Alcohol steam recovery device

A technology of recovery device and steam, applied in the direction of steam condensation, separation method, dispersed particle separation, etc., can solve the problems of high energy consumption, harsh operating conditions, pressure drop per unit bed, etc., to avoid vibration damage, prolong service life, The effect of saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

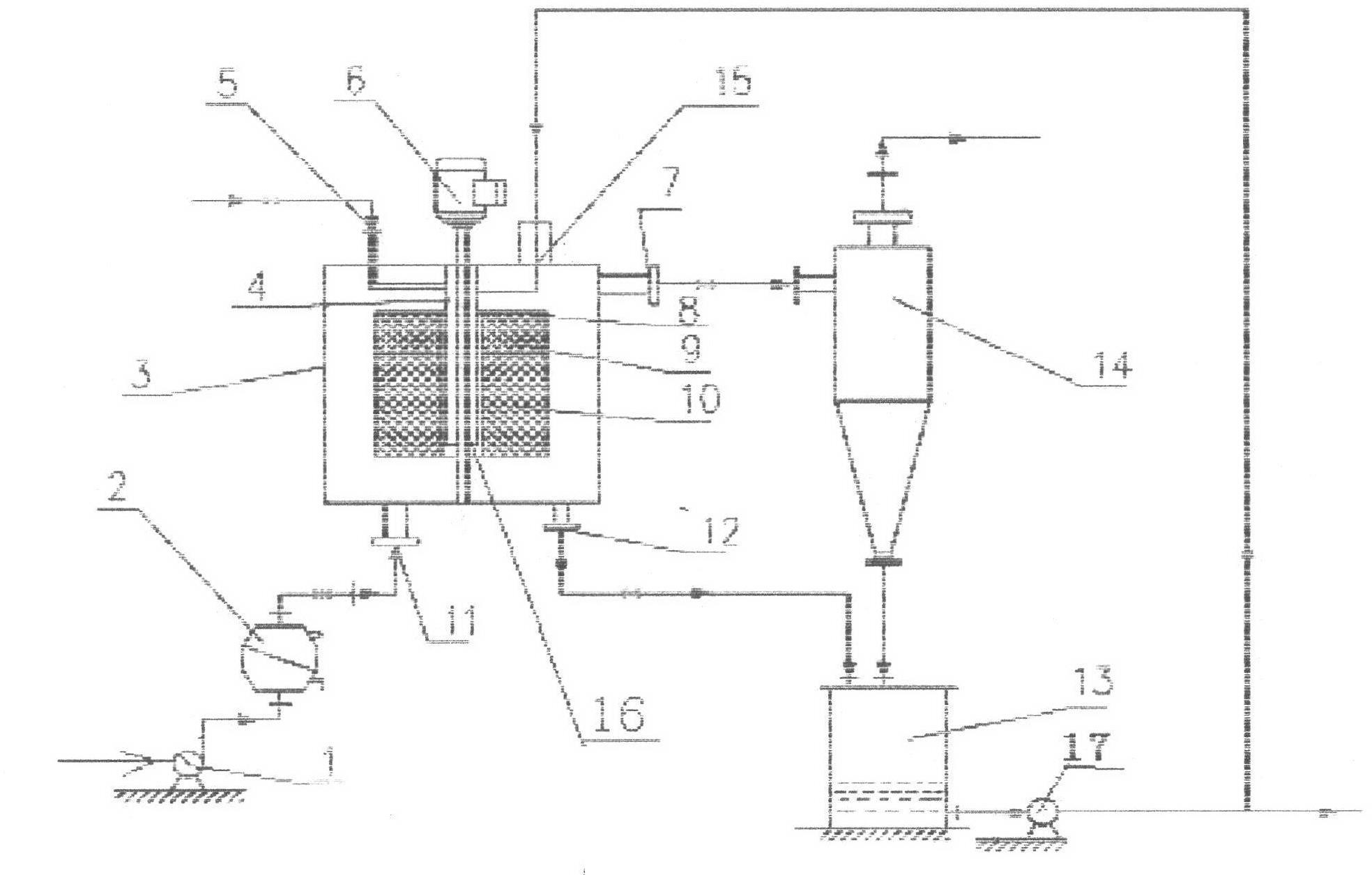

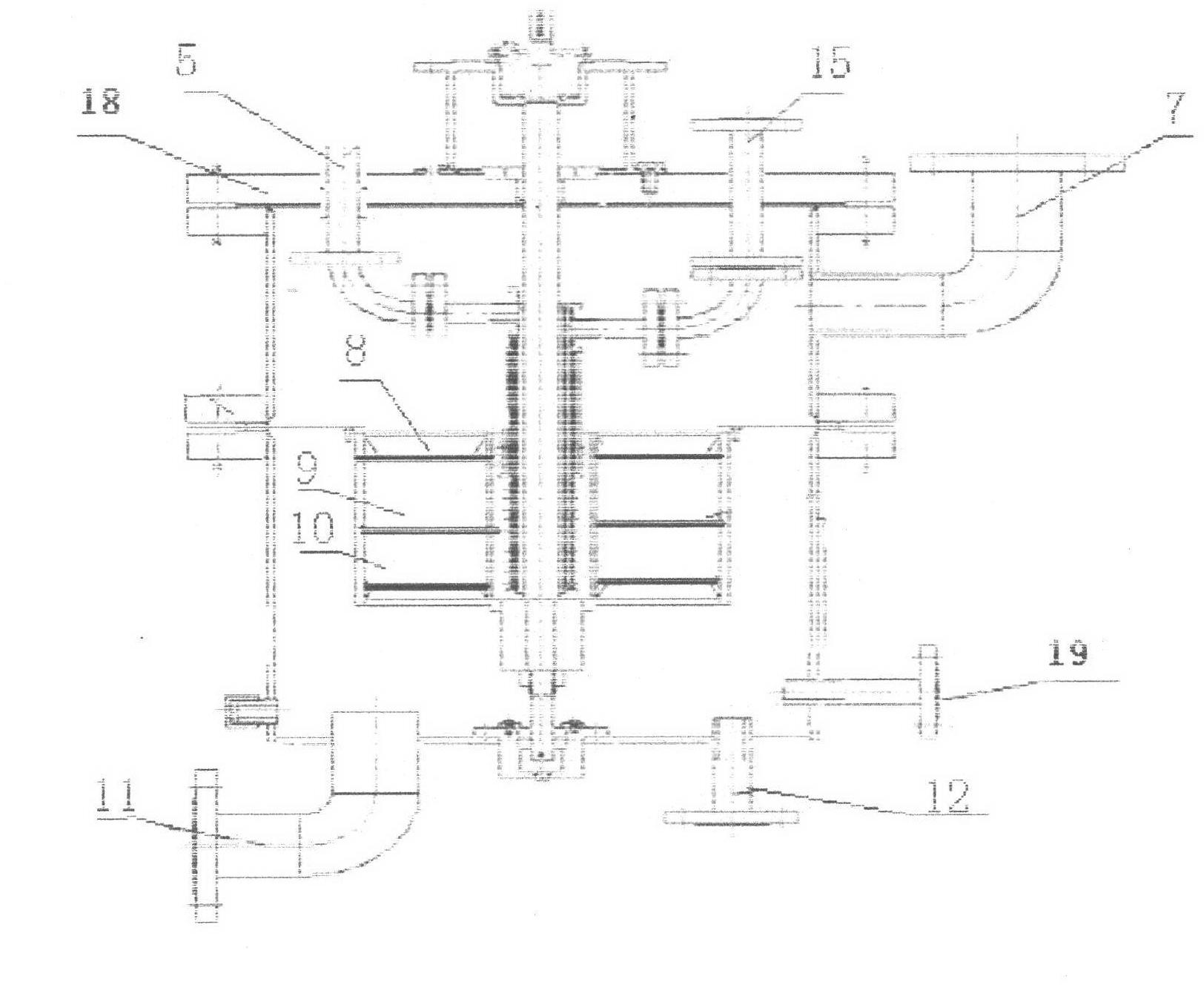

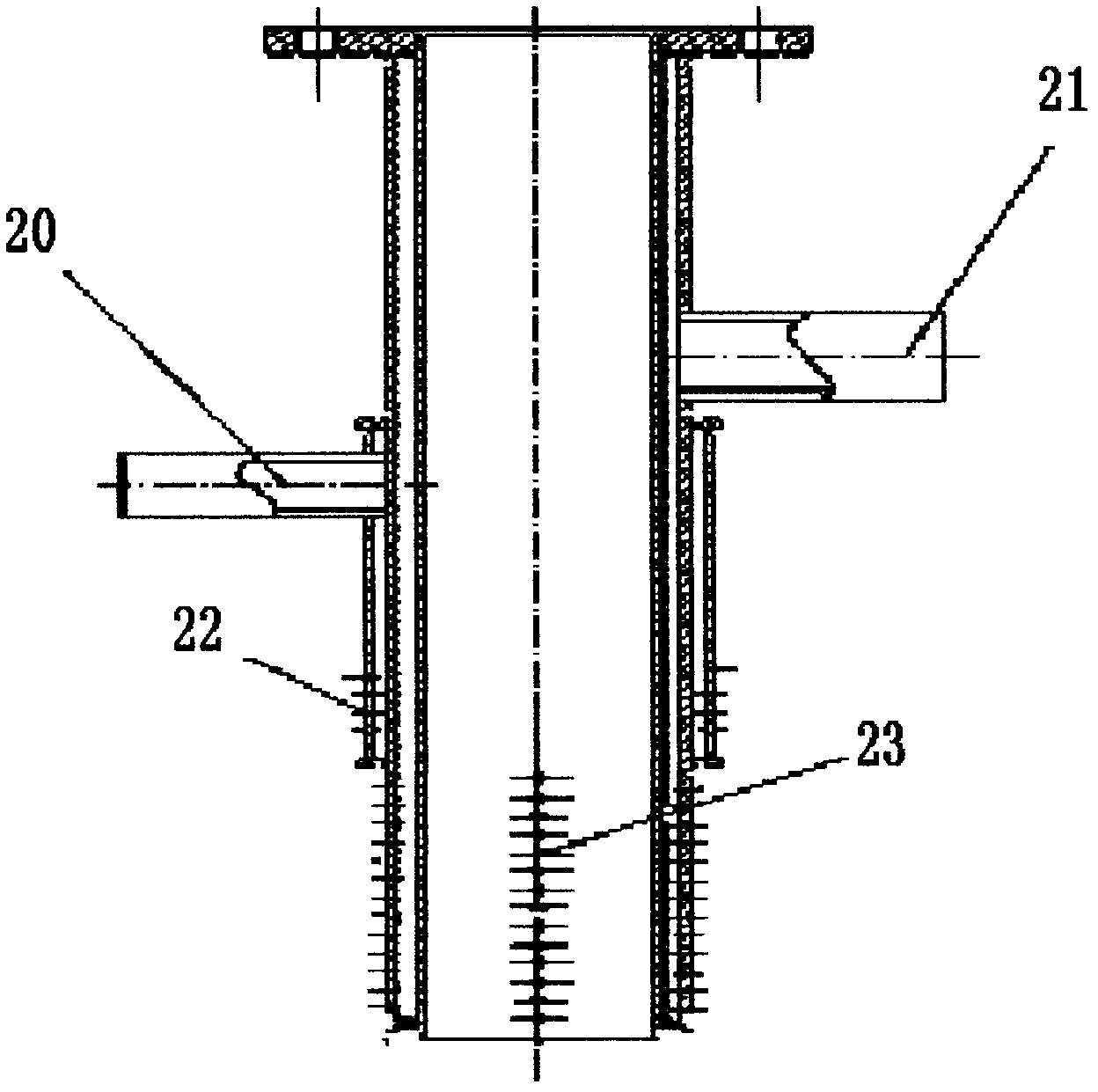

[0017] refer to Figure 1 to Figure 4 As shown, the present invention includes a vacuum pump 1, a condenser 2, a rotating packed bed 3, a circulating pump 17, a circulating liquid storage tank 13 and a cyclone separator 14, the vacuum pump is located before the condenser inlet, and the condenser 2 is installed on a rotating Before the gas inlet pipe 11 of the packed bed, the gas is condensed and separated. The upper part of the rotating packed bed 3 is provided with a cylinder upper plate 18, and a circulating liquid inlet pipe 15 and a fresh liquid inlet pipe 5 are arranged on the cylinder upper plate 18. , the circulating liquid inlet pipe 15 leads into circulating water, the fresh liquid inlet pipe 5 leads into fresh water, a motor 6 is arranged above the rotating packed bed 3, and a gas outlet pipe 7 is arranged on the side of the rotating packed bed 3 And sight glass 19, sight glass 19 is used for observing, and described cyclone separator 14 is connected with described g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com