Method for reducing production energy consumption of sulfuric acid and phosphoric acid

A technology of sulfuric acid and phosphoric acid, applied in chemical instruments and methods, phosphorus compounds, sulfur compounds, etc., can solve the problems of large cooling water consumption, large steam consumption, heat waste, etc., to reduce equipment investment and floor space, technology Easy transformation, simple and practical technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

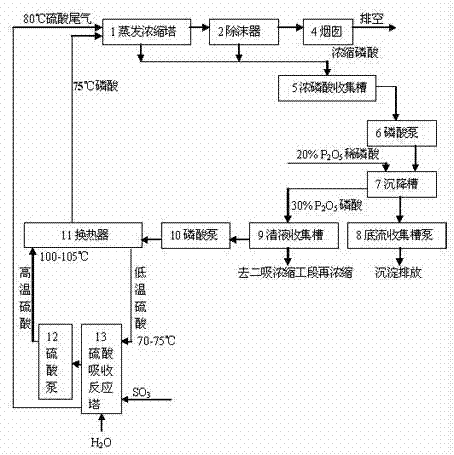

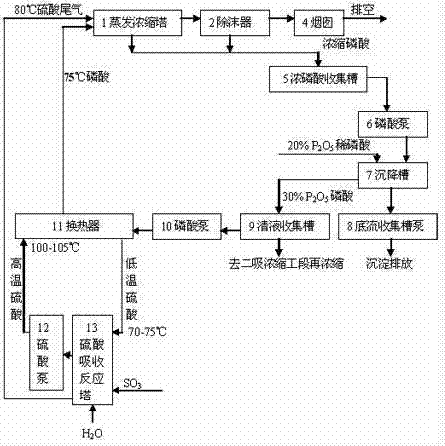

[0035] see figure 1 : The method for reducing the energy consumption of sulfuric acid and phosphoric acid production is to link the sulfuric acid system with the phosphoric acid system, use dilute phosphoric acid as the cooling medium, replace the cooling water, and cool the sulfuric acid, thereby reducing the energy consumption of sulfuric acid; meanwhile, dilute phosphoric acid is replaced by sulfuric acid Heating, use the exhaust gas from the outlet of the sulfuric acid second absorption tower to evaporate the water, increase the concentration, and no longer use steam, thereby reducing the energy consumption of phosphoric acid.

[0036] The method includes a sulfuric acid absorption reaction process and a phosphoric acid concentration process, wherein

[0037] The concrete steps of sulfuric acid absorption reaction process are:

[0038] (1). H 2 O adds sulfuric acid absorption reaction tower 1;

[0039] (2). Put SO 3 The gas is sent to sulfuric acid absorption reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com