Intelligent reducing self-starting vertical axis wind power generation device

A wind power generation device, vertical axis technology, applied in the direction of wind turbines, wind turbines, wind motor combinations, etc. at right angles to the wind direction, can solve problems such as difficulty in starting, unfavorable long-term stable operation of wind turbines, and complex wind turbine mechanisms, and achieve Strong scalability, easy remote automatic control, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

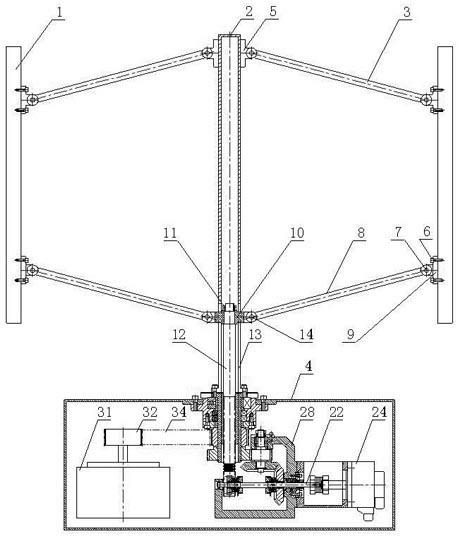

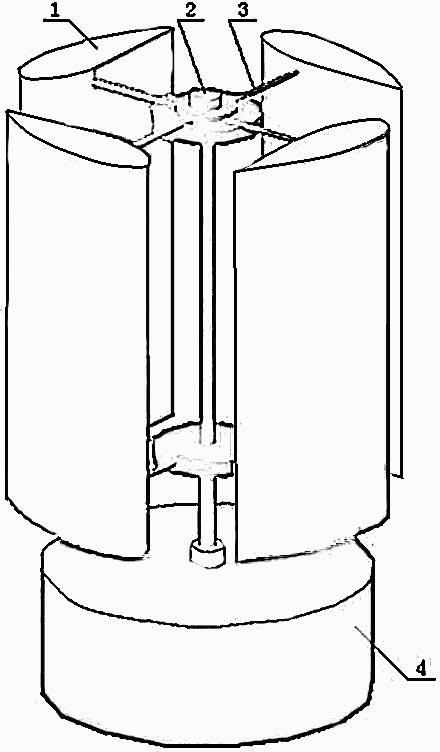

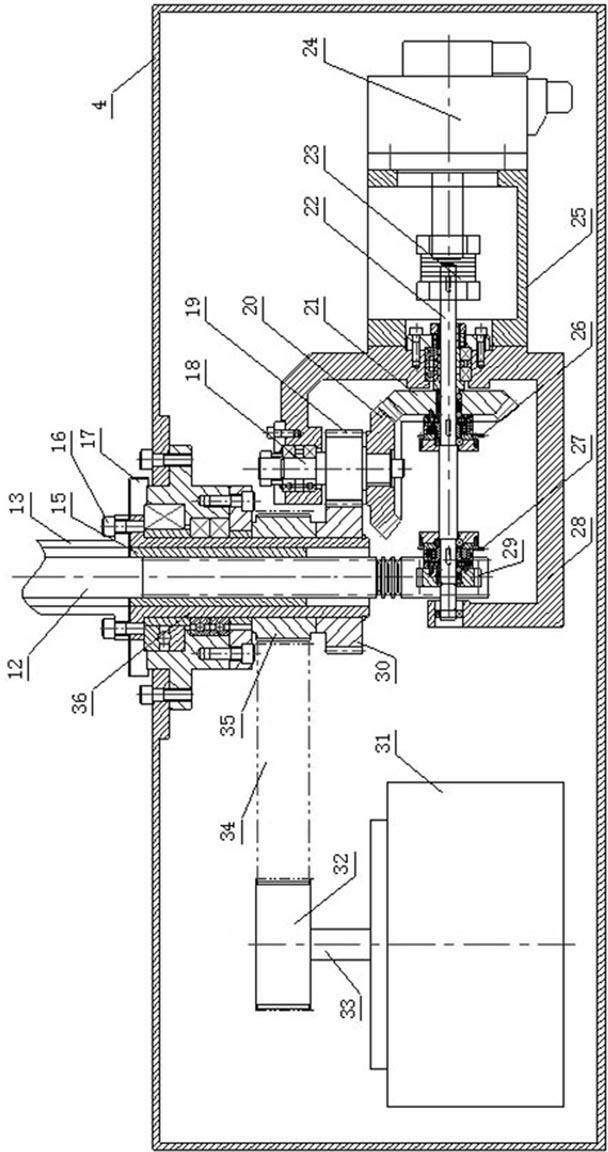

[0042] Such as Figure 1-3 An intelligent variable-diameter self-starting vertical-axis wind power generation device shown includes: wind rotor blade 1, wind rotor main shaft 2, upper variable-diameter rod 3, base 4, fixed hinge seat 5, bolt 6, hinge 7, lower transformer Diameter rod 8, variable diameter hinge seat 9, variable diameter connecting seat 10, nut 11, variable diameter rack shaft 12, wind wheel main shaft vertical groove 13, hinge 14, sliding bearing 15, bolt 16, protective cover 17, gear shaft 18. The first straight gear 19, the vertical axis bevel gear 20, the horizontal axis bevel gear 21, the main transmission shaft 22, the coupling 23, the servo motor 24, the motor connection seat 25, the electromagnetic clutch 26 of the self-starting mechanism, the electromagnetic clutch of the reducing mechanism Clutch 27, gear case 28, second spur gear 29, third spur gear 30, generator 31, driven pulley 32, generator transmission shaft 33, synchronous belt 34, driving pulle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com