Optical film with raster

An optical film and grating technology, applied in the field of optical film, can solve the problems of high cost, complex LED drive circuit, uneven chromaticity, etc., and achieve the effect of increasing interaction distance, reducing serious loss of blue light, and improving the brightness of the central wavelength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

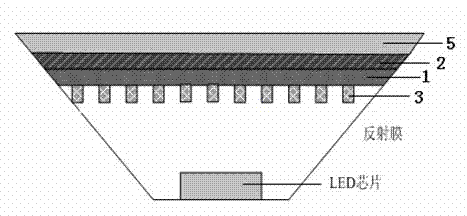

[0022] Please see first figure 1 , figure 1 It is the first embodiment of the optical film with grating in the present invention, and it is also a white light LED composed of the optical film with grating. As shown in the figure, the LED chip is placed in a bowl-shaped support frame with a reflective film around it, and the optical film with a grating of the present invention is placed at the outlet of the bowl, including a substrate 1, which is transparent plastic or glass. The side of the substrate 1 close to the LED light source has a grating 3 , and the other side of the substrate 1 is coated with a fluorescent film 2 . The light-emitting surface of the fluorescent film 2 also has a protective film 5 with some diffusion structures on the protective film.

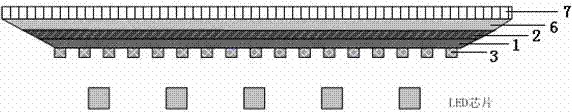

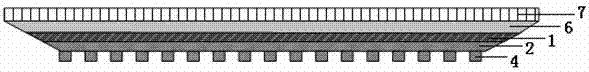

[0023] figure 2 It is the second embodiment of the optical film with grating in the present invention, and it is also a white light illumination backlight system composed of the optical film with grating. As shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com