Continuous thermal-shrinkable stress control tube material and preparation method thereof

A stress control tube, continuous technology, applied in the field of heat shrinkable stress tube and its preparation, can solve the problems of large expansion force, unable to carry out continuous expansion, unstable product performance, complex production process, etc., and achieve stable and good product performance. The effect of mechanical properties and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

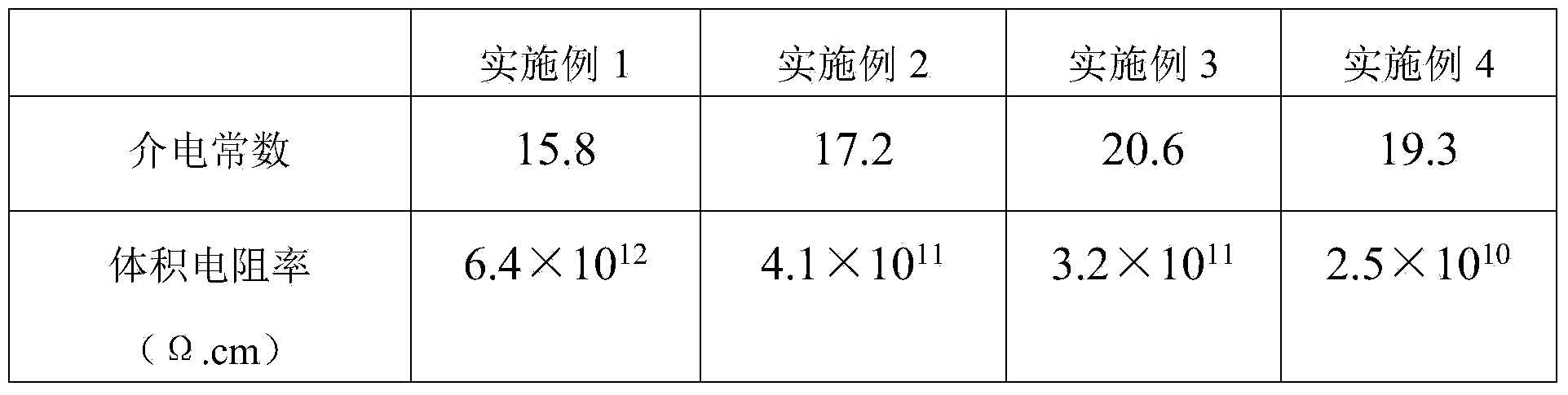

Examples

Embodiment 1

[0031] Chlorinated polyethylene: 20 kg, thermoplastic elastomer: 45 kg, carbon black: 10 kg, barium titanate: 30 kg, antioxidant: 0.5 kg, antioxidant: 0.8 kg, lubricant: 0.2 kg.

[0032] The mass percent content of chlorine in the chlorinated polyethylene is 30%. The thermoplastic elastomer is a polyolefin thermoplastic elastomer. The carbon black is thermal carbon black, the mass percentage of carbon of which is ≥99%. The dielectric constant of the barium titanate is 6000. The anti-aging agent is 2,2,4-trimethyl-1,2-dihydroquinoline polymer. The antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester. Described lubricant is calcium stearate.

[0033] The preparation method of the continuous heat-shrinkable stress control pipe material comprises the steps of: first step, accurately weighing each component of the formula; second step, melting and blending the weighed raw materials through an internal mixer, and then extruding Extrusion...

Embodiment 2

[0036] Chlorinated polyethylene: 40 kg, thermoplastic elastomer: 25 kg, carbon black: 20 kg, barium titanate: 20 kg, antioxidant: 1.0 kg, antioxidant: 0.3 kg, lubricant: 0.8 kg.

[0037] The mass percentage of chlorine in the chlorinated polyethylene is 40%. The thermoplastic elastomer is a polyolefin thermoplastic elastomer. The carbon black is thermal carbon black, the mass percentage of carbon of which is ≥99%. The dielectric constant of the barium titanate is 5000. The anti-aging agent is 2,2,4-trimethyl-1,2-dihydroquinoline polymer. The antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester. Described lubricant is zinc stearate.

[0038] The method of Example 1 was used to prepare the continuous heat-shrinkable stress control tube material of the present invention.

Embodiment 3

[0040] Chlorinated polyethylene: 25 kg, thermoplastic elastomer: 33 kg carbon black: 15 kg barium titanate: 25 kg anti-aging agent: 0.8 kg, antioxidant: 0.6 kg, lubricant: 0.6 kg.

[0041] The mass percentage of chlorine in the chlorinated polyethylene is 35%. The thermoplastic elastomer is a polyolefin thermoplastic elastomer. The carbon black is thermal carbon black, the mass percentage of carbon of which is ≥99%. The dielectric constant of the barium titanate is 6000. The anti-aging agent is 2,2,4-trimethyl-1,2-dihydroquinoline polymer. The antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester. Described lubricant is calcium stearate.

[0042] The method of Example 1 was used to prepare the continuous heat-shrinkable stress control tube material of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com