Polyaryletherketone/polyaniline-carbon nanotube composite material with high dielectric property and preparation method thereof

A technology of carbon nanotubes and polyaryletherketone, which is applied in the field of polymer-based nanocomposites and its preparation, can solve the problems of dielectric materials without embedded capacitors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

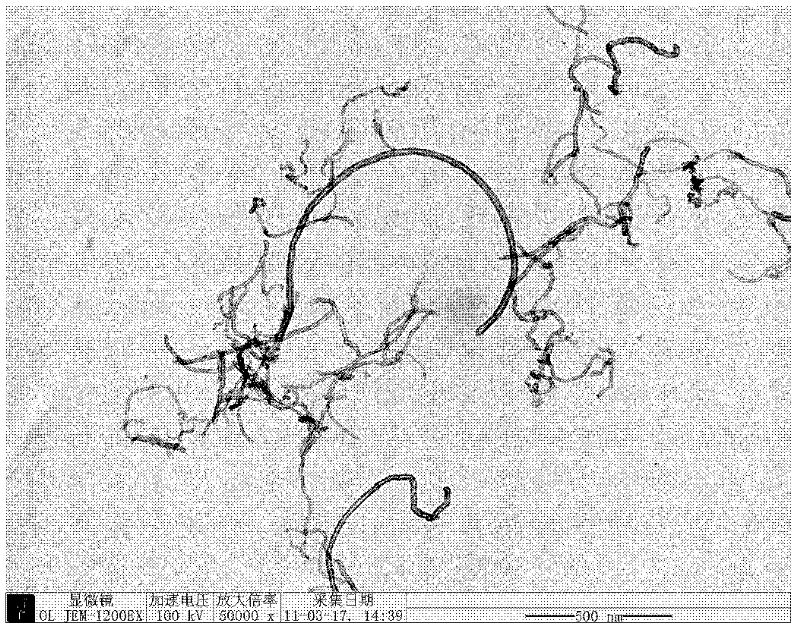

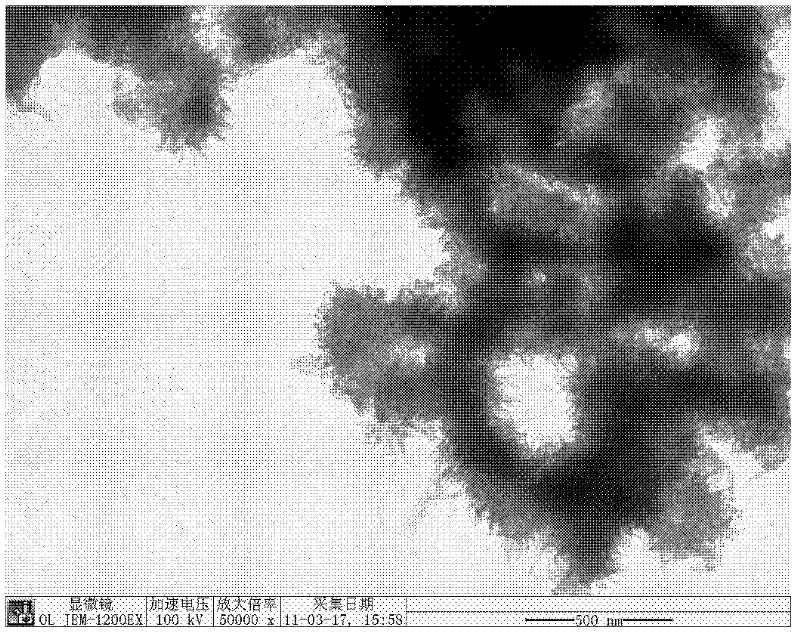

[0021] 0.1 gram of polyaniline-carbon nanotubes (aniline: carbon nanotubes = 8: 2, see figure 2 ) in 2ml NMP for 2 hours to make it evenly dispersed; at the same time, dissolve 0.9 g of sulfonated polyetheretherketone (x / y=20 / 80) in 5ml of NMP; then mix the two solutions together and continue to sonicate for 1 hour Finally, it is casted on a smooth glass plate, dried at 80°C, and then vacuum-dried at 120°C for 24 hours to obtain a high dielectric constant polyaryletherketone / carbon nanotube composite material.

[0022] The dielectric properties of the material were measured, the dielectric constant ε=15, and the dielectric loss 0.11 (test temperature 25° C., test frequency 1000 Hz).

Embodiment 2

[0024] With 0.2 gram of polyaniline-carbon nanotubes (aniline: carbon nanotubes = 8: 2, see figure 2 ) in 4ml NMP for 2 hours to make it evenly dispersed; at the same time, dissolve 0.8 g of sulfonated polyetheretherketone (x / y=20 / 80) in 4ml of NMP; then mix the two solutions together and continue to sonicate for 1 hour Finally, it is cast on a smooth glass plate, dried at 80°C, and then vacuum-dried at 120°C for 24 hours to obtain a high dielectric constant polyaryletherketone / carbon nanotube composite material.

[0025] The dielectric properties of the material were measured, the dielectric constant ε=159, and the dielectric loss 0.34 (test temperature 25° C., test frequency 1000 Hz).

Embodiment 3

[0027] With 0.3 gram of polyaniline-carbon nanotubes (aniline: carbon nanotubes = 8: 2, see figure 2 ) in 4ml NMP for 2 hours to make it uniformly dispersed; at the same time, dissolve 0.7 g of sulfonated polyetheretherketone (x / y=20 / 80) in 5ml of NMP; then mix the two solutions together and continue to sonicate for 1 hour Finally, it is cast onto a smooth glass plate, dried at 70°C, and then vacuum-dried at 130°C for 16 hours.

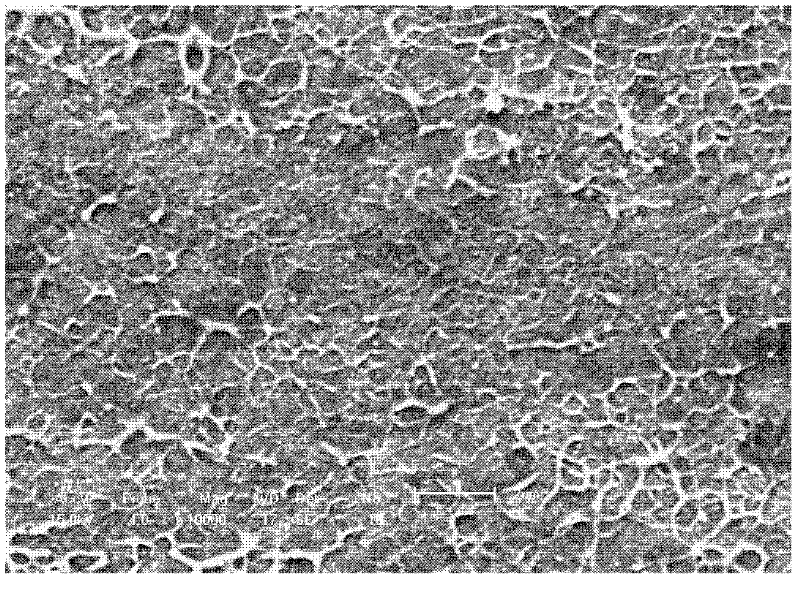

[0028] The morphology of the prepared high dielectric constant polyaryletherketone / carbon nanotube composites is shown in image 3 , to measure the dielectric properties of the material, the dielectric constant ε=1002, and the dielectric loss 3.19 (test temperature 25° C., test frequency 1000 Hz).

[0029]Select the reported sulfonated polyether ether ketone / carbon nanotube (mass ratio 94 / 6) composite material to compare with the material of this example. The carbon nanotube content of this composite material is also 6%. Since there is no polyanilin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com