Catalyst for preparing aromatic hydrocarbons by methanol conversion and preparation method thereof

A methanol conversion and catalyst technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of low selectivity of target product aromatics and complex process routes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

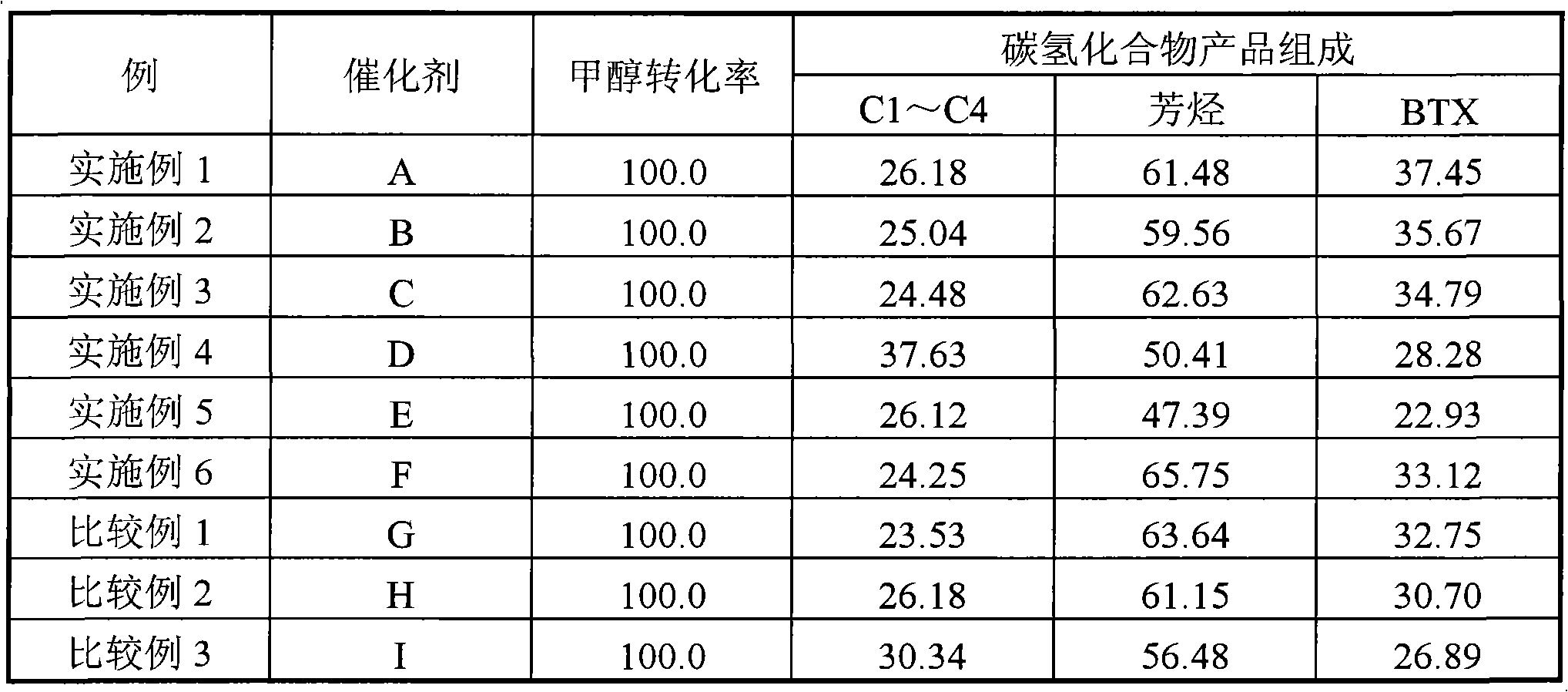

Examples

Embodiment 1

[0013] The preparation of this embodiment includes: based on the total weight of the catalyst, 3% La 2 o 3 , 5% Ga 2 o 3 , 55% HZSM-5, 17% HMCM-22, 20% Al 2 o 3 Catalyst A.

[0014] Weigh 55 grams of HZSM-5 molecular sieve, 17 grams of HMCM-22 molecular sieve, 20 grams of Al 2 o 3 , 3.6 grams of scallop powder, mix it uniformly, add 40 grams of mass concentration of 5% nitric acid aqueous solution, fully knead and extrude into a cylindrical shape with a diameter of 1.5 mm, dry and roast at 600 ° C for 4 hours to make 2 ~ 3 mm long catalyst support.

[0015] 20 g of the above catalyst carrier was impregnated in 14 ml containing 1.09 g of Ga 2 o 3 In the gallium nitrate aqueous solution, the catalyst intermediate was prepared after standing at room temperature for 24 hours, drying, and calcining at 450°C for 6 hours.

[0016] The above catalyst intermediate was impregnated in 14 ml containing 0.65 g La 2 o 3 In the lanthanum nitrate aqueous solution, the catalyst A w...

Embodiment 2

[0019] The preparation of this embodiment includes: based on the total weight of the catalyst, 2% P 2 o 5 , 3% Ga 2 o 3 , 40% HZSM-5, 25% HMCM-22, 30% Al 2 o 3 Catalyst B.

[0020] Weigh 40 grams of HZSM-5 molecular sieve, 25 grams of HMCM-22 molecular sieve, 30 grams of Al 2 o 3 , 3.8 grams of scallop powder, mixed evenly, adding 40 grams of nitric acid aqueous solution with a mass concentration of 5%, fully kneaded and extruded into a cylindrical shape with a diameter of 1.5 mm, dried and roasted at 520 ° C for 4 hours to make 2 ~ 3 mm long catalyst support.

[0021] 20 g of the above catalyst carrier was impregnated in 14 ml containing 0.63 g of Ga 2 o 3 In the gallium nitrate aqueous solution, the catalyst intermediate was prepared after standing at room temperature for 24 hours, drying, and calcining at 480°C for 4 hours.

[0022] The above catalyst intermediate was impregnated in 14 ml containing 0.42 g P 2 o 5 In the ammonium dihydrogen phosphate aqueous sol...

Embodiment 3

[0025] The preparation of this embodiment includes: based on the total weight of the catalyst, 5% La 2 o 3 , 8% Ga 2 o 3 , 20% HZSM-5, 40% HMCM-22, 27% Al 2 o 3 Catalyst C.

[0026] Weigh 20 grams of HZSM-5 molecular sieve, 40 grams of HMCM-22 molecular sieve, 27 grams of Al 2 o 3 , 3.5 grams of scallop powder, mixed evenly, adding 40 grams of nitric acid aqueous solution with a mass concentration of 5%, fully kneaded and extruded into a cylindrical shape with a diameter of 1.5 mm, dried and roasted at 550 ° C for 4 hours to make 2 ~ 3 mm long catalyst support.

[0027] 20 g of the above catalyst carrier was impregnated in 14 ml containing 1.84 g of Ga 2 o 3 In the gallium nitrate aqueous solution, the catalyst intermediate was prepared after standing at room temperature for 24 hours, drying, and calcination at 500°C for 4 hours.

[0028] The above catalyst intermediate was impregnated in 14 ml containing 1.15 g La 2 o 3 In the lanthanum nitrate aqueous solution, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com