Preparation method of ultra-high crosslinking type adsorptive resin modified by N-methyl acetamido

A methylacetamide-based, ultra-high cross-linking technology, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal oxides/hydroxides, etc., can solve the reduction of resin specific surface area, adverse adsorption, functional The problem of weak interaction between the base nitrogen atom and the adsorbate can achieve the effect of improving the ability of selective adsorption and improving the adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

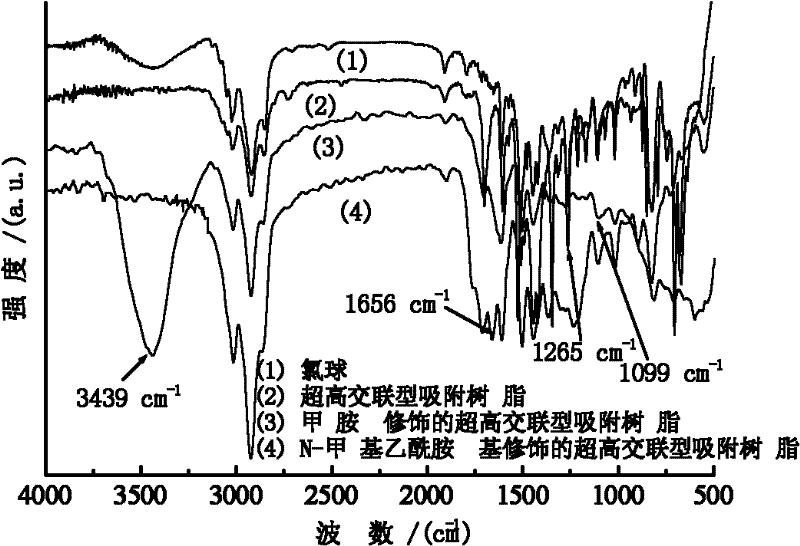

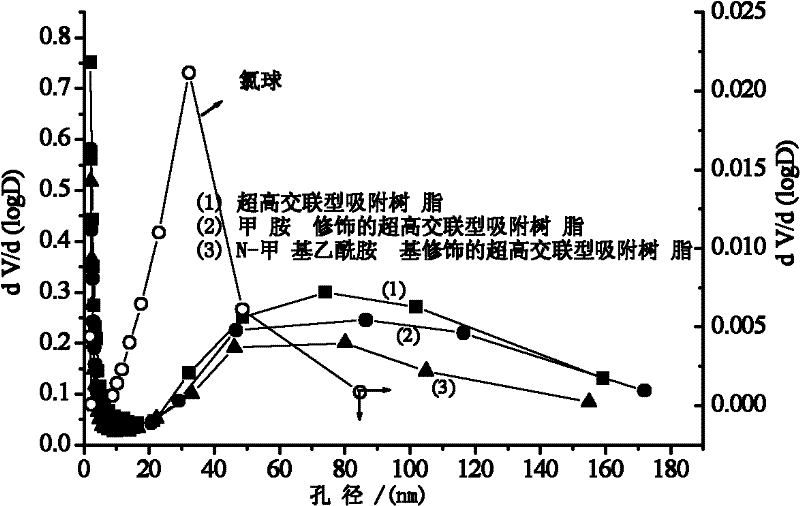

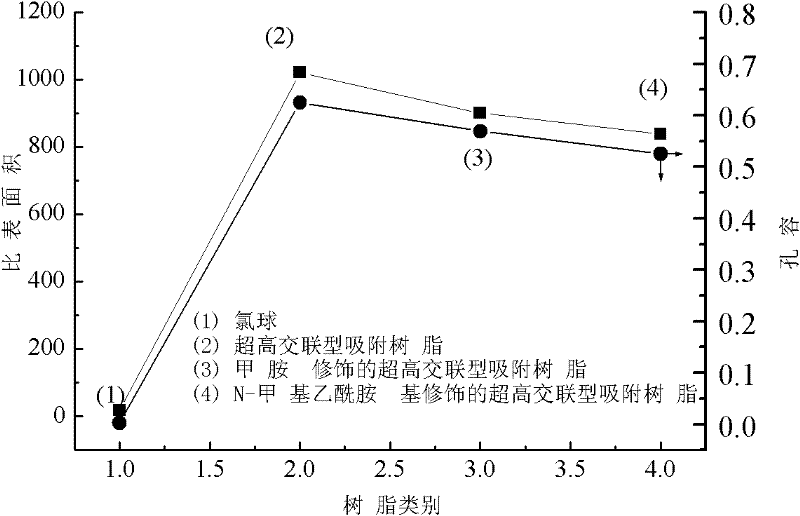

Embodiment 1

[0049] Friedel-Crafts reaction: In a 250ml three-necked bottle, add 22.5g of dry chlorine balls with a chlorine content of 17.3% and a crosslinking degree of 6% (provided by Hebei Langfang Electric Power Resin Factory), add 120ml of dichloroethane, and swell at room temperature 17h; warm up to 50°C, add 5.4g FeCl 3 , stirred until the FeCl 3 Dissolve completely, gradually raise the temperature to 85°C, and react at a constant stirring speed for 9 hours to obtain an ultra-high cross-linked adsorption resin. After the reaction, the mother liquor was poured out, washed alternately with 1% hydrochloric acid aqueous solution and ethanol for several times until the eluate was clear, then transferred to a Soxhlet extractor, and extracted with ethanol for 8 hours. The resin was transferred and dried under vacuum. The determination of chlorine content records that the residual chlorine content of resin is 3.25%, adopts Brunauer-Emmett-Teller (BET) model fitting N 2 Adsorption-desorp...

Embodiment 2

[0053] Friedel-Crafts: In a 250ml three-necked bottle, add 20.0g of dry chlorine balls with a chlorine content of 17.3% and a cross-linking degree of 6%, add 120ml of dichloroethane, and swell at room temperature for 13 hours; warm up to 50°C, add 4.8 g FeCl 3 , stirred until the FeCl 3 Completely dissolve, then gradually raise the temperature to 90°C, and react for 6 hours at a certain stirring speed to obtain an ultra-high cross-linked adsorption resin. After the reaction, pour out the reaction mother liquor, alternately wash with 1% aqueous hydrochloric acid water and ethanol several times until the eluate is clear, then transfer to a Soxhlet extractor, and extract with ethanol for 10 h. The resin was transferred and dried under vacuum. Determination of chlorine content The measured residual chlorine content of the resin is 6.15%, and the specific surface area of the resin is 908.5m 2 / g, the pore volume is 0.5256cm 3 / g.

[0054] Amination reaction: In a 250ml three...

Embodiment 3

[0057] Friedel-Crafts: In a 250ml three-neck bottle, add 21.5g of dry chlorine balls with a chlorine content of 17.3% and a cross-linking degree of 6%, add 120ml of dichloroethane, and swell at room temperature for 15 hours; heat up to 50°C, add 5.2 g FeCl 3 , stirred until the FeCl 3 Dissolve completely, gradually raise the temperature to 83°C, and react for 8 hours at a certain stirring speed to obtain an ultra-high cross-linked adsorption resin. Determination of chlorine content The measured residual chlorine content of the resin is 4.17%, and the specific surface area of the resin is 988.5m 2 / g, the pore volume is 0.6088cm 3 / g.

[0058] Amination reaction: In a 250ml three-necked flask, add 18.6g of ultra-high cross-linking resin and 80.0 ml of methylamine aqueous solution, raise the temperature to 80°C, and react for 15 hours to obtain methylamine-modified ultra-high cross-linking adsorption resin. The determination of chlorine content shows that the residual chlo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com