Extruded high-tin bronze alloy and preparation method thereof

A technology of extruding and forming high-tin bronze, which is applied in the field of tin-bronze alloys, can solve problems such as difficulty in meeting actual product requirements, hard tin-bronze alloys, and easy cracks, and achieve good market application prospects, reduce lead segregation, reduce The effect of the crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

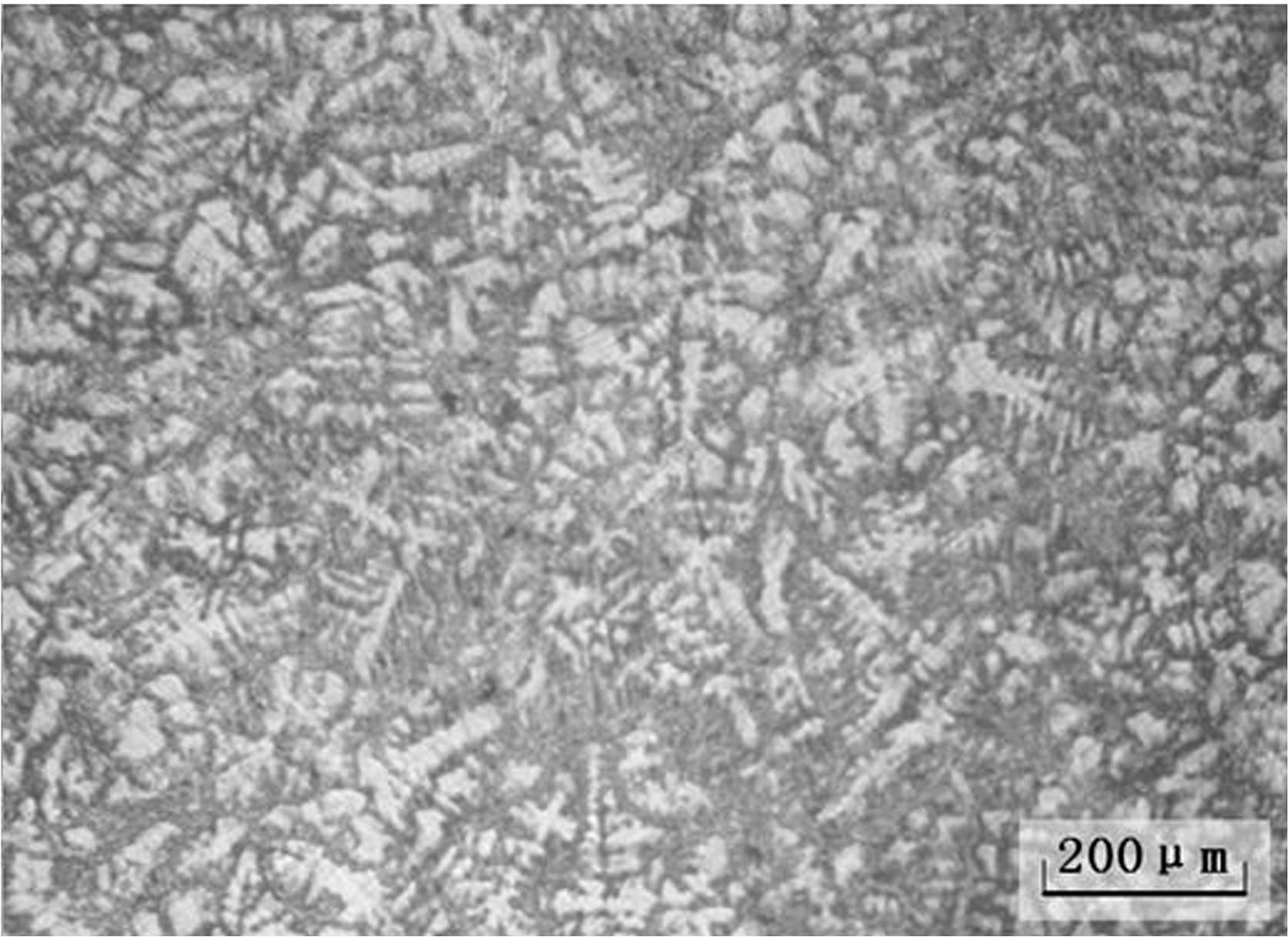

Embodiment 1

[0024] The extruded high-tin bronze alloy of this embodiment is composed of the following components in weight percentage: Sn 12%, Pb 1%, Ni 2%, impurity components Fe, Sb, Al, Zn, P, Si and Bi The total content of is 0.28%, and the balance is Cu.

[0025] The preparation method of the extruded high-tin bronze alloy of the present embodiment, the specific steps are:

[0026] (1) Prepare raw materials: take 1# electrolytic copper plate with a purity of 99.95%, 1# tin ingot with a purity of 99.90%, 1# nickel plate with a purity of 99.99%, 1# lead ingot with a purity of 99.994%, and then cut , drying and surface degreasing treatment, ready for use;

[0027] (2) Ingredients: Weigh the raw materials processed in step (1) according to the composition of the extruded high-tin bronze alloy;

[0028] (3) Melting: First add charcoal about 20cm thick into the melting furnace, then add electrolytic copper plates into the melting furnace, heat rapidly to melt the electrolytic copper plat...

Embodiment 2

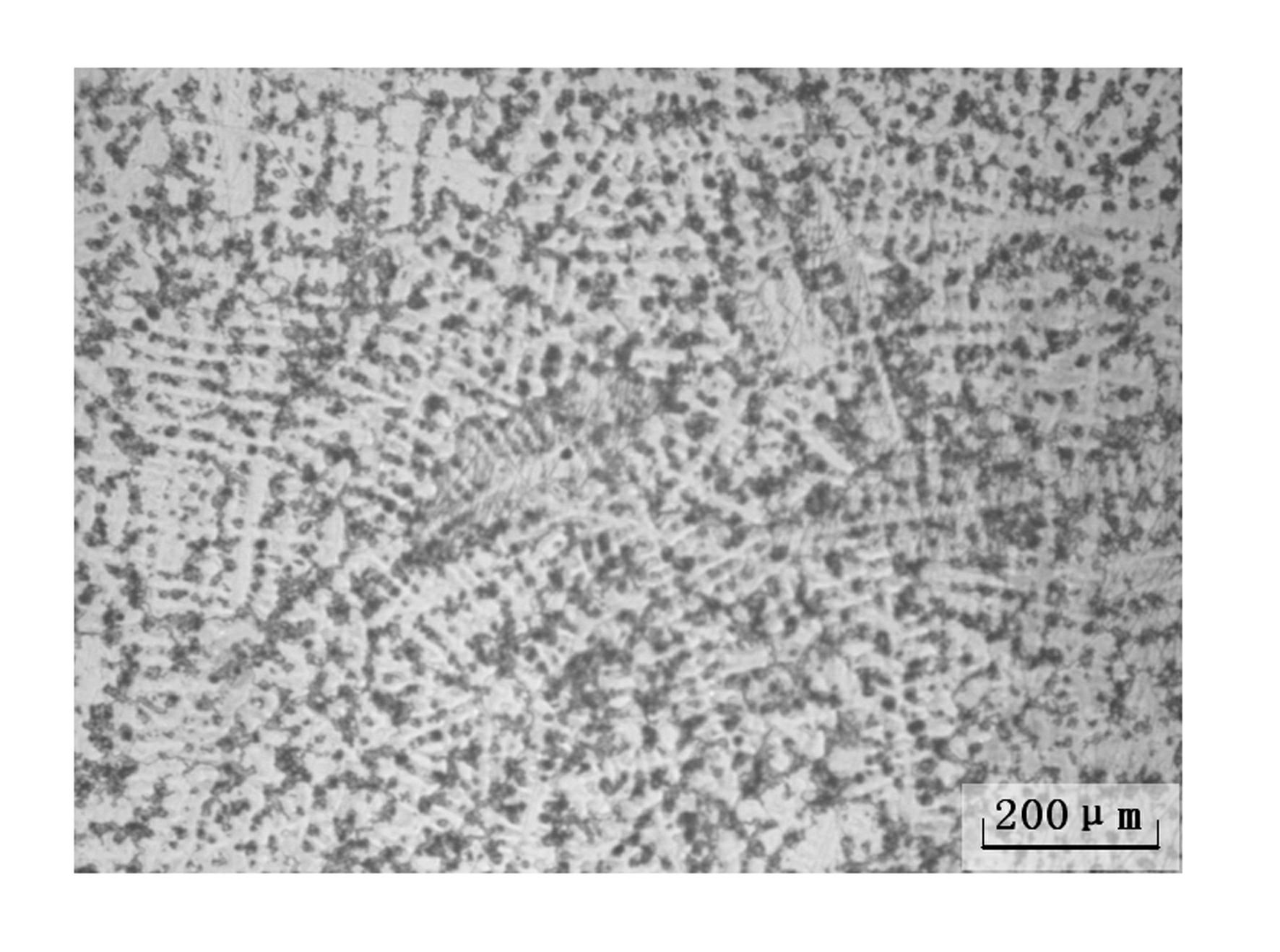

[0035]The extruded high-tin bronze alloy of this embodiment is composed of the following components in weight percentage: Sn 10%, Pb 2.5%, Ni 3.5%, impurity components Fe, Sb, Al, Zn, P, Si and Bi The total content of is 0.25%, and the balance is Cu.

[0036] The preparation method of the extruded high-tin bronze alloy of the present embodiment, the specific steps are:

[0037] (1) Prepare raw materials: take 1# electrolytic copper plate with a purity of 99.95%, 1# tin ingot with a purity of 99.90%, 1# nickel plate with a purity of 99.99%, 1# lead ingot with a purity of 99.994%, and then cut , drying and surface degreasing treatment, ready for use;

[0038] (2) Ingredients: Weigh the raw materials processed in step (1) according to the composition of the extruded high-tin bronze alloy;

[0039] (3) Melting: First add charcoal about 20cm thick into the melting furnace, then add electrolytic copper plates into the melting furnace, heat rapidly to melt the electrolytic copper p...

Embodiment 3

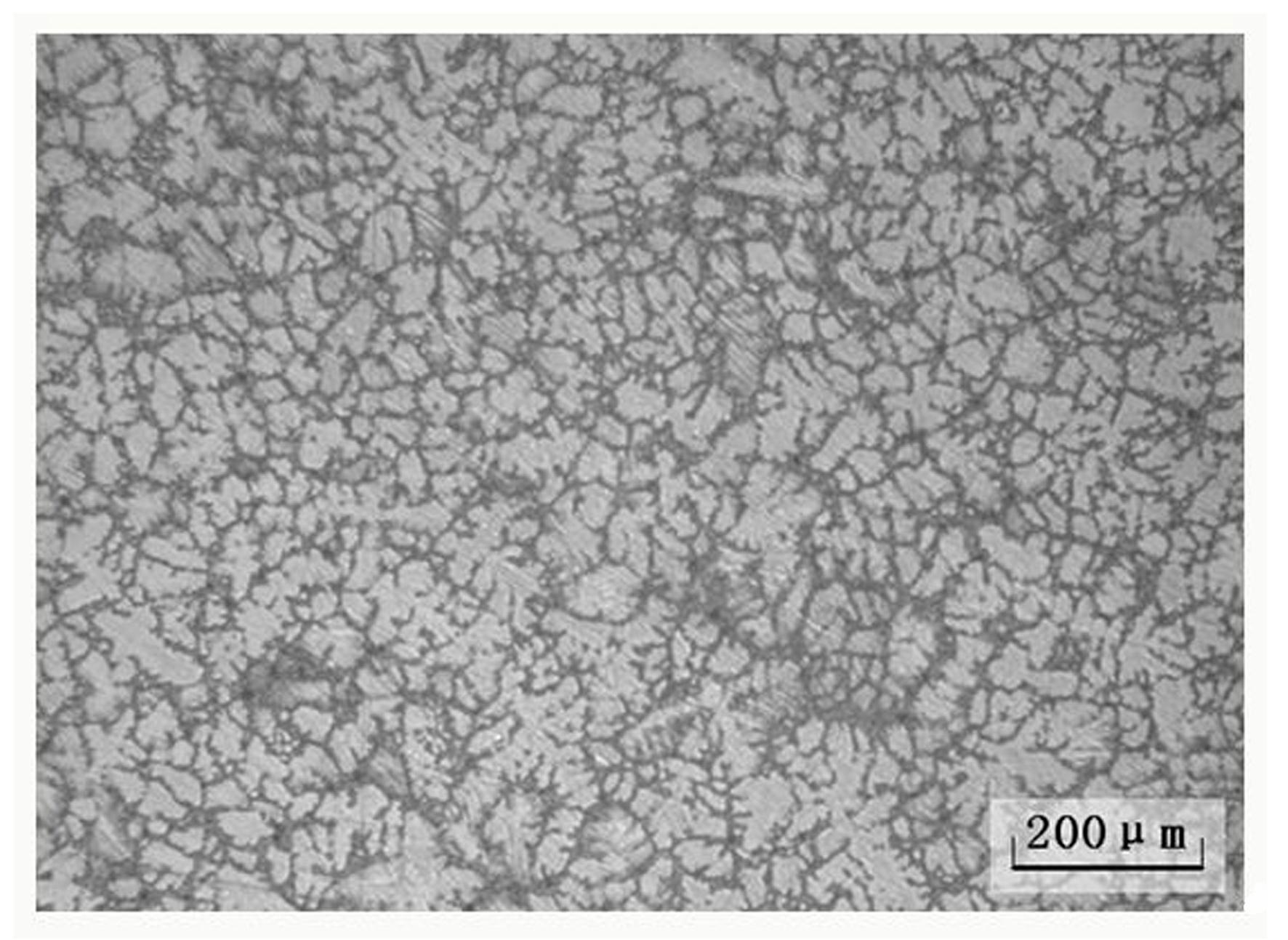

[0045] The extruded high-tin bronze alloy of this embodiment is composed of the following components in weight percentage: Sn 8%, Pb 4%, Ni 5%, impurity components Fe, Sb, Al, Zn, P, Si and Bi The total content of is 0.23%, and the balance is Cu.

[0046] The preparation method of the extruded high-tin bronze alloy of the present embodiment, the specific steps are:

[0047] (1) Prepare raw materials: take 1# electrolytic copper plate with a purity of 99.95%, 1# tin ingot with a purity of 99.90%, 1# nickel plate with a purity of 99.99%, 1# lead ingot with a purity of 99.994%, and then cut , drying and surface degreasing treatment, ready for use;

[0048] (2) Ingredients: Weigh the raw materials processed in step (1) according to the composition of the extruded high-tin bronze alloy;

[0049] (3) Melting: First add charcoal about 20cm thick into the melting furnace, then add electrolytic copper plates into the melting furnace, heat rapidly to melt the electrolytic copper plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com