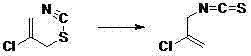

Method for preparing 2-chloro-3-isothiocyanato-prop-1-ene

A technology of chloroallyl isothiocyanate and sodium thiocyanate, which is applied in the field of preparation of precursor 2-chloroallyl isothiocyanate, can solve the problems of cumbersome operation and low yield, and achieve Simplify the operation process, improve the yield and reduce the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Dissolve 97g of sodium thiocyanide, 0.5g of tetrabutylammonium chloride and 1g of potassium iodide in 600mL of water, add 111g of 2,3-dichloropropene, stir at 90°C for 20h, and detect the nucleophilicity of 2,3-dichloropropene by gas chromatography The substitution has been completely completed, and the rearrangement process has also been completed. At this time, the ratio of the rearrangement product to the substitution product in the system is 30:1. The reaction system is cooled to room temperature and left to stand. The system is in two phases, and the organic phase is separated out. The phase is bright yellow and transparent, and the organic phase is distilled under reduced pressure at a pressure of 40 mmHg, and the cuts at a temperature of 115 to 125 ° C are collected to obtain 122 g of 2-chloroallyl isothiocyanate in the form of a colorless transparent liquid. The total yield of the two steps of substitution reaction and rearrangement reaction is 91%. After the di...

Embodiment 2

[0029] Dissolve 97g of sodium thiocyanide and 1g of tetrabutylammonium chloride in 600mL of water, add 111g of 2,3-dichloropropene, stir at 90°C for 10 hours, gas chromatography detects that there is an obvious residue of 2,3-dichloropropene, continue heating and stirring To 24h, there is still a small amount of 2,3-dichloropropene, and the organic phase is cooled and separated. At this time, the organic phase is dark brown, and a small amount of 2,3-dichloropropene is removed by fractional distillation under reduced pressure. For product, 115-125 / 40mmHg, obtain 109g of colorless transparent liquid, yield 81%, after distillation finishes, there is a large amount of bitumen-like still bottom material residue, adds organic solvent and also is difficult to dissolve.

Embodiment 3

[0031] Dissolve 97g of sodium thiocyanide and 1g of potassium iodide in 600mL of water, add 111g of 2,3-dichloropropene, stir at 90°C for 24 hours, and detect by gas chromatography that 2,3-dichloropropene is obviously left.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com