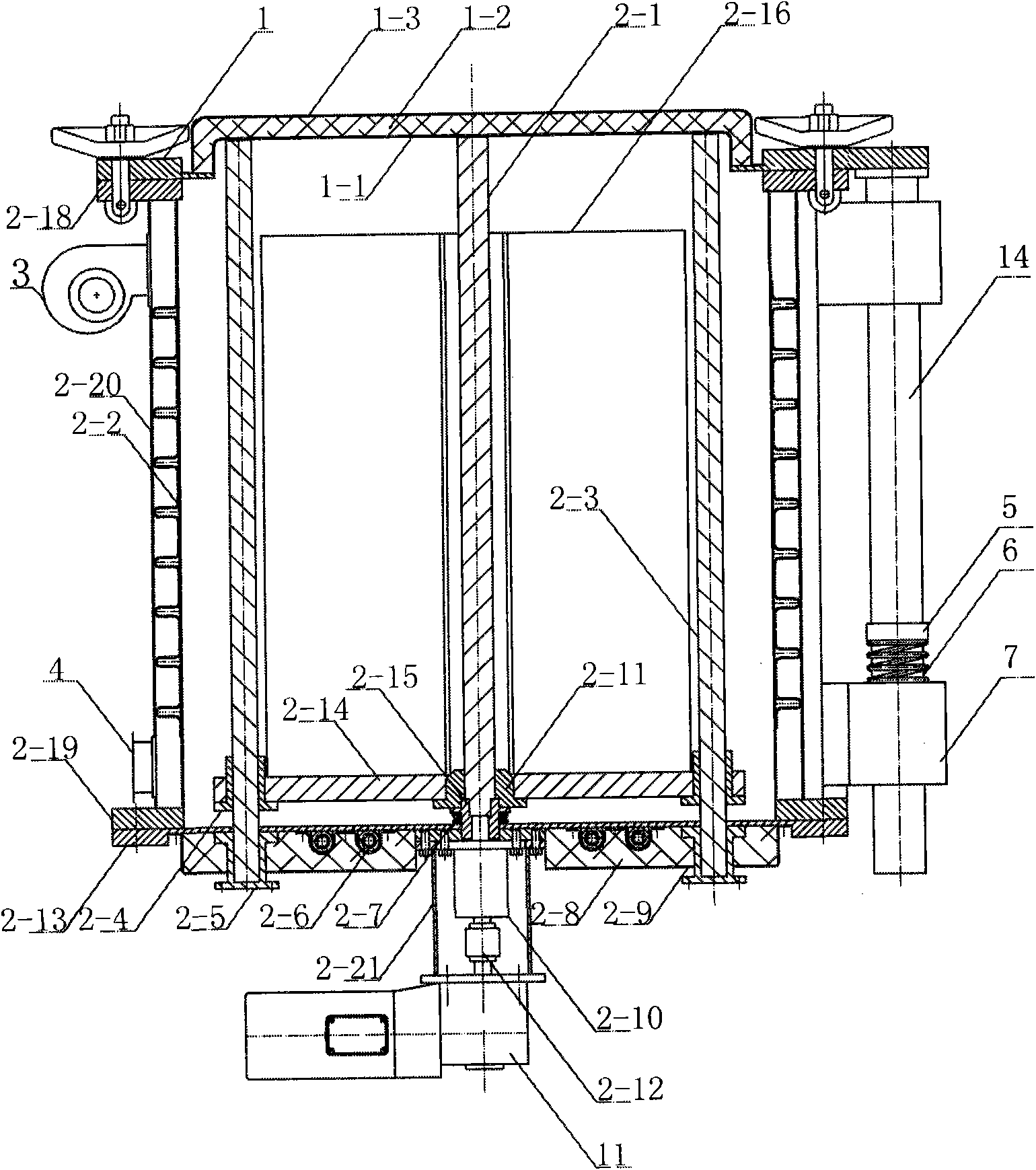

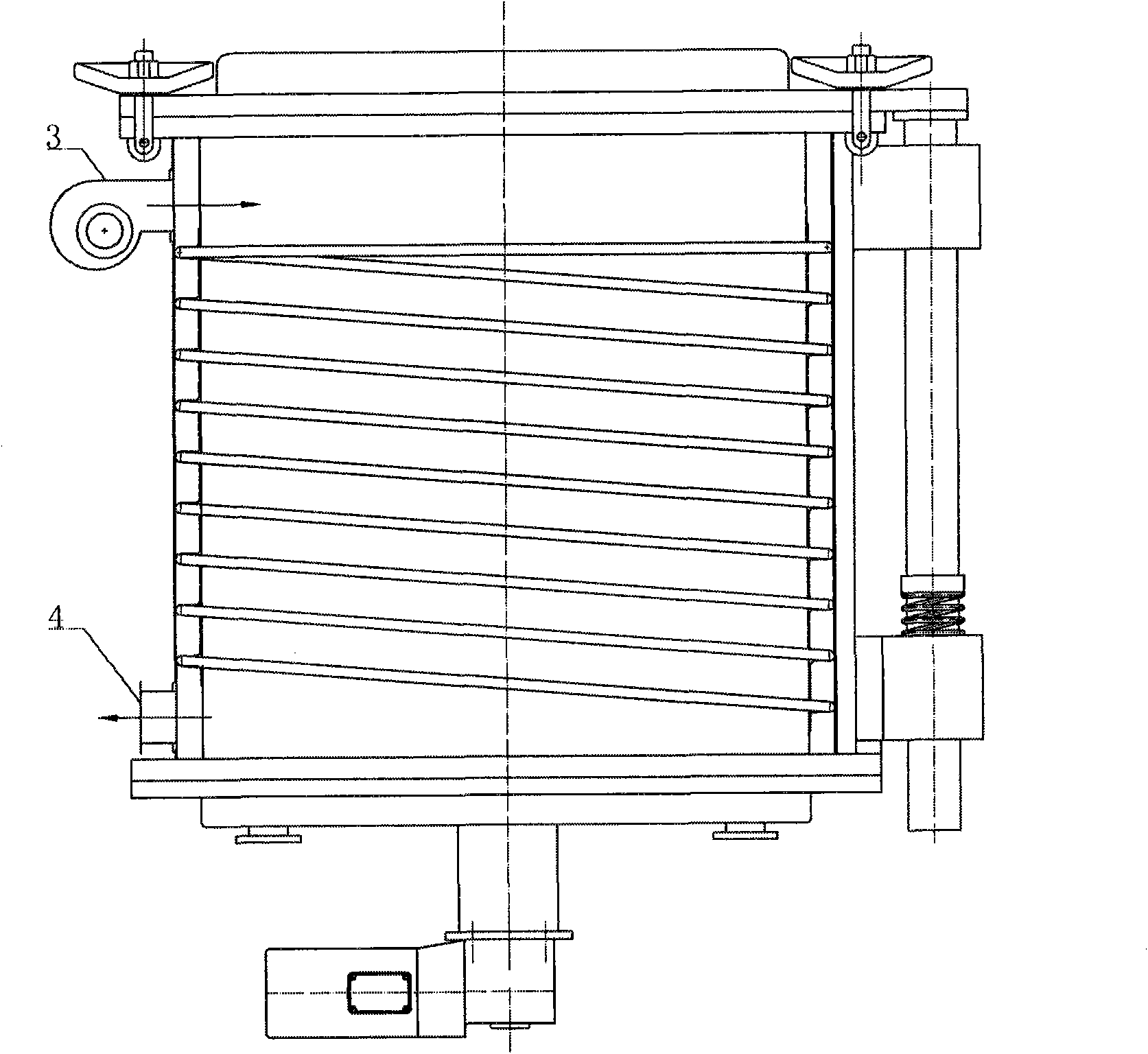

[0023] Reference figure 1 , Spiral annular flow passage jacketed box 2 is axially fixed above the frame 12, the box cover 1 and the upper end of the lifting shaft 14 are connected and fixed in the radial direction of the spiral annular flow passage jacketed box 2, the middle section of the lifting shaft 14 Below the retaining ring 5 is a column spring 6. The sliding unit 7 is installed at both ends of the lifting shaft 14. The top of the lifting shaft 14 fixes the box cover flange 1, and the suction port of the vacuum pump 9 is connected to the vacuum battery valve 10 through a vacuum hose 8. Connected to the spiral ring-shaped rib vacuum chamber 2-2, the geared motor 11 is installed at the bottom of the spiral ring-shaped channel jacketed box 2 to combine figure 2 , Geared motor 11 is connected to mechanical seal 2-10 through coupling 2-12, fixed by geared motor base 2-21, mechanical seal 2-10 is connected to connecting sleeve 2-15, connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com