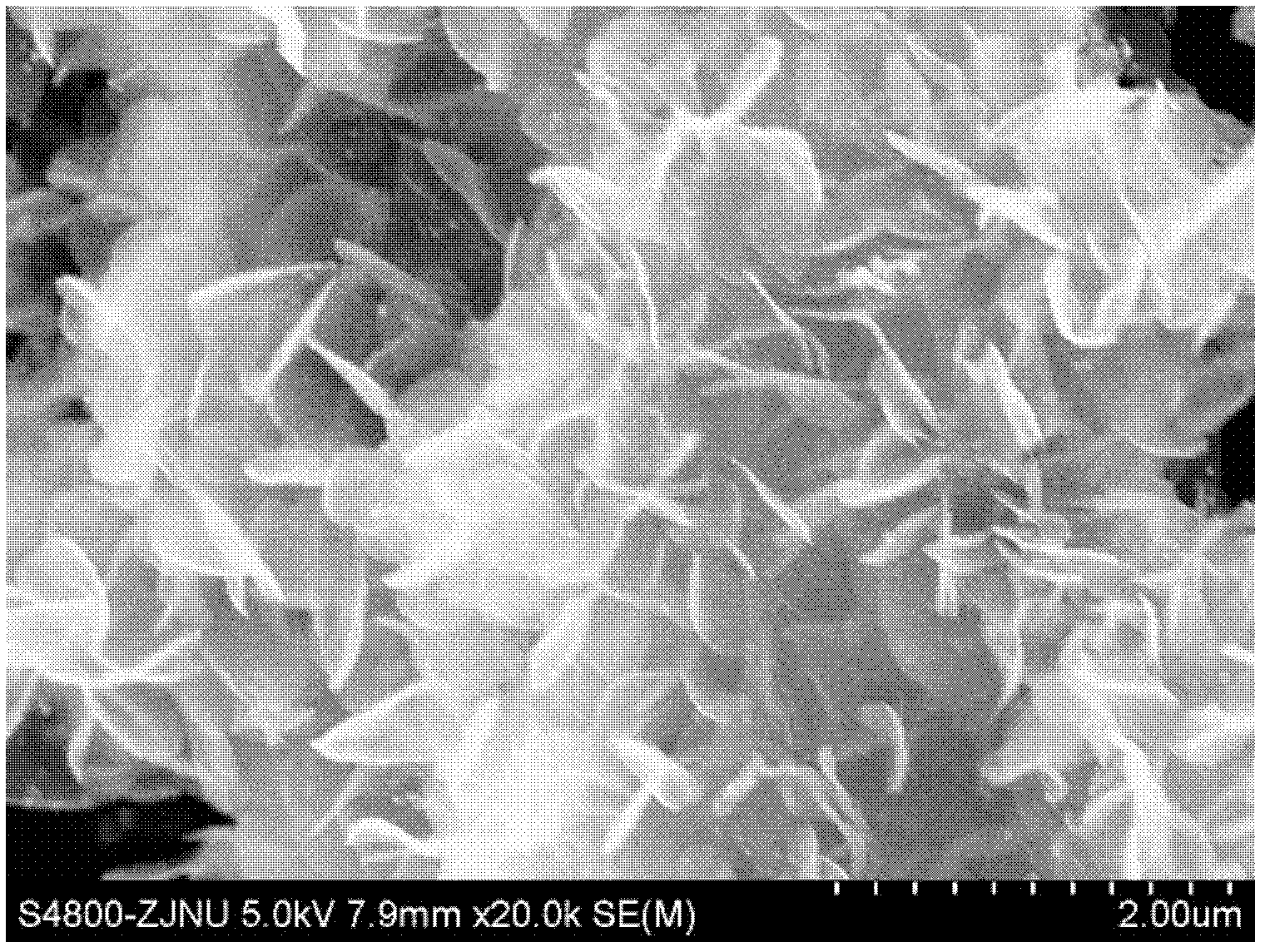

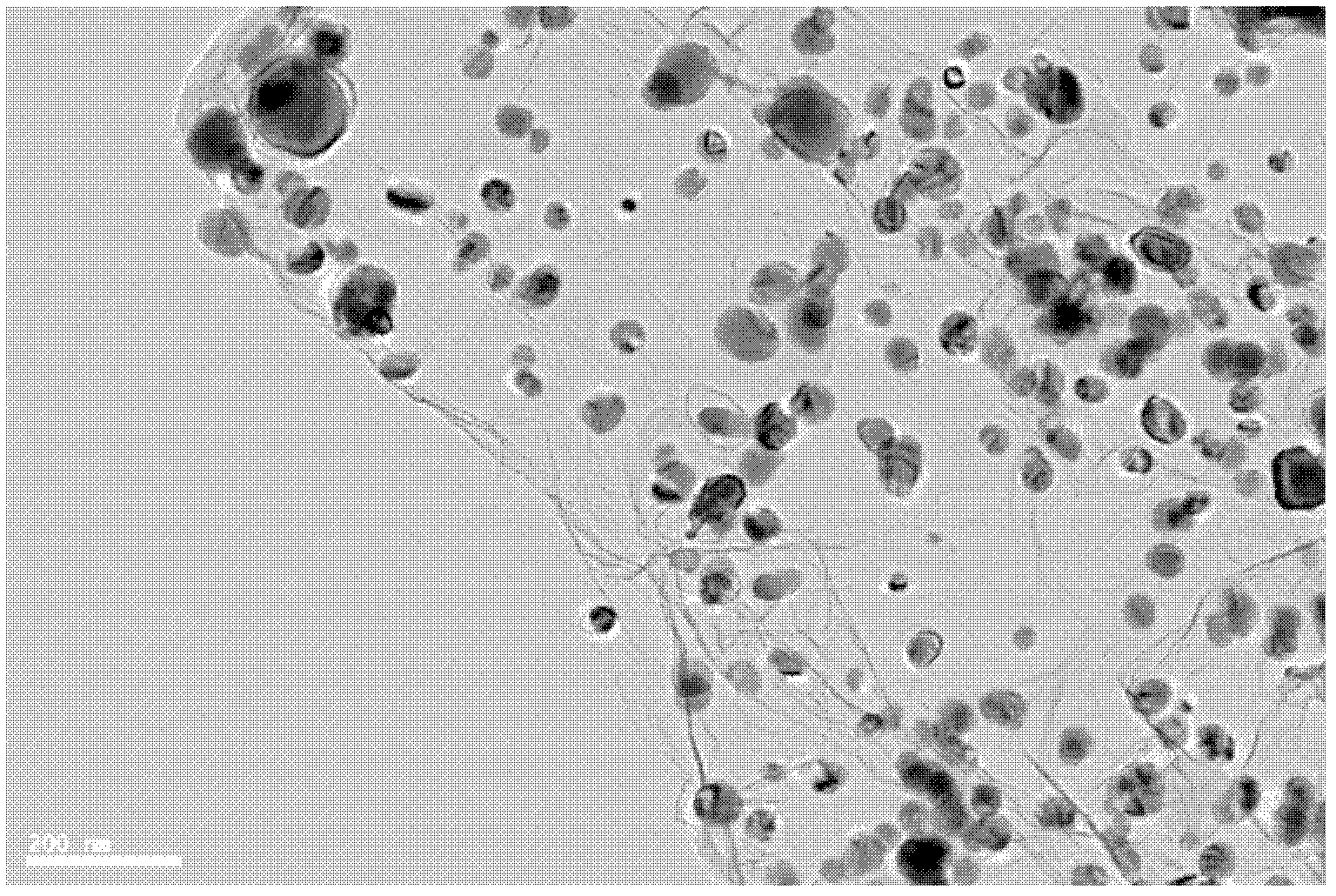

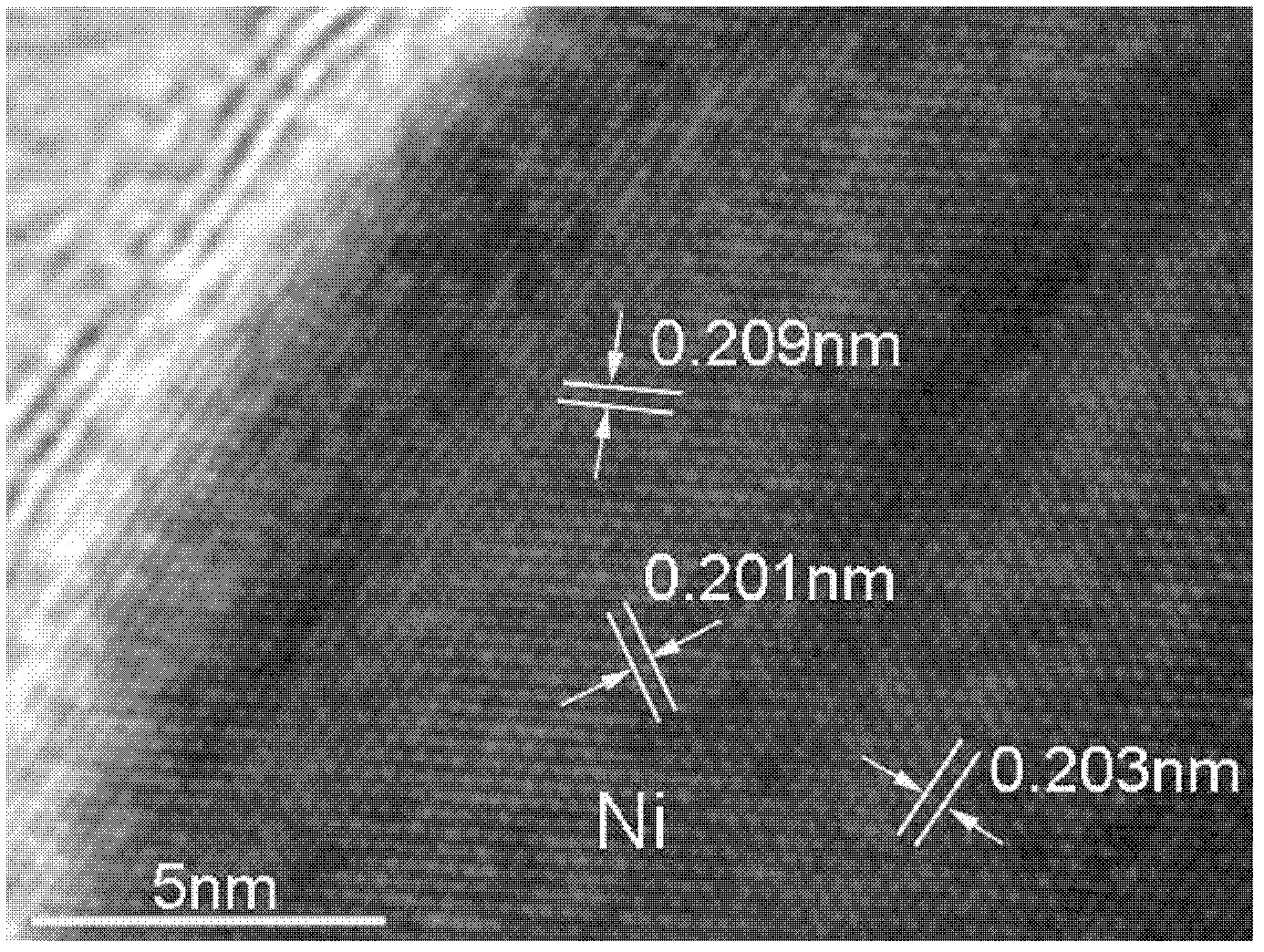

Preparation method for nickel/graphene nanometer compound material

A nanocomposite material and graphene technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve complex operation, uneven dispersion of graphene surface, low yield of metal nanoparticles, etc. problems, to achieve the effect of simple preparation process, large application potential and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of preparation method of nickel / graphene nano composite material, its preparation method comprises the following steps:

[0035] (1) Weigh 1.16g of dimethylglyoxime, dissolve it in 20ml of absolute ethanol and drop in 4ml of ammonia water, weigh nickel chloride (NiCl 2 ·6H 2 O) 1.19 g was dissolved in 5 ml of deionized water, and the above two solutions were mixed to obtain a red precipitate which was nickel dimethylglyoxime, stirred, filtered, and dried at 60° C. for 12 hours;

[0036] (2) Take by weighing the red precipitate that is dimethylglyoxime nickel 0.5g in the quartz boat, and put it into the heating furnace;

[0037] (3) feed argon to get rid of the air in the reaction chamber;

[0038] (4) React for 15 minutes at a temperature of 500° C. and an argon flow rate of 200 sccm, cool to 25° C., and collect the black powdery deposits in the quartz boat, which are nickel / graphene composite materials.

Embodiment 2

[0040] A kind of step that prepares nickel / graphene composite material as raw material with dimethylglyoxime and nickel salt is as follows:

[0041] (1) Weigh 1.74g of dimethylglyoxime, dissolve it in 30ml of absolute ethanol, drop in ammonia water 6ml, weigh nickel chloride (NiCl 2 ·6H 2 O) 1.19 g was dissolved in 5 ml of deionized water, and the above two solutions were mixed to obtain a red precipitate which was nickel dimethylglyoxime, stirred, filtered, and dried at 60° C. for 12 hours;

[0042] (2) Weigh 0.3 g of the above-prepared nickel dimethylglyoxime in a quartz boat, and put it into a heating furnace.

[0043] (3) Pass in argon gas to get rid of the air in the reaction chamber.

[0044] (4) React for 40 minutes at a temperature of 600° C. and an argon flow rate of 100 sccm, cool to 25° C., and collect the black powdery deposits in the quartz boat, which are nickel / graphene composite materials.

[0045] In specific implementation, the argon flow, reaction tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com