Rheotaxial preparation method of gallium antimonide quantum dot

A liquid phase epitaxy, gallium antimonide technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as high toxicity and high cost, and achieve low production cost, wide application prospects, and uniform size distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

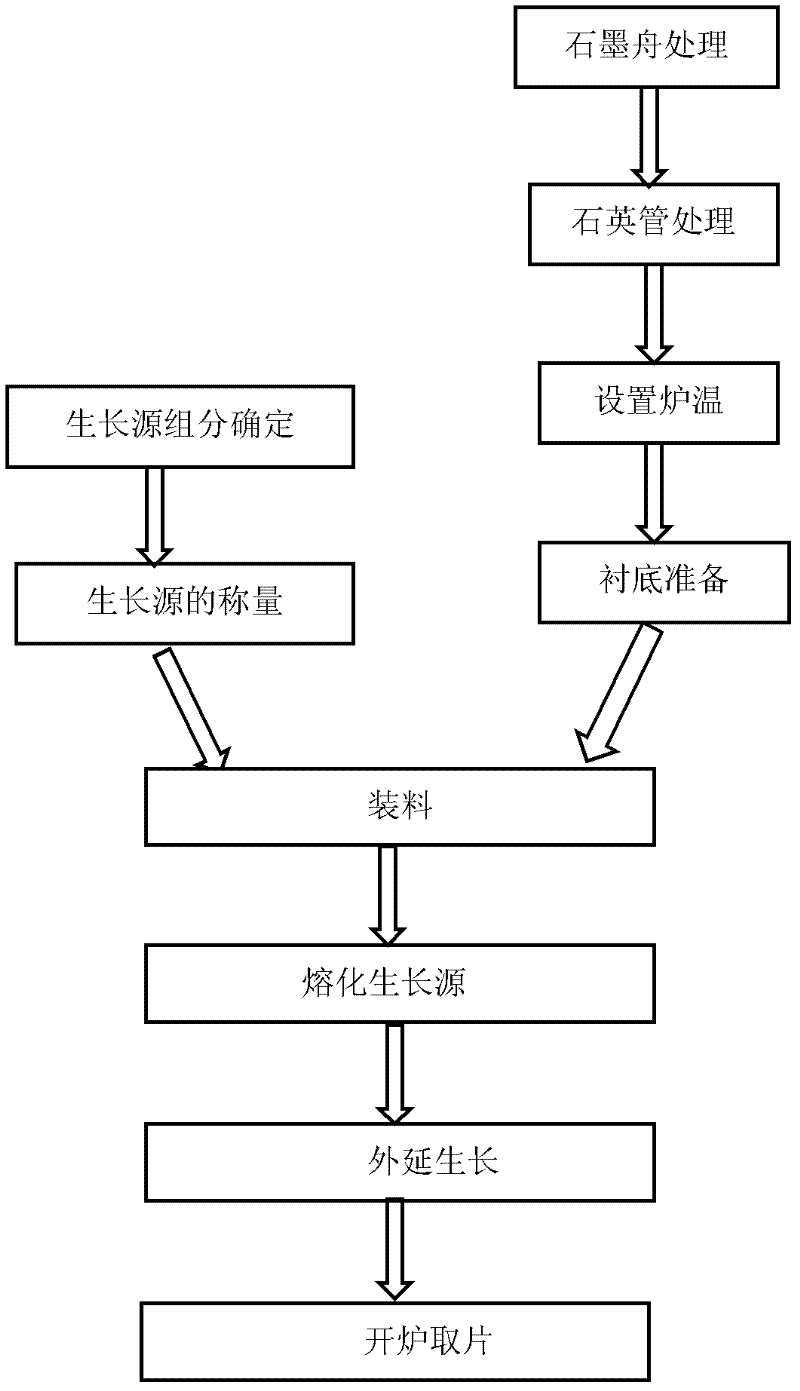

[0026] 1. Configuration of growth source

[0027] Composition determination: the epitaxial growth temperature in the present invention is 575° C., the mole percentage of gallium is 0.8, and the mole percentage range of antimony (Sb) is 0.2. According to the size of the graphite liquid tank and the molar percentage and molar weight of the above-mentioned growth sources, the required amount of antimony (Sb) and gallium (Ga) can be obtained.

[0028] (2) Weighing of growth source: According to the above calculation, use a microbalance to accurately weigh the antimony (Sb) source and gallium (Ga) source required for growth. The used antimony (Sb) source and gallium (Ga) source are all 99.99999% (7N) high-purity elemental sources.

[0029] 2. Preparatory work before epitaxial growth

[0030] (1) Graphite boat treatment. In order to avoid pollution from growth sources, the boat should be very clean. Before use, it should be soaked in aqua regia for 24 hours to remove impurities, ...

Embodiment 2

[0042] 1. Configuration of growth source

[0043] (1) Composition calculation: the epitaxial growth temperature in the present invention is 570° C., the mole percentage range of gallium is 0.85, and the mole percentage range of antimony (Sb) is 0.15. According to the size of the graphite liquid tank and the molar percentage and molar weight of the above-mentioned growth sources, the required amount of antimony (Sb) and gallium (Ga) can be obtained.

[0044] (2) Weighing of growth source: According to the above calculation, use a microbalance to accurately weigh the antimony (Sb) source and gallium (Ga) source required for growth. The used antimony (Sb) source and gallium (Ga) source are all 99.99999% (7N) high-purity elemental sources.

[0045] 2. Preparatory work before epitaxial growth

[0046] (1) Graphite boat treatment. In order to avoid pollution from growth sources, the boat should be very clean. Before use, it should be soaked in aqua regia for 24 hours to remove im...

Embodiment 3

[0058] 1. Configuration of growth source

[0059] (1) Determination of growth source components: the epitaxial growth temperature in the present invention is 565° C., the mole percentage of gallium is 0.9, and the mole percentage of antimony (Sb) is 0.1. According to the size of the graphite liquid tank and the molar percentage and molar weight of the above-mentioned growth sources, the required amount of antimony (Sb) and gallium (Ga) can be obtained.

[0060] (2) Weighing of growth source: According to the above calculation, use a microbalance to accurately weigh the antimony (Sb) source and gallium (Ga) source required for growth. The used antimony (Sb) source and gallium (Ga) source are all 99.99999% (7N) high-purity elemental sources.

[0061] 2. Preparatory work before epitaxial growth

[0062] (1) Graphite boat treatment. In order to avoid pollution from growth sources, the boat should be very clean. Before use, it should be soaked in aqua regia for 24 hours to remov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com