Method for preparing copper/molybdenum/copper layered compound metallic material

A composite metal material, copper layer technology, applied in metal processing equipment, metal layered products, chemical instruments and methods, etc. Alloy and other problems, to achieve the effect of low equipment requirements, low production cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of copper / molybdenum / copper layered composite metal material with a thickness of 0.3mm: 0.5mm: 0.3mm:

[0037] Step 1. Grind the surface to be compounded of copper plate 1 and copper plate 2 with sandpaper until the surface roughness is not greater than 1.6 μm, and polish the surface to be compounded of molybdenum plate 2 with a grinding wheel until the surface roughness is not greater than 1.6 μm Wipe the surface to be compounded of the polished copper plate 1, copper plate 2 3 and molybdenum plate 2 with alcohol; the grades of the copper plate 1 and copper plate 2 3 are both T2, and the specifications are 2mm × 110mm × 180mm. The grade of the molybdenum plate 2 is Mo1, and the specification is 2mm×100mm×150mm;

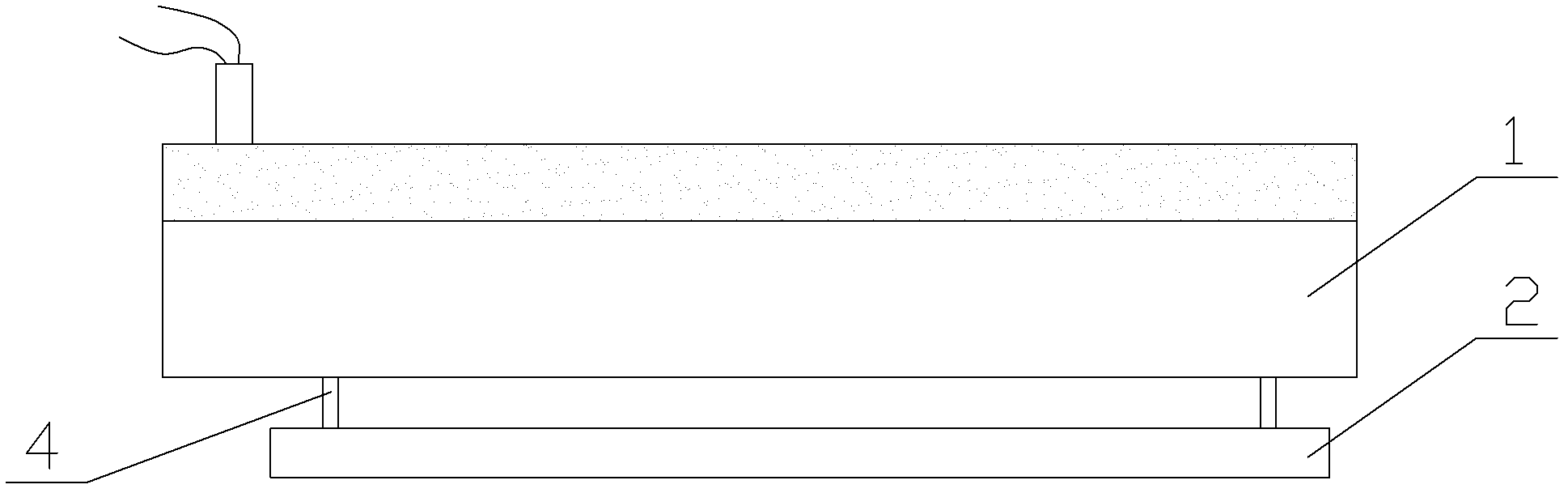

[0038] Step two, such as figure 1 As shown, place the molybdenum plate 2 wiped clean in step 1 on a rigid foundation, and then evenly arrange two gap materials-4 with a height of 5mm above the molybdenum plate 2, and then place the copper plate-1 ...

Embodiment 2

[0045] Preparation of copper / molybdenum / copper layered composite metal material with a thickness of 0.2mm: 0.7mm: 0.2mm:

[0046] Step 1. Grind the surface to be compounded of copper plate 1 and copper plate 2 with sandpaper until the surface roughness is not greater than 1.6 μm, and polish the surface to be compounded of molybdenum plate 2 with a grinding wheel until the surface roughness is not greater than 1.6 μm Wipe the surface to be compounded of the polished copper plate 1, copper plate 2 3 and molybdenum plate 2 with alcohol; the grades of the copper plate 1 and copper plate 2 3 are both T2, and the specifications are 2mm × 160mm × 230mm, The grade of described molybdenum plate 2 is Mo1, and specification is 3mm * 150mm * 200mm;

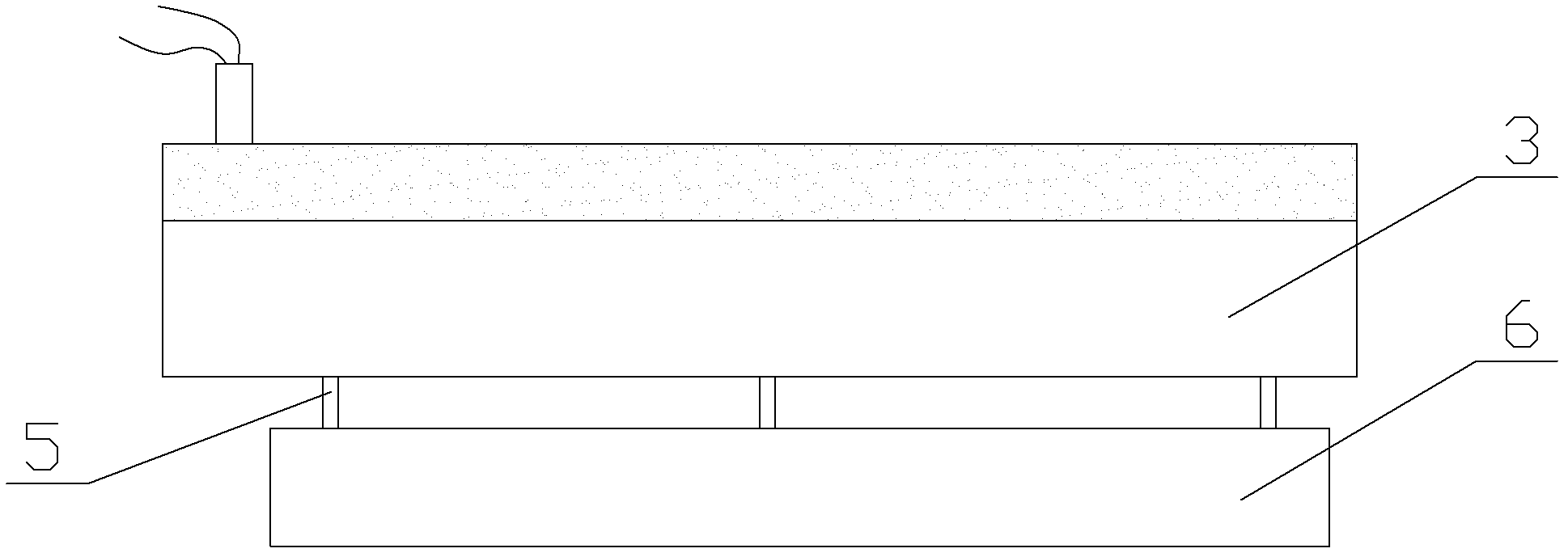

[0047] Step 2. Place the molybdenum plate 2 wiped clean in step 1 on the rigid foundation, and then evenly set three gap material-4 with a height of 1mm above the molybdenum plate 2, and then place the copper plate-1 above the gap material-4 ...

Embodiment 3

[0054] Preparation of copper / molybdenum / copper layered composite metal material with a thickness of 0.3mm: 0.2mm: 0.3mm:

[0055] Step 1. Grind the surface to be compounded of copper plate 1 and copper plate 2 with sandpaper until the surface roughness is not greater than 1.6 μm, and polish the surface to be compounded of molybdenum plate 2 with a grinding wheel until the surface roughness is not greater than 1.6 μm Wipe the surface to be compounded of the polished copper plate 1, copper plate 2 3 and molybdenum plate 2 with alcohol; the grades of the copper plate 1 and copper plate 2 3 are both T2, and the specifications are 1mm × 110mm × 180mm, The grade of molybdenum plate 2 is Mo1, and the specification is 0.5mm×100mm×150mm;

[0056] Step 2. Place the molybdenum plate 2 wiped clean in step 1 on the rigid foundation, then evenly set 4 gap material 4 with a height of 3mm above the molybdenum plate 2, and then place the copper plate 1 above the gap material 4 , and keep the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com