Manufacturing method of silicon nitride heating plate

A technology for a silicon nitride heating sheet and a manufacturing method, applied in the field of electrothermal materials, can solve the problems of not too high thermal conductivity, not too wide temperature difference range, etc., and achieve the effects of high thermal shock performance, high qualification rate and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

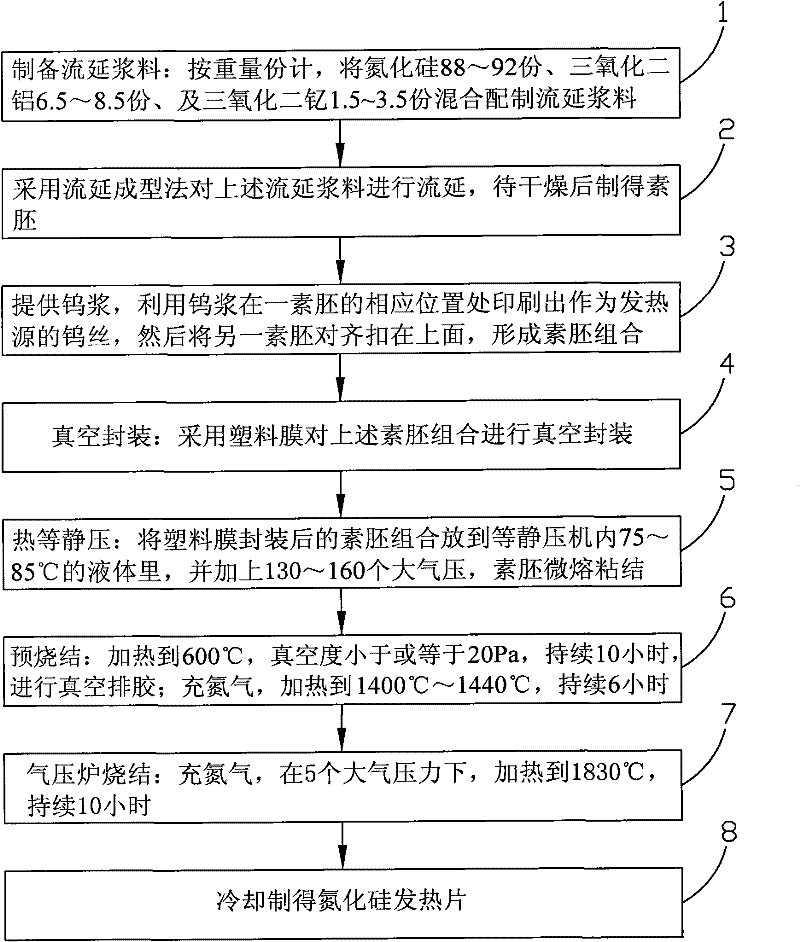

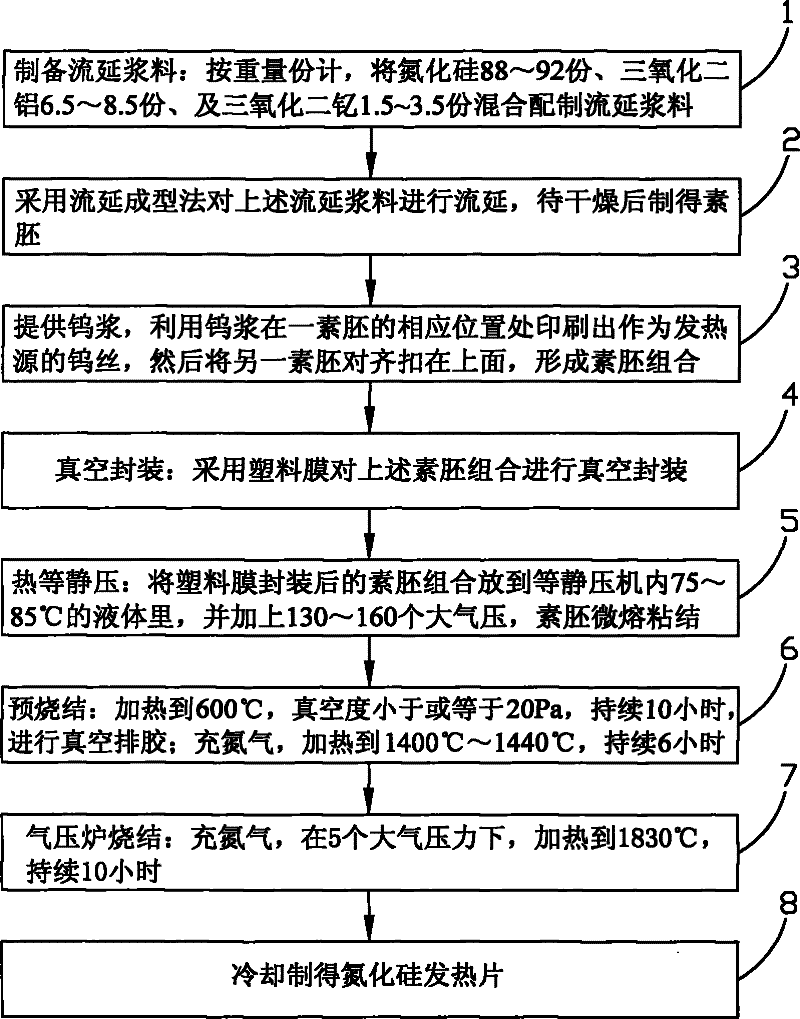

Method used

Image

Examples

Embodiment 1

[0035] Preparation of casting slurry: 88 parts of silicon nitride, 8.5 parts of aluminum oxide, 1.5 parts of diyttrium trioxide, 1.1 parts of paraffin wax, 1.7 parts of microcrystalline wax, 0.1 part of stearin wax, and 6.5 parts of plastic are provided in parts by weight The raw material for making the silicon nitride heating sheet is prepared into casting slurry; wherein, the plastic can be selected from one of PE, PP, HIPS, PET or a combination thereof.

[0036] The casting slurry was casted by a casting machine by a tape casting method, and dried at 60° C. for 2 hours at the same time to obtain a blank of a silicon nitride heating sheet.

[0037] Provide tungsten paste, use tungsten paste to print a tungsten wire as a heat source at the corresponding position of a blank, and then align and buckle another blank on top to form a blank combination.

[0038] Vacuum packaging: use plastic film to vacuum package the combination of the above blanks.

[0039] Hot isostatic pressi...

Embodiment 2

[0043] Preparation of casting slurry: 90 parts of silicon nitride, 7.5 parts of aluminum oxide, 3.5 parts of diyttrium trioxide, 1.7 parts of paraffin wax, 1.4 parts of microcrystalline wax, 0.3 part of stearin wax, and 7.5 parts of plastic are provided in parts by weight The raw materials for making the heating body are formulated into slurry; the plastic can be selected from one of PE, PP, HIPS, PET or a combination thereof.

[0044] The casting slurry was casted by a casting machine by a tape casting method, and dried at 90° C. for 1.5 hours at the same time to obtain a blank of a silicon nitride heating sheet.

[0045] Provide tungsten paste, use tungsten paste to print a tungsten wire as a heat source at the corresponding position of a blank, and then align and buckle another blank on top to form a blank combination.

[0046] Vacuum packaging: use plastic film to vacuum package the combination of the above blanks.

[0047] Hot isostatic pressing: put the green embryos pa...

Embodiment 3

[0051] Preparation of casting slurry: 92 parts of silicon nitride, 6.5 parts of aluminum oxide, 2.5 parts of diyttrium trioxide, 1.4 parts of paraffin wax, 1.7 parts of microcrystalline wax, 0.2 parts of stearin wax, and 7 parts of plastic are provided in parts by weight The raw materials for making the heating body are formulated into slurry; the plastic can be selected from one of PE, PP, HIPS, PET or a combination thereof.

[0052] The casting slurry was casted by a casting machine by a tape casting method, and dried at 120° C. for 1 hour at the same time to obtain a blank of a silicon nitride heating sheet.

[0053] Provide tungsten paste, use tungsten paste to print tungsten wire as a heat source at the corresponding position of one blank, and then align and buckle another blank on top to form a blank combination.

[0054] Vacuum packaging: use plastic film to vacuum package the combination of the above blanks.

[0055] Hot isostatic pressing: Put the raw embryos packaged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com