Wear resistant, corrosion resistant and heat resistant high-performance magnetic plastic gate valve sealing material

A sealing material and high-performance technology, applied in the field of wear-resistant, corrosion-resistant, heat-resistant, high-performance magnetic plastic door valve sealing materials, can solve the problems of unsatisfactory use, unsatisfactory demand, poor corrosion resistance, etc., achieve strong magnetism, improve Good effect of magnetism and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

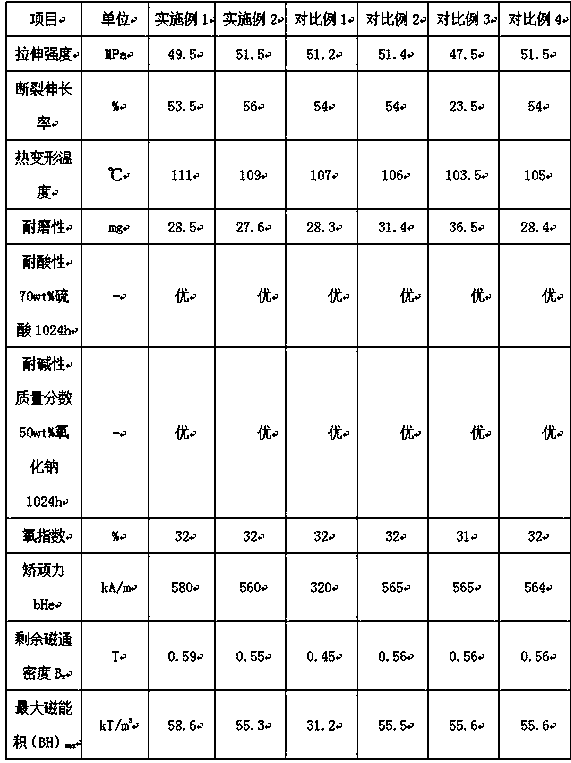

Examples

Embodiment 1

[0022] A wear-resistant, corrosion-resistant and heat-resistant high-performance magnetic plastic door valve sealing material is prepared from the following raw materials in parts by weight: 51.5 parts of ferric chloride hexahydrate, 43 parts of ethylene glycol, 4.7 parts of modified hyperbranched polyester, ethylene 128 parts of base ester resin, 11.7 parts of polyvinylpyrrolidone, 67 parts of polyurethane resin, 4.7 parts of liquid nitrile rubber, 9.5 parts of polyethylene glycol, 4.1 parts of sodium acetate trihydrate, 9.9 parts of sodium citrate, 33.5 parts of acrylic acid, persulfuric acid 0.7 parts of ammonium, 0.7 parts of methyl ethyl ketone peroxide, 0.1 parts of cobalt naphthenate, 39 parts of ethyl acetate, 0.8 parts of succinic anhydride, and 7 parts of flake graphite.

[0023] A wear-resistant, corrosion-resistant, and heat-resistant high-performance magnetic plastic door valve sealing material, the preparation method of which comprises the following steps: 1. Weig...

Embodiment 2

[0029] A wear-resistant, corrosion-resistant and heat-resistant high-performance magnetic plastic door valve sealing material is prepared from the following raw materials in parts by weight: 33.5 parts of ferric chloride hexahydrate, 35 parts of ethylene glycol, 3.4 parts of modified hyperbranched polyester, ethylene 117 parts of base ester resin, 8.3 parts of polyvinylpyrrolidone, 57 parts of polyurethane resin, 4.7 parts of liquid nitrile rubber, 9.5 parts of polyethylene glycol, 2.3 parts of sodium acetate trihydrate, 8.1 parts of sodium citrate, 21.5 parts of acrylic acid, persulfuric acid 0.5 parts of ammonium, 0.7 parts of methyl ethyl ketone peroxide, 0.1 parts of cobalt naphthenate, 30 parts of ethyl acetate, 0.8 parts of succinic anhydride, and 7 parts of flake graphite.

[0030] A wear-resistant, corrosion-resistant, and heat-resistant high-performance magnetic plastic door valve sealing material, the preparation method of which comprises the following steps: 1. Weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com