High speed railway bridge bearing anchoring mortar material

A bridge support and mortar material technology, applied in the field of building materials, can solve the problems of insufficient one-day flexural strength, poor perfusion filling performance, and insufficient hourly strength, etc., to achieve improved appearance, improved flow performance, and simple use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

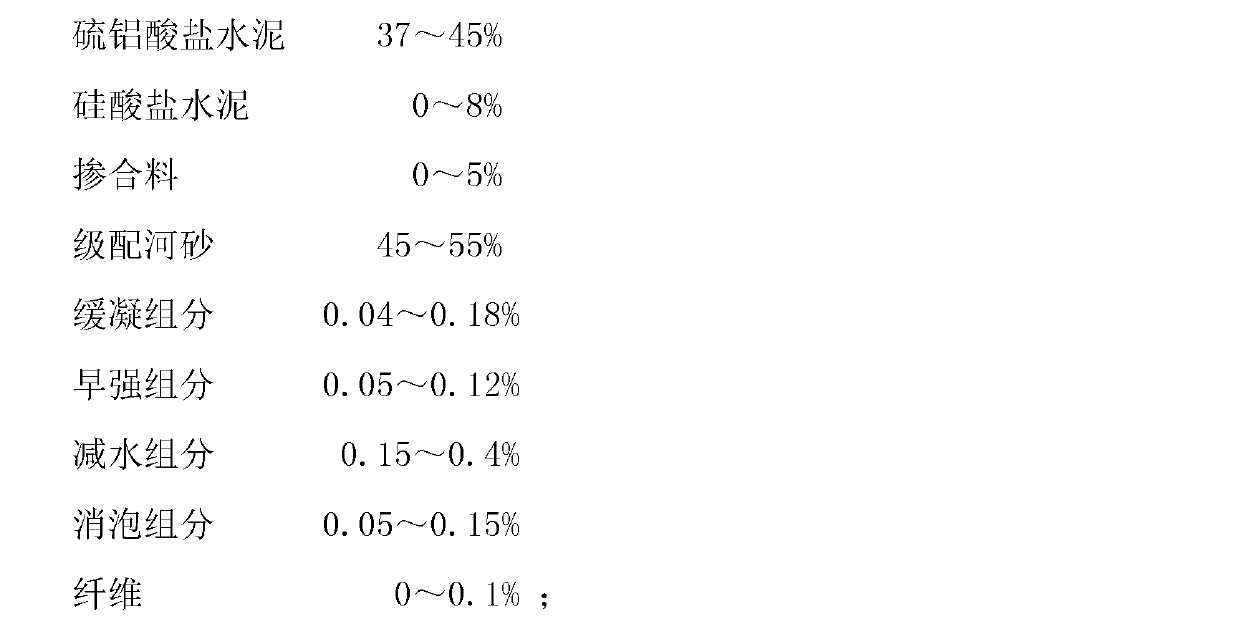

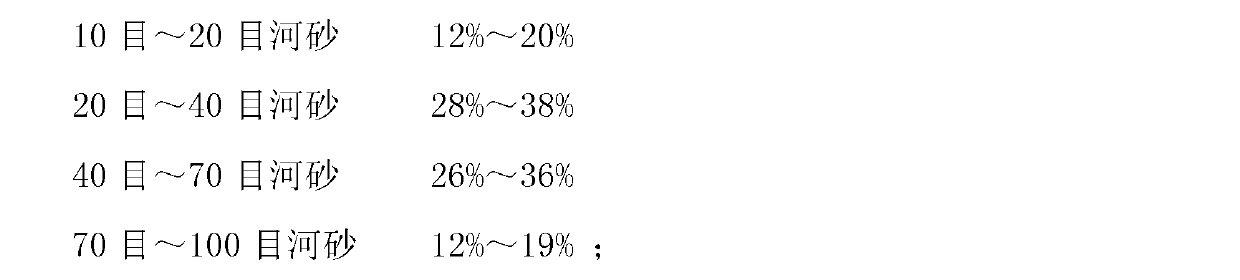

[0032]

[0033] Wherein, the admixture is an equal mass mixture of silica fume and fly ash, the retarding component is a mixture of sodium gluconate and boric acid, the mass ratio of the two is sodium gluconate: boric acid=1: 1, and the early strength component It is a mixture of aluminum sulfate and lithium carbonate, and the mass ratio of the two is aluminum sulfate: lithium carbonate=1:1.

[0034] Fully automatic production equipment for dry powder mortar is adopted to automatically weigh each raw material component according to the mix ratio, automatically feed materials, automatically stir evenly, and automatically package them into products.

Embodiment 2

[0036]

[0037] Fully automatic production equipment for dry powder mortar is adopted to automatically weigh each raw material component according to the mix ratio, automatically feed materials, automatically stir evenly, and automatically package them into products.

Embodiment 3

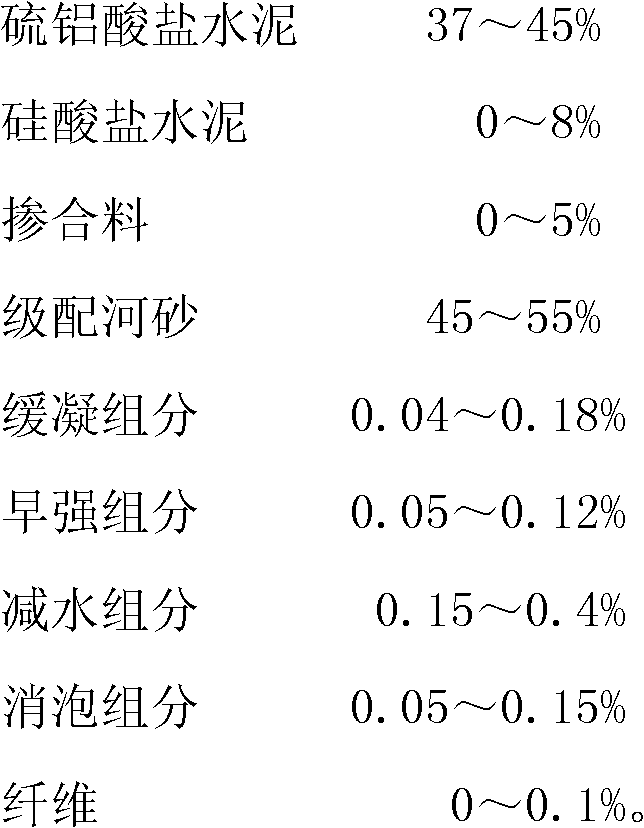

[0039]

[0040] Wherein, retarding component is the mixture of sodium gluconate and citric acid, and the mass ratio of the two is sodium gluconate: citric acid=1: 1, and early strength component is the mixture of sodium sulfate and lithium carbonate, the mass ratio of the two The ratio is sodium sulfate: lithium carbonate = 1:2.

[0041] Fully automatic production equipment for dry powder mortar is adopted to automatically weigh each raw material component according to the mix ratio, automatically feed materials, automatically stir evenly, and automatically package them into products.

[0042] The product performance results of each embodiment are as follows:

[0043]

[0044]

[0045] According to the product properties of the three formulations measured in the table, the properties of the three examples of the mortar can all meet the anchoring mortar materials proposed in the Kejiji [2005] No. 101 document "Temporary Technical Conditions for Basin Rubber Bearings of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com