Asparagus saponin oral liquid and preparation method thereof

A saponin oral liquid and a technology for the oral liquid are applied in the field of asparagus saponin oral liquid and its preparation, and achieve the effects of fragrant aroma, outstanding health care function and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

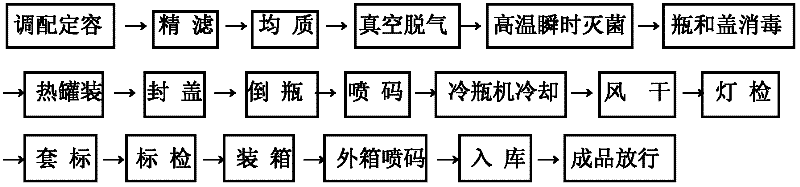

Method used

Image

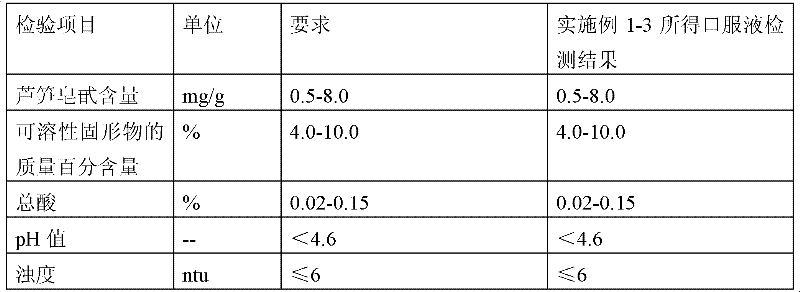

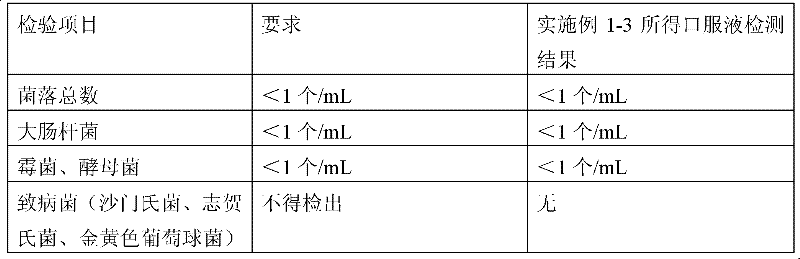

Examples

Embodiment 1

[0035]1) Mix the following components by weight and adjust to a constant volume to obtain a formulated solution: 0.15% asparagus saponin, 0.06% black tea powder, 4.00% sweetener white sugar, 0.07% sour taste regulator, 0.30% honey, stable Carboxymethylcellulose sodium 0.15%, antioxidant sodium ascorbate 0.003%, food coloring caramel coloring 0.015%, food flavoring 0.05%, and other pure water to make up to volume;

[0036] Among them, the preparation and constant volume steps are as follows: ① Accurately weigh each raw material according to the above formula for use; ② Mix the dry ingredients of sweetener and stabilizer evenly, pour them into the batching tank, and then add 6-8 times 60- 80°C pure water, stirred at high speed until completely dissolved, then filtered through a 200-mesh filter cloth and transferred to the blending tank; ③Dissolve other raw materials except essence with 40-50°C pure water, and transfer to the blending tank, Turn on the stirring; ④ add pure water ...

Embodiment 2

[0040] 1) Mix the following components by weight and prepare to a constant volume to obtain a preparation solution: 0.20% asparagus saponin, 0.10% black tea powder, 4.50% white sugar as a sweetener, 0.09% citric acid as a sour taste regulator, and 0.20% refined honey %, stabilizer sodium carboxymethyl cellulose 0.22%, antioxidant sodium ascorbate 0.004%, food coloring caramel pigment 0.012%, food flavor 0.08%, and other pure water to make up to volume;

[0041] Among them, the preparation and constant volume steps are as follows: ① Accurately weigh each raw material according to the above formula for use; ② Mix the dry ingredients of white granulated sugar and stabilizer evenly, pour them into the batching tank, and then add 6-8 times 60-80 ℃ of pure water, stir at high speed until completely dissolved, then filter through a 200-mesh filter cloth and transfer to the blending tank; ③ Dissolve other raw materials except essence with 40-50 ℃ of pure water, transfer to the blending...

Embodiment 3

[0045] 1) Mix the following components by weight and adjust to a constant volume to obtain a mixed solution: 0.40% asparagus saponin, 0.15% black tea powder, 3.00% white sugar as a sweetener, 0.06% citric acid as a sour taste regulator, and 0.40% refined honey %, stabilizer sodium carboxymethyl cellulose 0.18%, antioxidant sodium ascorbate 0.005%, food coloring caramel pigment 0.008%, food flavor 0.10%, and other pure water to make up to volume;

[0046] Wherein, the preparation and constant volume steps are as follows: ① Accurately weigh each raw material according to the above formula for use; 8 times of pure water at 60-80°C, stirred at high speed until completely dissolved, then filtered through a 200-mesh filter cloth and transferred to the blending tank; In the blending tank, turn on the stirring; ④ add pure water to constant volume, reserve an appropriate amount of space for subsequent adjustments; ⑤ check the sugar content and pH value after stirring evenly, add flavor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com