Method for extracting and refining clopyralid

A technology for clopyralid acid and clopyralid acid mother is applied in the field of extraction and purification of clopyralid acid, which can solve the problem of high energy consumption of the clopyralid acid technology, and achieve the advantages of fully recovering effective components, good quality and simplifying traditional processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

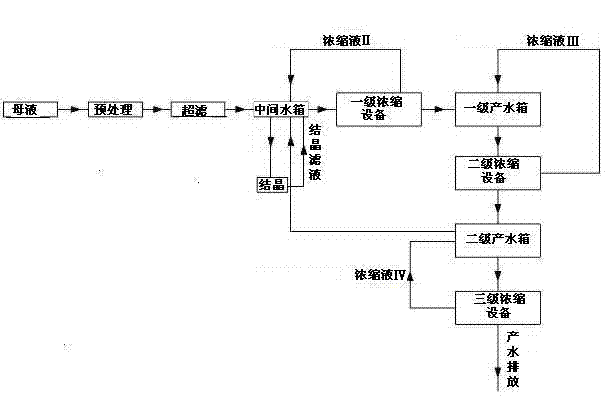

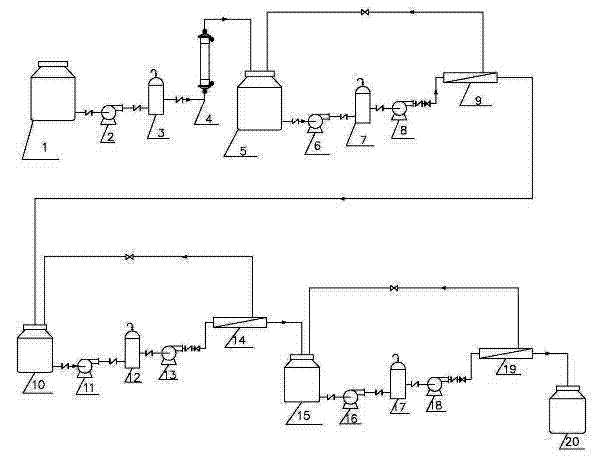

[0034] combine figure 1 with figure 2 , a method for extracting and refining clopyralid:

[0035] By booster pump 2, the mother liquor of clopyralid (content 4.8%) (COD cr=25000mg / L) into the 10μm bag filter 3, and then into the ultrafiltration device 4, the operating pressure is 0.10Mpa, the recovery rate is controlled at 90%, and the ultrafiltration membrane (molecular weight cut-off is 150,000 Daltons) The concentrated liquid I after impurity removal is mixed with the mother liquor of clopyralid for reuse, and the permeate liquid I (turbidity cr =7000mg / L), the permeate III is sent to the secondary product water tank 15; the feed liquid (permeate III) of the secondary product water tank is transported to the three-stage concentration equipment 19 by the high-pressure pump 18, and passes through the three-stage concentration membrane (using Roll-type composite membrane, with a desalination rate of over 95%), the concentrated solution IV obtained after treatment is returne...

Embodiment 2

[0037] combine figure 1 with figure 2 , a method for extracting and refining clopyralid:

[0038] By booster pump 2, the mother liquor of clopyralid (content 3.5%) (COD cr =28000mg / L) into the 10μm bag filter 3, and then into the ultrafiltration device 4, the operating pressure is 0.12Mpa, the recovery rate is controlled at 95%, and the ultrafiltration membrane (molecular weight cut-off is 50,000 Daltons) The concentrated liquid I after impurity removal is mixed with the mother liquor of clopyralid for reuse, and the permeate liquid I (turbidity cr =7500mg / L), the permeate III is sent to the secondary product water tank 15; the feed liquid (permeate III) of the secondary product water tank is transported to the three-stage concentration equipment 19 by the high-pressure pump 18, and passes through the three-stage concentration membrane (using Roll-type composite membrane, with a desalination rate of over 95%), the concentrated liquid IV obtained after treatment is returned ...

Embodiment 3

[0040] combine figure 1 with figure 2 , a method for extracting and refining clopyralid:

[0041] By booster pump 2, the mother liquor of clopyralid (content 5.5%) (COD cr =30000mg / L) into the 10μm bag filter 3, and then into the ultrafiltration device 4, the operating pressure is 0.25Mpa, the recovery rate is controlled at 95%, and the ultrafiltration membrane (molecular weight cut-off is 100,000 Daltons) The concentrated liquid Ⅰ after impurity removal is mixed with the mother liquor of clopyralid for reuse, and the permeate liquid Ⅰ (turbidity cr =7800mg / L), the permeate III is sent to the secondary product water tank 15; the feed liquid (permeate III) of the secondary product water tank is transported to the third-stage concentration equipment 19 by the high-pressure pump 18, and passes through the three-stage concentration membrane (using Roll-type composite membrane, with a desalination rate of over 95%), the concentrated liquid IV obtained by the treatment is returne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com