Method for manufacturing amino acid liquid fertilizer using livestock blood and amino acid liquid fertilizer manufactured thereby

A liquid fertilizer and amino acid technology, applied in liquid fertilizer, animal carcass fertilizer, organic fertilizer, etc., can solve problems such as damage, achieve the effects of preventing environmental pollution, simplifying the preparation process, and reducing preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

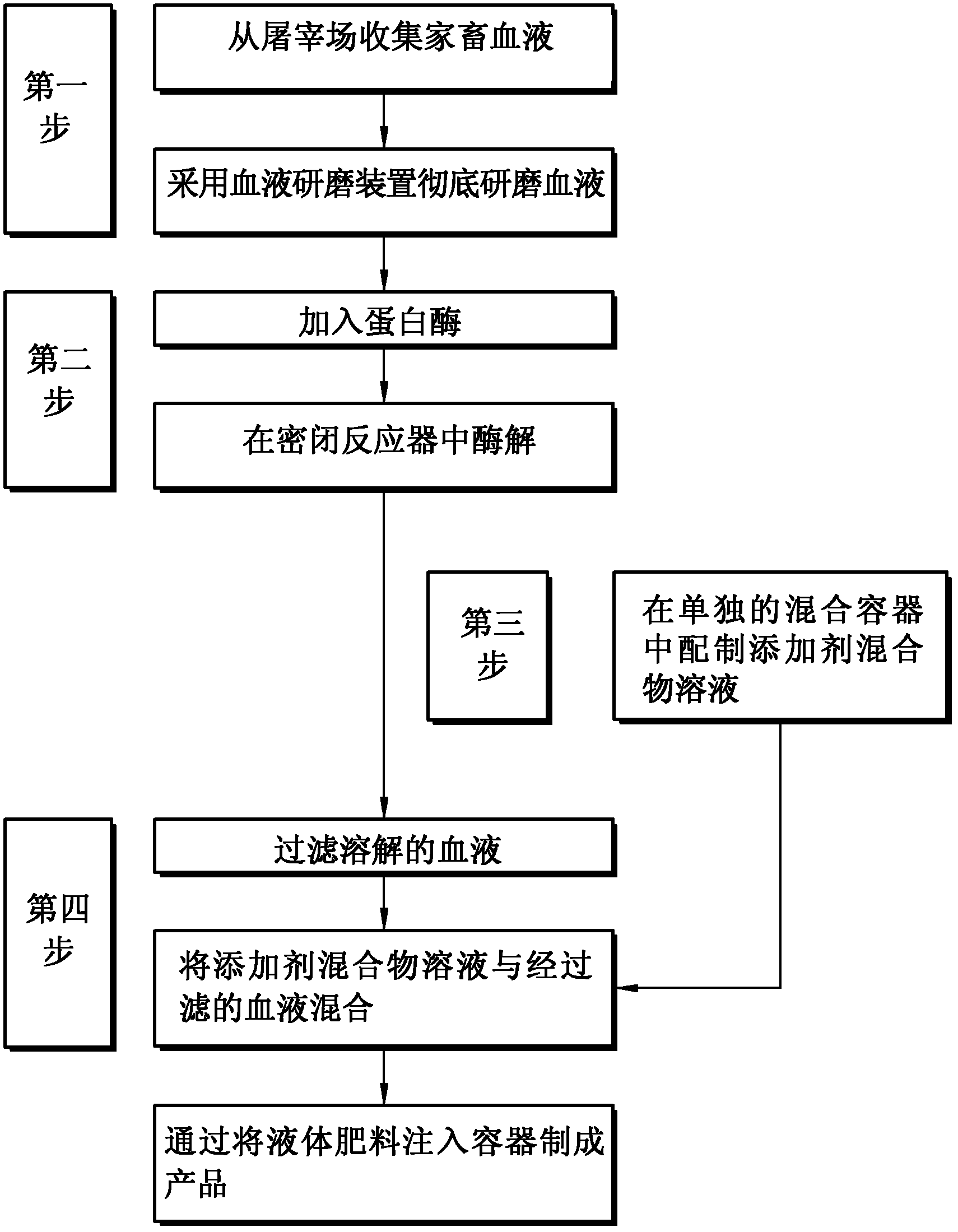

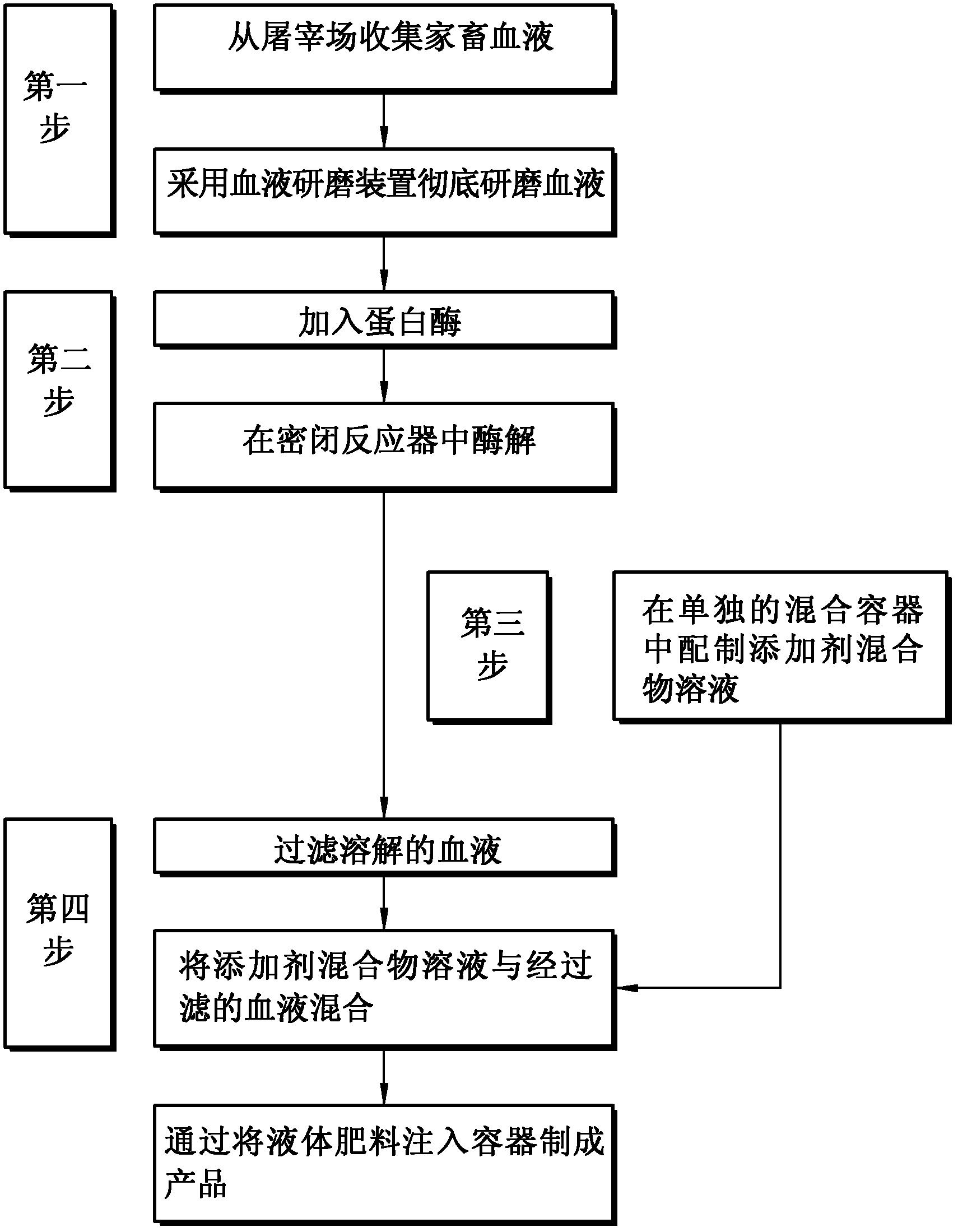

Method used

Image

Examples

Embodiment 1

[0057] : Preparation of amino acid liquid fertilizer using pig blood

[0058] Pig blood produced by the slaughterhouse was collected and thoroughly ground for 20 minutes using a blood grinding device. About 2000 cc of protease extracted from soybean was added to about 200 kg of the above-mentioned ground pig blood. Next, warm water heated to about 70°C was circulated into the triple-jacketed reactor to set the internal temperature of the reactor at about 56°C, and the above-mentioned protease-added pig blood was injected into the reactor through a pipeline through a transfer pump , the reactor was sealed and the reaction was allowed to degrade for about 11 hours. The pH of the degraded porcine blood was measured after 11 hours and determined to be about 7.7. The degradation was terminated and the reactor was left at room temperature for 3 hours to allow the reactants to cool. The results of component analysis of 18 kinds of amino acids in the liquid fertilizer prepared as ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com