Heat-transfer medium specially used for solar energy heat pump

A technology of solar heat pump and heat transfer medium, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of high energy consumption, slow heat transfer, and low thermal efficiency of heat transfer media, and achieve less evaporation loss and low freezing point , good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

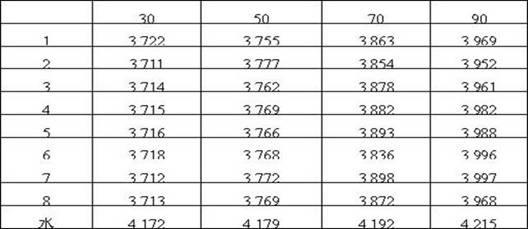

[0023] According to the components shown in Table 1 (distilled water is the balance), No. 1-8 heat transfer medium was prepared according to the preparation method disclosed in the present invention.

[0024] Table 1 Composition of heat transfer medium (unit: wt%, balance is distilled water)

[0025] Numbering calcium chloride sodium perborate sodium nitrate Potassium borate sodium benzoate Benzotriazole Absolute ethanol 1 0.15 0.5 0.3 0.8 0.20 0.2 0.5 2 0.27 0.6 0.5 1.0 0.27 0.4 0.7 3 0.35 0.7 0.7 1.2 0.35 0.6 0.8 4 0.40 0.8 0.8 1.5 0.40 0.8 0.9 5 0.47 0.9 0.9 1.8 0.47 0.9 1.0 6 0.55 1.0 1.0 2.0 0.55 1.0 1.2 7 0.60 1.1 1.1 2.3 0.65 1.1 1.5 8 0.65 1.2 1.2 2.5 0.75 1.2 1.75

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com