Processing method and application of starch raw material

A technology of starchy raw materials and processing methods, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of low enzymatic hydrolysis liquefaction liquid, affecting the production efficiency of sugar liquid, and the decrease of filtration speed, etc., to achieve The effect of reducing waste water discharge, reducing energy and equipment consumption, and reducing stratification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

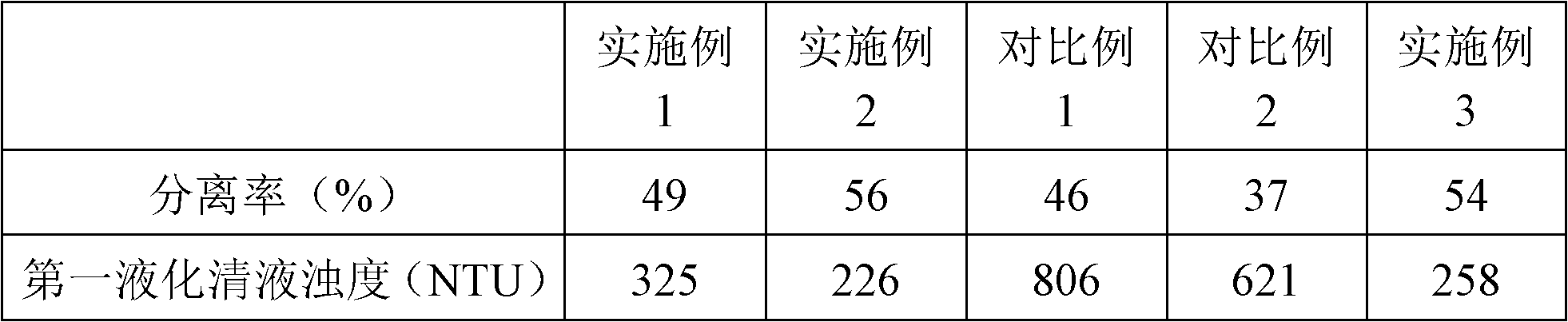

Examples

Embodiment 1

[0048] 100 parts by weight of corn were pulverized to obtain a pulverized product with an average particle diameter of 400 μm, and the pulverized product was mixed with 400 parts by weight of water at 45° C. to obtain a starch slurry.

[0049] At 50°C, the starch slurry was mixed with the α-amylase of 6.4 enzyme activity units / g corn flour for 60 minutes to obtain a mixture, which was sprayed into contact with steam at 156°C in an injector (steam and mixture The weight ratio is 0.05:1), the contact time is 5 seconds, so that the temperature of the mixture after contacting with the steam is 95°C, and the laminar flow is maintained for 120 minutes to obtain a primary liquefied liquid.

[0050] The above-mentioned primary liquefied liquid is again sprayed and contacted with steam at 156°C in the injector (the weight ratio of steam to mixture is 0.05:1), and the contact time is 1 second, so that the temperature of the mixture after contacting with steam again is 135°C. ℃, and keep...

Embodiment 2

[0055] 100 parts by weight of corn were pulverized to obtain a pulverized product with an average particle diameter of 400 μm, and the pulverized product was mixed with 180 parts by weight of water at 60° C. to obtain a starch slurry.

[0056] At 50°C, the starch slurry was mixed with the α-amylase of 24 enzyme activity units / g corn flour for 100 minutes to obtain a mixture, which was sprayed into contact with steam at 160°C in an injector (steam and mixture The weight ratio is 0.1:1), the contact time is 1 second, so that the temperature of the mixture after contacting with the steam is 100° C., and the laminar flow is maintained for 180 minutes to obtain a primary liquefied liquid.

[0057] The above-mentioned primary liquefied liquid is again sprayed and contacted with steam at 160°C in the injector (the weight ratio of steam to mixture is 0.1:1), and the contact time is 3 seconds, so that the temperature of the mixture after contacting with steam again is 140 ℃, and keep a...

Embodiment 3

[0075] 100 parts by weight of corn were pulverized to obtain a pulverized product with an average particle diameter of 400 μm, and the pulverized product was mixed with 300 parts by weight of water at 50° C. to obtain a starch slurry.

[0076] At 50°C, the starch slurry was mixed with the α-amylase of 20 enzyme activity units / g corn flour for 150 minutes to obtain a mixture, which was sprayed into contact with steam at 160°C in an injector (steam and mixture The weight ratio is 0.08:1), the contact time is 3 seconds, so that the temperature of the mixture after contacting with steam is 97° C., and the laminar flow is maintained for 150 minutes to obtain a primary liquefied liquid.

[0077] The above-mentioned primary liquefied liquid is again sprayed and contacted with steam at 160°C in the injector (the weight ratio of steam to mixture is 0.08:1), and the contact time is 2 seconds, so that the temperature of the mixture after contacting with steam again is 138 ℃, and keep at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com