Method for preparing tetramethylethylene through isobutene metathesis

A technology of tetramethylethylene and isobutylene, applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc., can solve the problems of low yield of tetramethylethylene, low catalyst activity, low reaction space velocity, etc. The effect of increasing the rate, increasing the specific surface area, and improving the disproportionation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

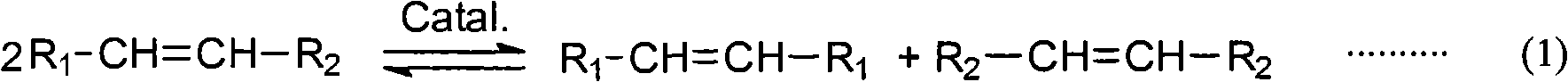

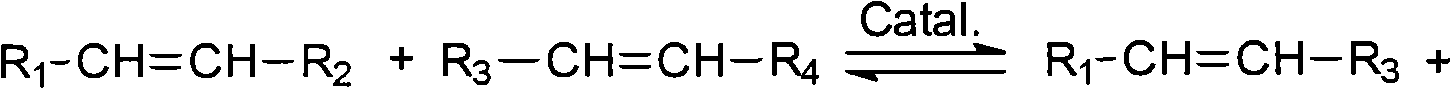

Problems solved by technology

Method used

Image

Examples

Embodiment 1

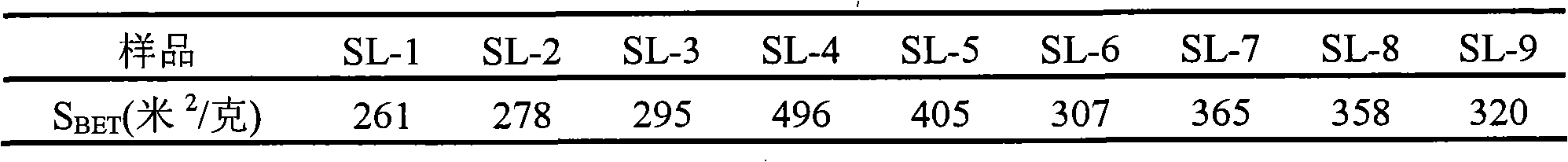

[0022] Add 1 kg of 700-mesh chromatographic silica gel and 10 g of scallop powder into the mixer and stir for 45 minutes. After kneading evenly, add 400 g of silica sol and 63 g of ammonium metatungstate, and add 1 kg of deionized water at the same time, knead and extrude , dried, and then calcined at 550° C. for 4 hours to obtain a light yellow finished catalyst with a content of 5% tungsten oxide. The evaluation of the catalyst was carried out on an olefin disproportionation evaluation device, and the raw material was 99.9% isobutene. The reaction is at a temperature of 385 °C, a pressure of 0.5 MPa, and a space velocity of butene-1 of 4 hours -1 The evaluation is carried out under the condition of the above, and the evaluation results are shown in Table 2, which is recorded as SL-1.

Embodiment 2

[0024] According to each step in embodiment 1, only change the ammonium metatungstate to be 113 grams, the loading capacity of the catalyst tungsten oxide that makes is 8%, change the reaction temperature in the reaction condition to be 350 ℃, reaction pressure be 0.2MPa and space velocity for 1 hour -1 , the evaluation results are shown in Table 2, recorded as SL-2.

Embodiment 3

[0026] According to each step in embodiment 1, only change the ammonium metatungstate to be 163 grams, the loading capacity of the prepared catalyst tungsten oxide is 12%, change the reaction temperature in the reaction conditions to be 370 ℃, the reaction pressure to be 0.4MPa and the space velocity for 2 hours -1 , the evaluation results are shown in Table 1, recorded as SL-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com