Method for preparing cellulose spinning stock solution

A technology for spinning dope and cellulose, which is used in fiber processing, spinning solution preparation, textiles and papermaking, etc., can solve the problems of unavailability and pollution of twin-screw extruders, improve fluidity, strengthen dissolution effect, Beneficial effects on stretching and molecular orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

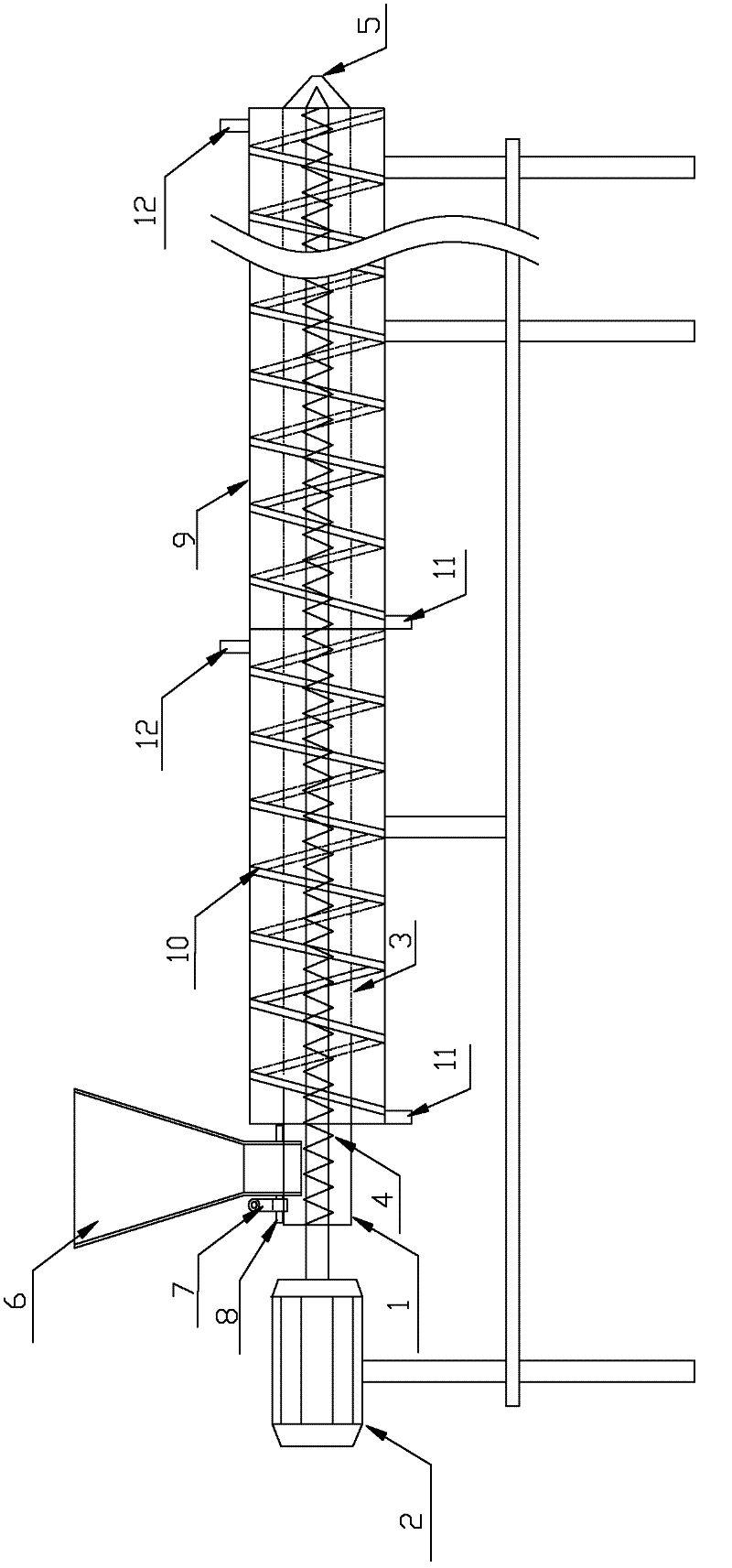

Image

Examples

Embodiment 1

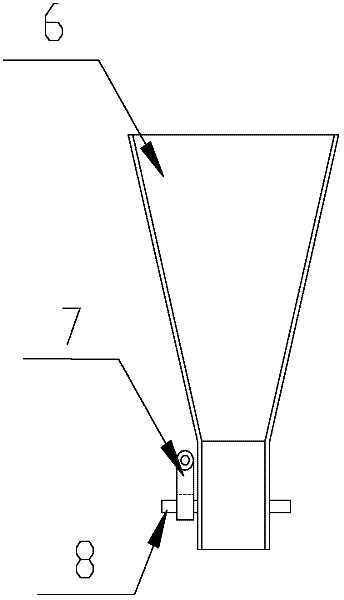

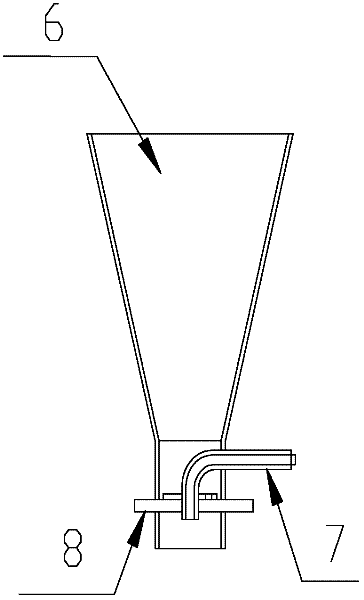

[0070] A 7wt% NaOH / 11wt% urea mixed aqueous solution was prepared, cooled to -10°C, and kept at a constant temperature. Then feed it into the feed port of the twin-screw extruder at a flow rate of 29.1kg / h, and feed the wood pulp with a degree of polymerization of 450 into the feed port of the twin-screw extruder at a feed rate of 0.9kg / h , so that once in contact with the solvent it is fed into the interior of the twin-screw extruder by the rotating helical elements.

[0071] The speed of the twin-screw extruder is 120rpm, the temperature of the front 3 / 5 length is -10°C, the temperature of the middle 1 / 5 length is 0°C, and the temperature of the rear 1 / 5 length is 25°C, and the temperature fluctuation of each section is controlled within ±1°C within range.

[0072] The discharge port of the twin-screw extruder is connected to the feed port of the wiped film thin film evaporator through a pipeline, and the material flow rate and the head pressure of the twin-screw extruder a...

Embodiment 2

[0075] Prepare the solvent according to the ratio of Example 1, cool it to -12°C, and keep it at a constant temperature. Then feed it into the feed port of the twin-screw extruder at a flow rate of 28.2kg / h, and feed the wood pulp with a degree of polymerization of 450 into the feed port of the twin-screw extruder at a feed rate of 1.8kg / h , so that they are fed into the interior of the twin-screw extruder by the rotating screw elements as soon as they come into contact with each other.

[0076] The speed of the twin-screw extruder is 200rpm, the temperature of the front 4 / 5 length is -10°C, the temperature of the rear 1 / 5 length is 0°C, and the temperature fluctuation of each section is controlled within the range of ±1°C.

[0077] The discharge port of the twin-screw extruder is connected to the feed port of the wiped film thin film evaporator through a pipeline, and the material flow rate and the head pressure of the twin-screw extruder are controlled by a metering pump in ...

Embodiment 3

[0080] Prepare the solvent according to the ratio of Example 1, cool it to -12.5°C, and keep it at a constant temperature. Then feed it into the feed port of the twin-screw extruder at a flow rate of 27.6kg / h, and simultaneously feed the wood pulp with a degree of polymerization of 450 into the feed port of the twin-screw extruder at a feed rate of 2.4kg / h , so that they are fed into the interior of the twin-screw extruder by the rotating screw elements as soon as they come into contact with each other.

[0081] The rotational speed of the twin-screw extruder is 300rpm, the temperature of the twin-screw extruder is all -10°C, and the temperature fluctuation of each section is controlled within the range of ±1°C.

[0082] The discharge port of the twin-screw extruder is connected to the feed port of the wiped film thin film evaporator through a pipeline, and the material flow rate and the head pressure of the twin-screw extruder are controlled by a valve or a gear metering pump...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| aggregation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com