Method for preparing graphene and inorganic salt high-temperature phase change composite material

A composite material and high-temperature phase change technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of easy agglomeration of graphene, etc., and achieve the effect of high energy storage density, large phase change heat, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

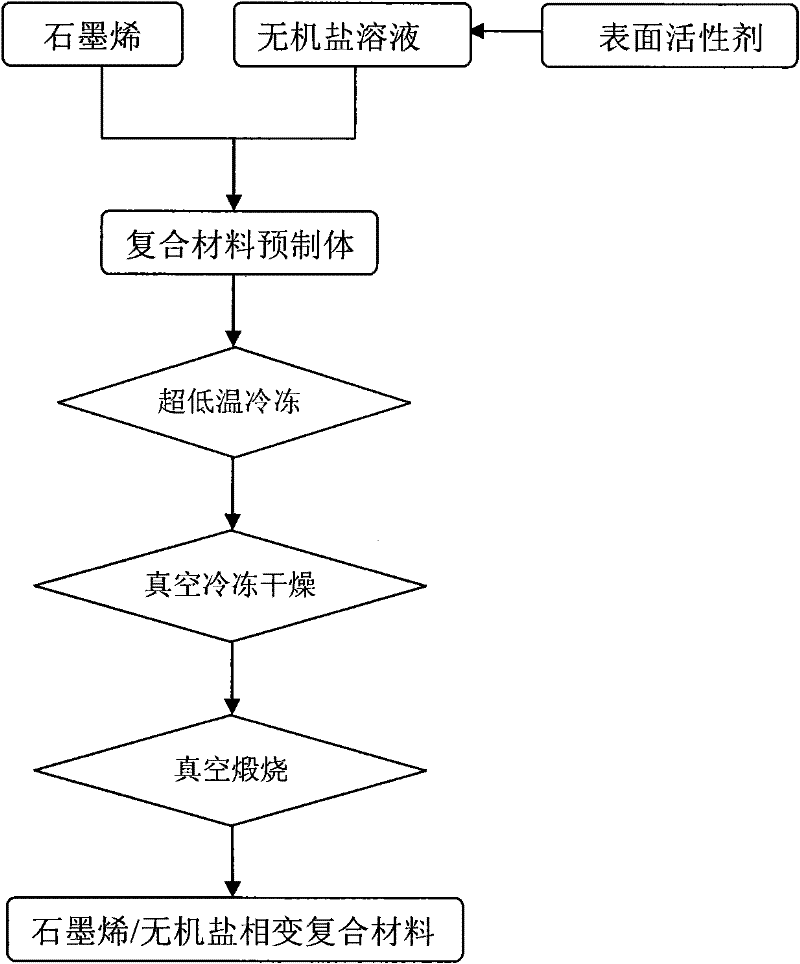

[0028] A kind of preparation method of graphene / inorganic salt high-temperature phase-change composite material, its technological process is as follows figure 1 As shown, the method includes the following steps:

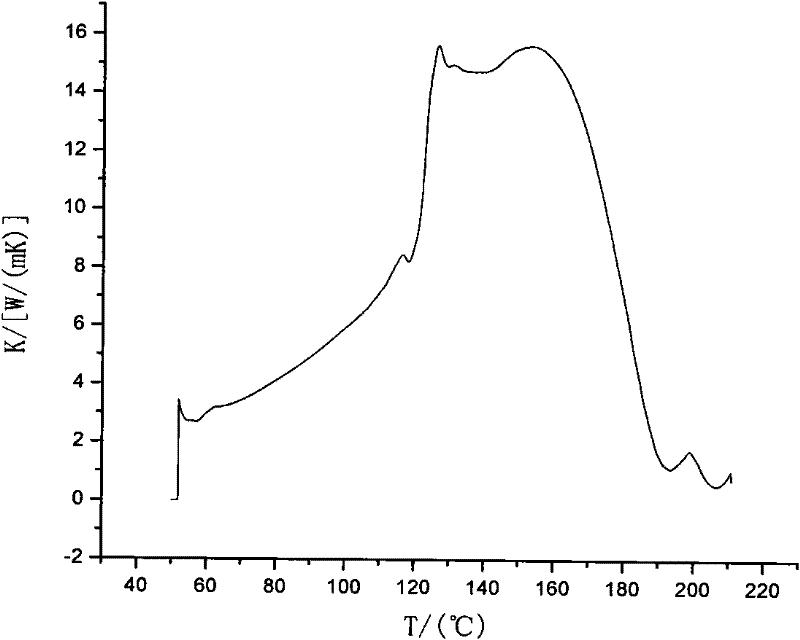

[0029] According to the mass ratio of 5.5:4.5, weigh 1.10g LiNO with YP102N electronic balance 3 , 0.90g NaNO 3 Configure 250ml of 8mg / ml mixed nitrate solution. Take 10ml of 8mg / ml mixed nitrate solution, add a certain amount of surfactant sodium dodecyl sulfate SDS, and stir until the mixture is uniform. Stir with a constant temperature magnetic stirrer for 20 minutes, and ultrasonically disperse for 20 minutes. Measure 20 ml of 1 mg / ml reduced graphene oxide sol, add it to the above mixed solution, and stir rapidly until the reduced graphene oxide sol is uniformly dispersed in the mixed solution to obtain a composite material preform.

[0030] Put the composite material preform in a plastic box covered with tinfoil, seal it with plastic wrap, and put it into ...

Embodiment 2

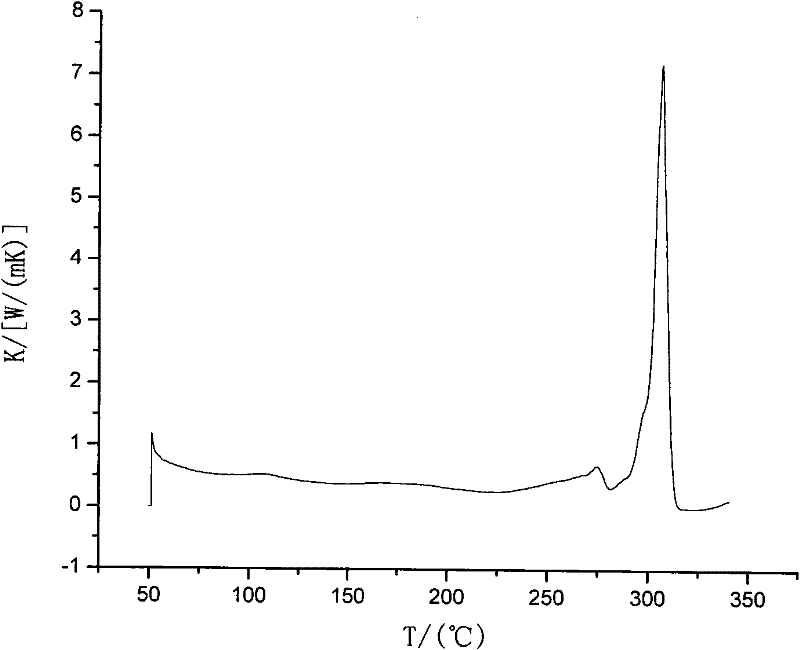

[0033] Weigh 2.25gKNO with YP102N electronic balance 3 Configure 9mg / ml KNO 3 Solution 250ml; Take 9mg / ml KNO 3 Solution 10ml, add a certain amount of surfactant sodium dodecyl sulfate SDS, stir until mixed evenly. Stir with a constant temperature magnetic stirrer for 20 minutes, and ultrasonically disperse for 20 minutes; measure 10 ml of 1 mg / ml reduced graphene oxide sol, add it to the above mixed solution, and stir rapidly until the reduced graphene oxide sol is evenly dispersed in the mixed solution to obtain a composite material preform.

[0034] Put the composite material preform in a plastic box covered with tinfoil, seal it with plastic wrap, and put it into an ultra-low temperature freezer for quick freezing while keeping it level. When the liquid mixture is frozen into a solid state, take it out, seal the plastic box with tinfoil instead of plastic wrap, poke a few fine holes on the tinfoil cover, put it into a vacuum freeze-drying and dispersing device for vacuum...

Embodiment 3

[0037] Such as figure 1 Shown, a kind of graphene / inorganic salt high-temperature phase-change composite material and preparation method thereof, the method comprises the following steps:

[0038] Weigh 2.00gKNO with YPl02N electronic balance 3 Configure 8mg / ml KNO 3 Solution 250ml; Take 8mg / ml KNO 3 Solution 10ml, add a certain amount of surfactant sodium dodecyl sulfate SDS, stir until evenly mixed; stir with a constant temperature magnetic stirrer for 20min, ultrasonically disperse for 20min; measure 1mg / ml reduced graphene oxide sol 20ml, add the above mixed solution , stirring rapidly until the reduced graphene oxide sol is uniformly dispersed in the mixed solution to obtain a composite material preform.

[0039] Put the composite material prefabricated body in a plastic box covered with tinfoil, seal it with plastic wrap, put it into an ultra-low temperature freezer for quick freezing, and keep it level; when the liquid mixture freezes into a solid state, take it out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com