Fiber reinforced polypropylene (PP) automobile interior decoration material and preparation method thereof

An automotive interior and fiber-reinforced technology, which is applied in the field of fiber-reinforced polypropylene automotive interior materials and its preparation, can solve problems that do not conform to the development direction of automotive materials, difficult processing, poor wear resistance and poor flexibility, and achieve mechanical The performance can be recycled and reused, the mechanical performance is excellent, and the effect of energy absorption is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

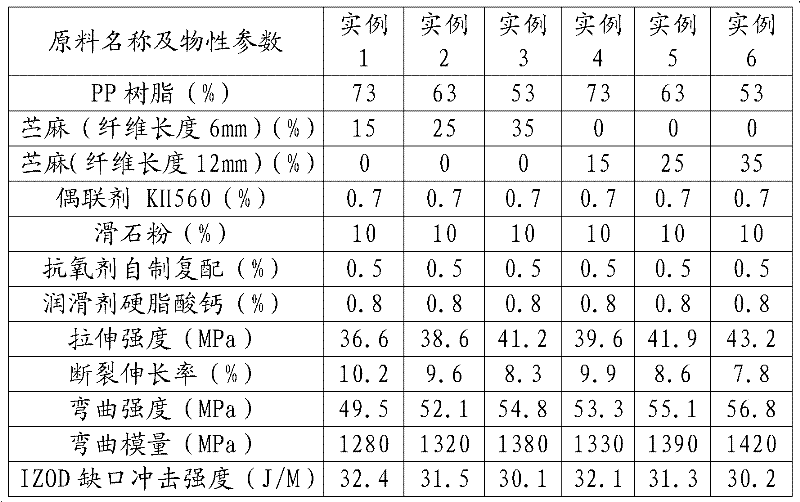

Examples

example 1

[0027] By weight percentage, 73% of PP resin, 0.7% of coupling agent, 10% of talcum powder, 0.5% of antioxidant, and 0.8% of lubricant are mixed in a high-speed mixer for 3-5 minutes, and the speed of the high-speed mixer is 800 rpm Then the mixed raw materials are placed in the feeding barrel of the parallel twin-screw extruder, ramie (the fiber content is 20%, the fiber length is 6mm) 15% is added by the exhaust port, through melt extruding, granulation, its The extrusion process is: 1 zone 170-180 ℃, 2 zone 180-190 ℃, 3 zone 180-190 ℃, 4 zone 175-185 ℃, screw speed 350-400r / min, feeding frequency 20-25Hz, melt Pressure 3.0-4.0MPa, vacuum degree -0.03~-0.06MPa.

example 2

[0029] 63% PP resin, 0.7% coupling agent, 10% talcum powder, 0.5% antioxidant, 0.8% lubricant are mixed in a high-speed mixer for 3-5 minutes by weight, and the speed of the high-speed mixer is 800 rpm Then the mixed raw materials are placed in the feeding barrel of the parallel twin-screw extruder, ramie (fiber content is 20%, fiber length is 6mm) 25% is added by the exhaust port, through melt extruding, granulation, its The extrusion process is: 1 zone 170-180 ℃, 2 zone 180-190 ℃, 3 zone 180-190 ℃, 4 zone 175-185 ℃, screw speed 350-400r / min, feeding frequency 20-25Hz, melt Pressure 3.0-4.0MPa, vacuum degree -0.03~-0.06MPa.

example 3

[0031] Mix 53% of PP resin, 0.7% of coupling agent, 10% of talcum powder, 0.5% of antioxidant, and 0.8% of lubricant by weight in a high-speed mixer for 3-5 minutes, and the speed of the high-speed mixer is 800 rpm Then the mixed raw materials are placed in the feeding barrel of the parallel twin-screw extruder, ramie (fiber content is 20%, fiber length is 6mm) 35% is added by the exhaust port, through melt extruding, granulation, its extruding The production process is: zone 1 170-180°C, zone 2 180-190°C, zone 3 180-190°C, zone 4 175-185°C, screw speed 350-400r / min, feeding frequency 20-25Hz, melt pressure 3.0-4.0MPa, vacuum degree -0.03~-0.06MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com