Improved methods for fermentative production of docosahexaenoic acid

A technology for fermentation liquid and fermentation tank, which is applied in the field of fermentation production of docosahexaenoic acid, and can solve the problems of optimizing productivity and controlling pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Solid state fermentation to produce DHA

[0060] Mix 30ml of water with 100g of coarse Ragi (finger millet) powder and autoclave. 2 g of glucose, 2 g of glycerol and 0.02 g of amylase were dissolved in 100 ml of water and autoclaved. Inoculate 10 ml of the seed solution prepared in Example 1 into 100 ml of aqueous medium, and mix thoroughly in a vortex mixer. Pour the contents into the sterilized Ragi powder and mix well. The mixed solid matrix was spread on trays in a layer thickness of 3 mm. Place the tray in an incubator with sterile gas, and control the temperature below 26°C for 120 hours.

[0061]Remove the tray, spread out the solid medium from the tray, mix well and grind. The ground solid was loaded onto a column containing methanol. The solid matrix was thoroughly soaked in methanol for 16 hours, and the methanol was collected. Re-extraction with methanol was performed by soaking for 8 hours, and the methanol layer was collected. The methanol layers wer...

Embodiment 2

[0063] Production of DHA by Solid State Fermentation ATCC PRA 148

[0064] (A) Starting seed culture - Thraustochytrid ATCC PRA 148

[0065] 100 ml of seed medium was prepared in a 250 ml Erlenmeyer flask containing 100 ml of water, 5 g of glucose, 0.5 g of yeast extract, 3.5 g of soy flour and 4.0 g of sea salt. Adjust the pH to 5 and autoclave. A full circle of Thraustochytrium ATCC PRA 148 was transferred to the flask and incubated at 22° C., 220 RPM for 72 hours.

[0066] (B) Solid-state fermentation to produce DHA

[0067] Mix 50ml of water with 100g of coarse rice flour and autoclave. 2 g of glucose, 2 g of glycerin, 3 g of soy peptone and 0.02 g of amylase were dissolved in 100 ml of water and autoclaved. Inoculate 10 ml of the seed solution prepared in Example 1 (A) into 100 ml of aqueous medium, and mix thoroughly in a vortex mixer. Pour the contents into the sterilized rice and mix well. The mixed solid matrix was spread on trays in a layer thickness of 3 mm. ...

Embodiment 3-

[0069] Example 3 - Fermentation of sucrose

[0070] (A) Starting seed culture - Schizochytrium limacinum ATCC MYA 1381

[0071] 100 ml of seed medium was prepared in a 250 ml Erlenmeyer flask containing 100 ml of water, 0.2 g of glucose, 2 g of sucrose, 0.25 g of yeast extract, 4 g of soybean flour and 3.2 g of sea salt. Adjust the pH to 7.5 with 1 N NaOH and autoclave. A full circle of Schizochytrium ATCC MYA 1381 was transferred to the flask and cultured at 22° C. and 220 RPM for 48 hours.

[0072] Prepare a 750 ml seed culture in a 1000 ml Erlenmeyer flask containing 750 ml water, 1.5 g glucose, 15 g sucrose, 7 g starch, 2 g bacterial amylase, 1.125 g yeast extract, 30 g soybean flour, 1.125 g diammonium phosphate and 24 g sea salt base. Adjust the pH to 7.5 with 1 N NaOH and autoclave. 7.5 ml of seed solution prepared from a 100 ml seed flask was inoculated therein. The flask was placed in a shaker and incubated at 24°C for 58 hours.

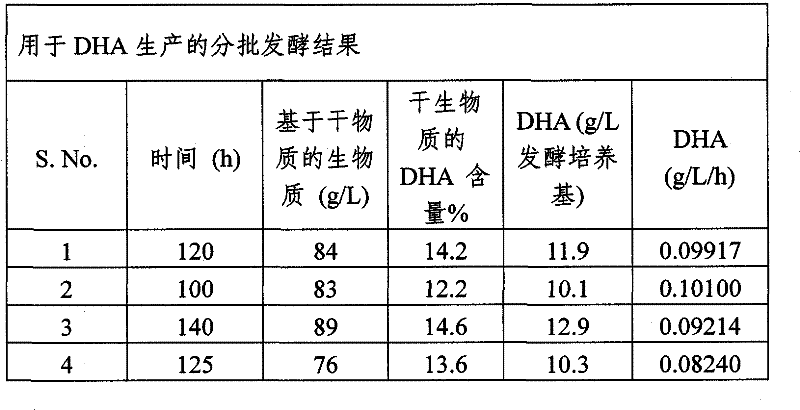

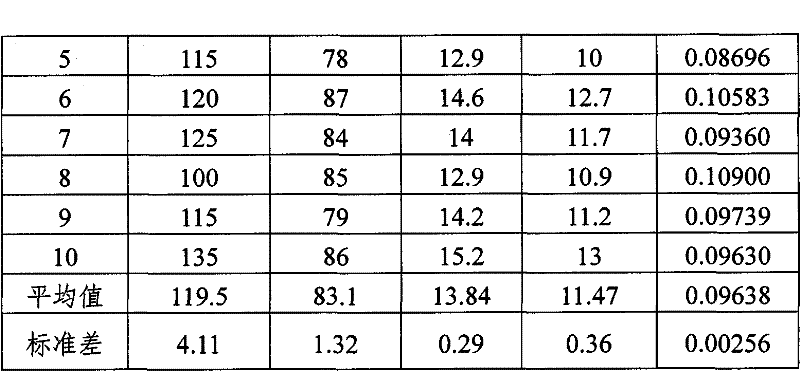

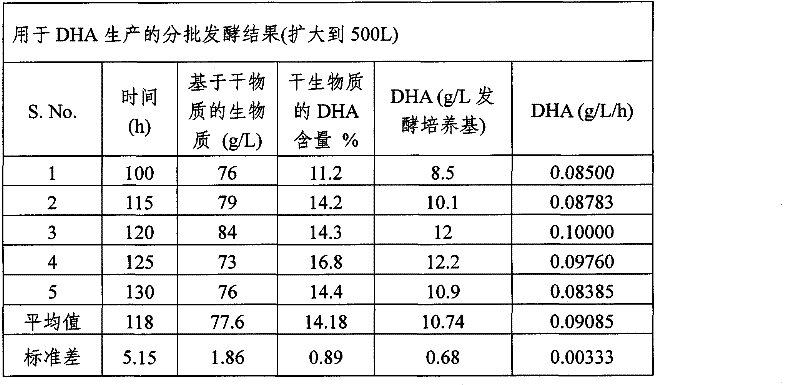

[0073] (B) Submerged batch ferm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com