Carbon material coated with diamond thin film and method for producing same

A manufacturing method and diamond technology, applied in the direction of diamond, metal material coating process, thin material processing, etc., can solve the problems of stress, poor thermal expansion coefficient, peeling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A carbon material produced by the method shown in the detailed description was used.

[0053] The carbon material produced in this way is hereinafter referred to as the present invention material A1.

[0054] In addition, among the carbonaceous substrates, the carbonaceous substrate I which is the most easily etched was used.

Embodiment 2

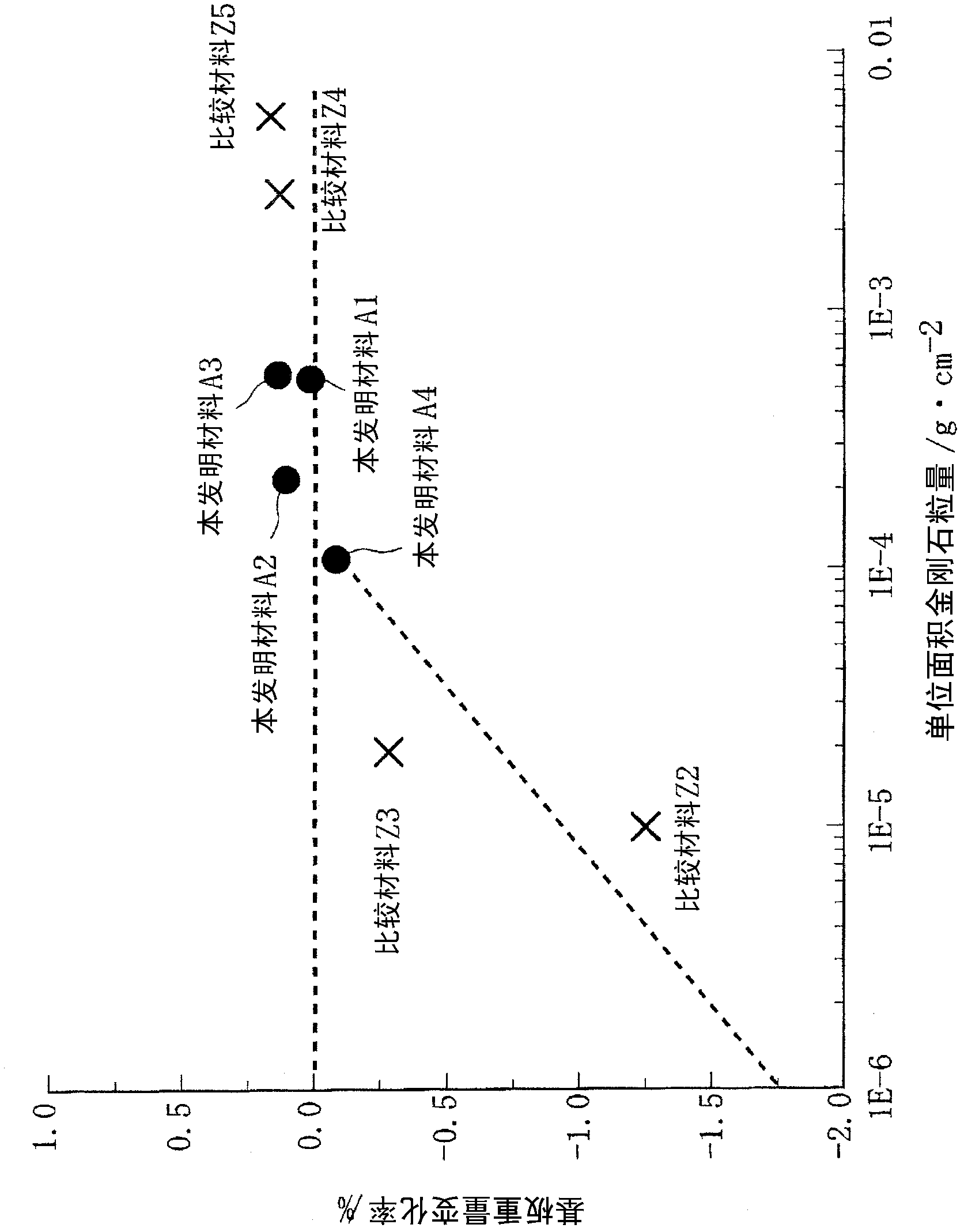

[0056] The ratio of the diamond grains in the ethanol solution was set to 1.0% by weight, and the carbonaceous material was produced in the same manner as in Example 1 above, except that the diamond grains were added to the carbonaceous substrate 1 by a spray coating method.

[0057] Hereinafter, the carbon material produced in this way is called this invention material A2.

[0058] In addition, when diamond grains were added to the carbonaceous substrate, the concentration of diamond grains on the surface of the substrate was 5.7×10 -4 g / cm 2 .

[0059] In addition, when Raman spectrum analysis is carried out to the obtained diamond thin film, at 1333cm -1 Diamond-induced peaks were observed at . Furthermore, SEM observation of the obtained diamond thin film confirmed that the surface of the base material was covered with the diamond thin film and that it was a polycrystalline film composed of self-shaped diamond grains with a grain size of about 1 μm.

Embodiment 3

[0061] A carbon material was produced in the same manner as in Example 1 above except that the ratio of the diamond grains in the ethanol solution was 2.0% by weight.

[0062] Hereinafter, the carbon material produced in this way is called this invention material A3.

[0063] In addition, when diamond grains are added to the carbonaceous substrate, the concentration of diamond grains on the surface of the substrate is 6.0×10 -4 g / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com