Mg-Al-Y-based hydrogen storage material and preparation method thereof

A hydrogen storage material, mg-al-y technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., to reduce the dehydrogenation temperature, improve the kinetic performance of hydrogen absorption and desorption, and simplify the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

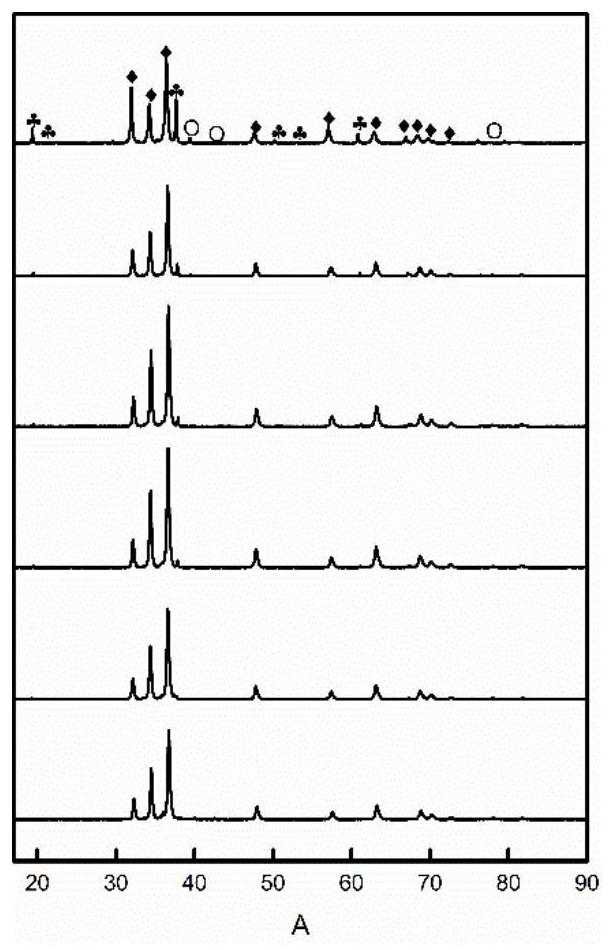

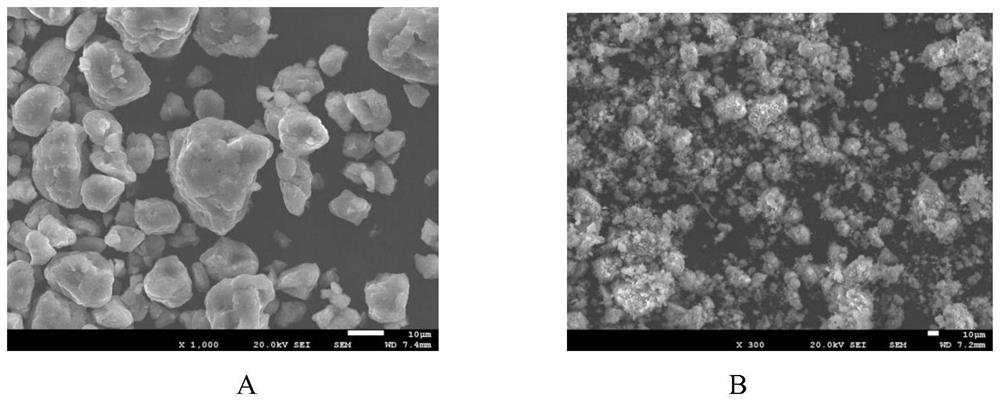

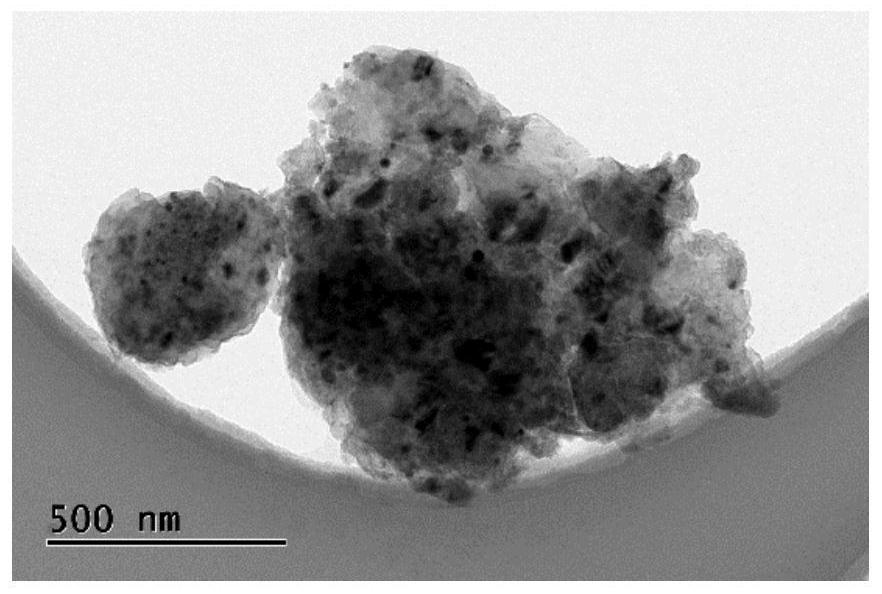

Image

Examples

preparation example Construction

[0037] A preparation method of Mg-Al-Y based hydrogen storage material, comprising the following steps:

[0038] (1) Prepare the as-cast Mg-Al-Y alloy by vacuum induction melting method;

[0039] (2) crushing the obtained ingot alloy to obtain alloy powder;

[0040] (3) Carry out mechanical grinding to the obtained alloy powder;

[0041] (4) Add the pre-prepared porous carbon-based catalyst Tm@C (Tm=Fe, Cu, Co, etc.) and fluoride (AF d =NiF 2 ,CrF 3 ,ZrF 4 etc.), continue grinding for several hours;

[0042] (5) Activate the hydrogen storage material obtained above, and then conduct a hydrogen absorption and desorption performance test.

[0043] The prepared alloy of step (1) is Mg x al y Y z , wherein, x+y+z=100, 70≤x≤90, 5≤y≤15, 5≤z≤10; the product obtained in step (3) is Mg with nanocrystalline structure x al y Y z Alloy, the product of step (4) gained is Mg x al y Y z +awt.%Tm@C (Tm=Fe, Cu, Co, etc.)+bwt.%AF d (AF d =NiF 2 ,CrF 3 ,ZrF 4 etc.) nanocrysta...

Embodiment 1

[0053] Taking the preparation of 1000g sample as an example, put 830.11g Mg (99.99%), 160.66g Y (99.9%) and 48.76g Al (99.99%) into the vacuum induction melting furnace. Place metal magnesium around and place rare earth in the middle high-temperature area, cover the furnace cover and evacuate to a vacuum degree below 0.05Pa, at the same time heat with a power of 0.2KW, keep it for 10 minutes, and then evacuate to a vacuum degree below 0.05Pa , and then pass in an inert gas of 0.06MPa as a protective gas, the protective gas is pure helium or a mixed gas of helium + argon, and the volume ratio of the mixed gas is about 1:1. The heating power at the beginning of smelting is gradually adjusted from 0.2KW to 1kW, and the temperature is controlled at about 800-850°C to melt the magnesium metal. Then the heating power is increased to 15kW, and the temperature is controlled at about 1500-1520°C to melt all the metals. After keeping under the melting condition for 3-5 minutes, medium-f...

Embodiment 2

[0056] Taking the preparation of a 1000g sample as an example, put 830.11g Mg (99.99%), 160.66g Y (99.9%) and 48.76Al (99.99%) into a vacuum induction melting furnace at a melting temperature of 1500°C and protect it under a He atmosphere. The volatilization of Mg was suppressed, the ingot was obtained and crushed, and passed through a 300-mesh sieve to obtain a powder sample. Put the powder sample into the ball mill tank, mill for 10-15 hours, the ratio of ball to material is 35:1, the speed of the ball mill is 300-350rpm, the tank needs to be filled with Ar before the ball mill treatment, to avoid excessive oxidation of the alloy powder, and the ball mill is over Then add 5wt.% Fe@C and 5wt.% CrF to it 3 , repeat the above steps, ball mill for 2±1h.

[0057] For the Mg obtained above 90 al 5 Y 5 +5wt.%5wt.%Fe@C+5wt.%CrF 3 Carry out activation treatment, the condition is 320-360 ℃, hydrogen absorption under the hydrogen pressure of 3-3.5Mpa, release hydrogen at 300-360 ℃...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com