Capacitance micro-machining ultrasonic sensor for measuring density and production method thereof

An ultrasonic sensor and density measurement technology, which is applied in the field of MEMS technology and liquid physical parameter testing, can solve the problems of low sensitivity and large sensor volume, and achieve stress matching, reliability and accuracy, reliability and The effect of measurement precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

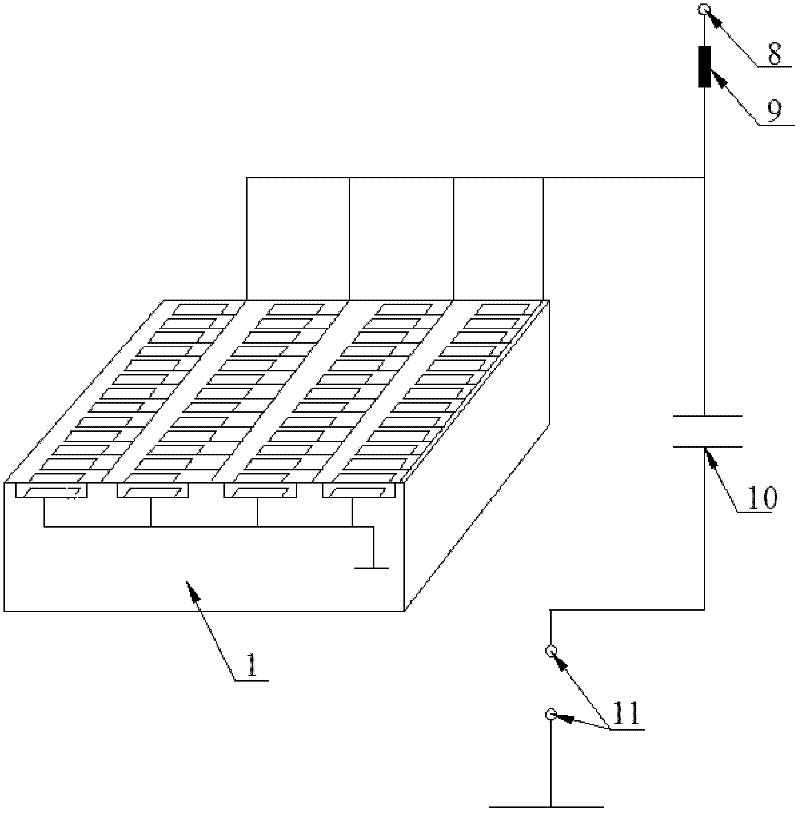

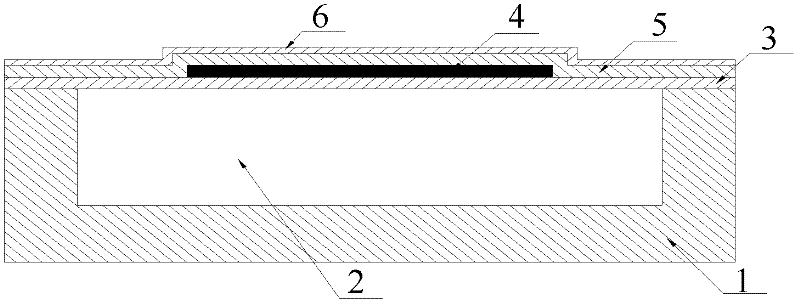

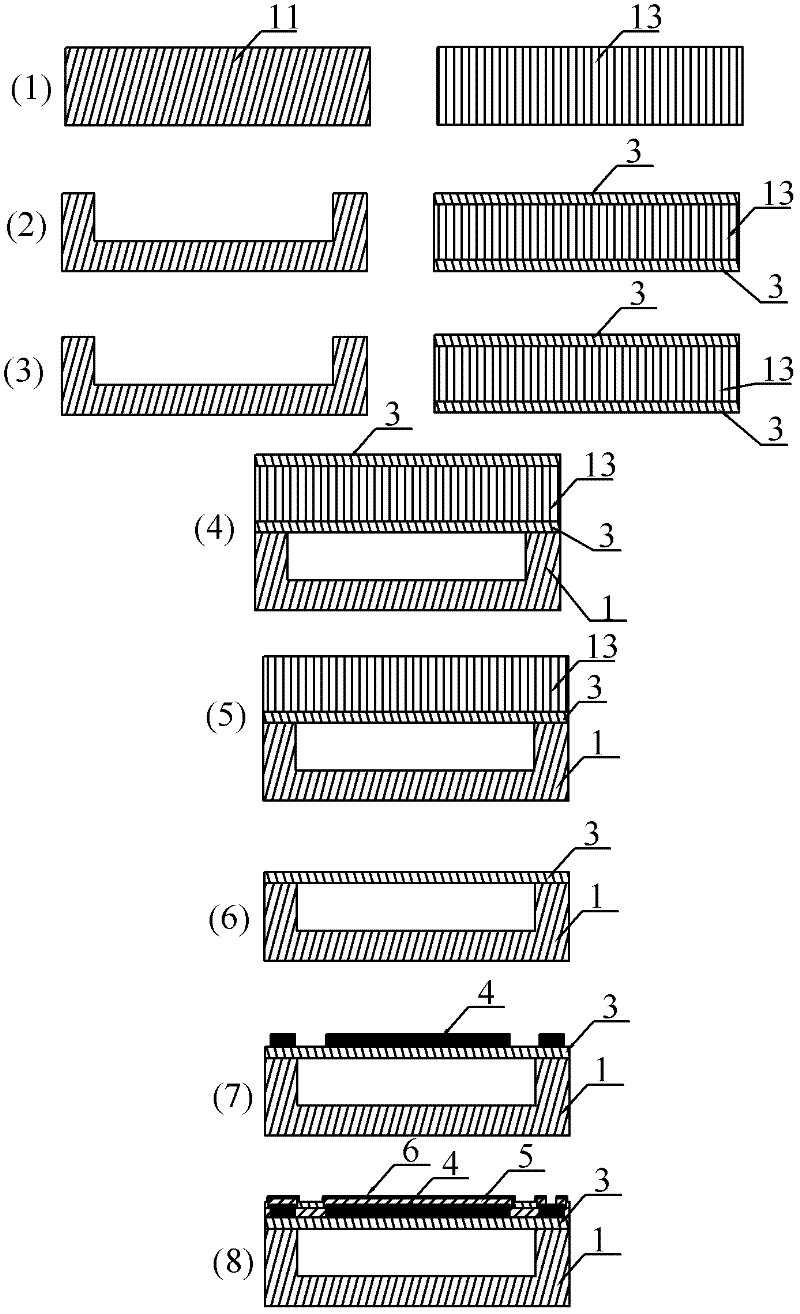

[0017] The capacitive microfabricated ultrasonic transducer (CMUT) and its preparation method for density measurement of the present invention are described in detail below in conjunction with the accompanying drawings:

[0018] The capacitive micromachining ultrasonic density sensor of the present invention is used to measure the density of fluid, realizes micro-measurement, satisfies on-line measurement, and has the advantages of short measurement time, high precision, good working stability and high reliability. The sensor includes a CMUT array unit, which sequentially includes a silicon dioxide stress matching layer 6, a silicon nitride insulating layer 5, a metal electrode 4, a silicon dioxide film 3 and a single crystal silicon substrate 1 from top to bottom, wherein , the metal electrode 4 is the upper electrode, the single crystal silicon substrate 1 is the lower electrode, the single crystal silicon substrate is provided with a cavity 2, the silicon dioxide film 3 seal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com