Easily-dispersible powder, the surface of which has undergone lipophilization treatment, and cosmetic blended therewith

A technology of surface treatment and surface treatment agent, applied in the field of lipophilic surface treatment powder, can solve problems such as poor dispersibility, and achieve the effect of good makeup durability and excellent characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

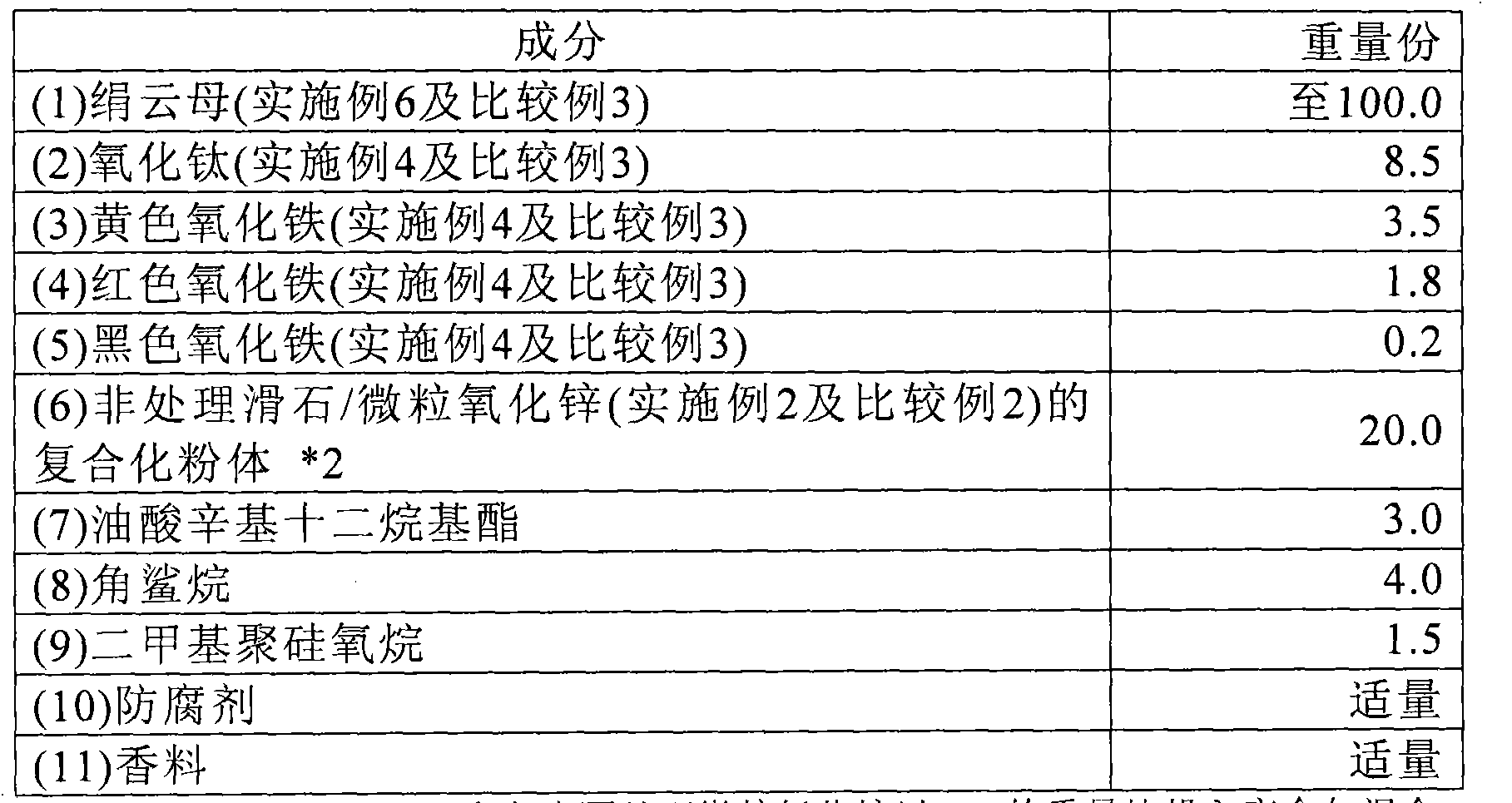

Examples

Embodiment 1

[0059] 2 kg of microparticle titanium oxide (manufactured by Ishihara Sangyo Co., Ltd.: TTO-S-3) was put into a Henschel mixer, and octyltriethoxysilane (Toray Dow Corning Co., Ltd. (Toray Dow Corning Co., Ltd.: Z-6341) 300 g and a liquid mixture of reactive organosiloxane (Shin-Etsu Chemical Co., Ltd.: X-24-9171) 60 g were stirred for 30 minutes. Then, after pulverizing with a jet mill (manufactured by Alpine (Germany): 100AFG type) with a crushing pressure of 4 kg and a classification speed of 10,000 rpm, it was dried at 110° C. for 9 hours with a hot air dryer to obtain lipophilicity. Surface treatment powder.

Embodiment 2

[0061] The lipophilic surface-treated powder was obtained under the same production conditions as in Example 1, except that fine-grained zinc oxide (manufactured by Imperial Chemicals (Tayca): MZ-500) was used instead of the fine-grained titanium oxide in Example 1.

Embodiment 3

[0063] Put 100 g of microparticle titanium oxide (manufactured by Imperial Chemical Industry Co., Ltd.: MT-500SA) into 1500 ml of a mixed solution of deionized water / IPA=50 / 50, and add hexyltriethoxysilane (manufactured by Shin-Etsu Chemical Co., Ltd.: KBE-3063) 8g and isohexadecanoic acid 6g, with a sand mill (DYNO-Mill: 1.4L zirconia container & blade, filling rate of 0.5mmφ zirconia beads 85%) by 30 minutes circulation To disperse. The dispersion liquid was dried under reduced pressure at 100° C. for 7 hours with a vacuum dryer, and then pulverized with a jet mill at a crushing pressure of 5 kg and a classification rotation speed of 10,000 rpm to obtain a lipophilic surface-treated powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com