Method for pretreating and hydrolyzing microcrystalline cellulose

A microcrystalline cellulose and pretreatment technology, applied in the direction of fermentation, can solve the problems of high energy consumption, high price, and long time for dissolving cellulose, and achieve the effects of high energy consumption, low cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

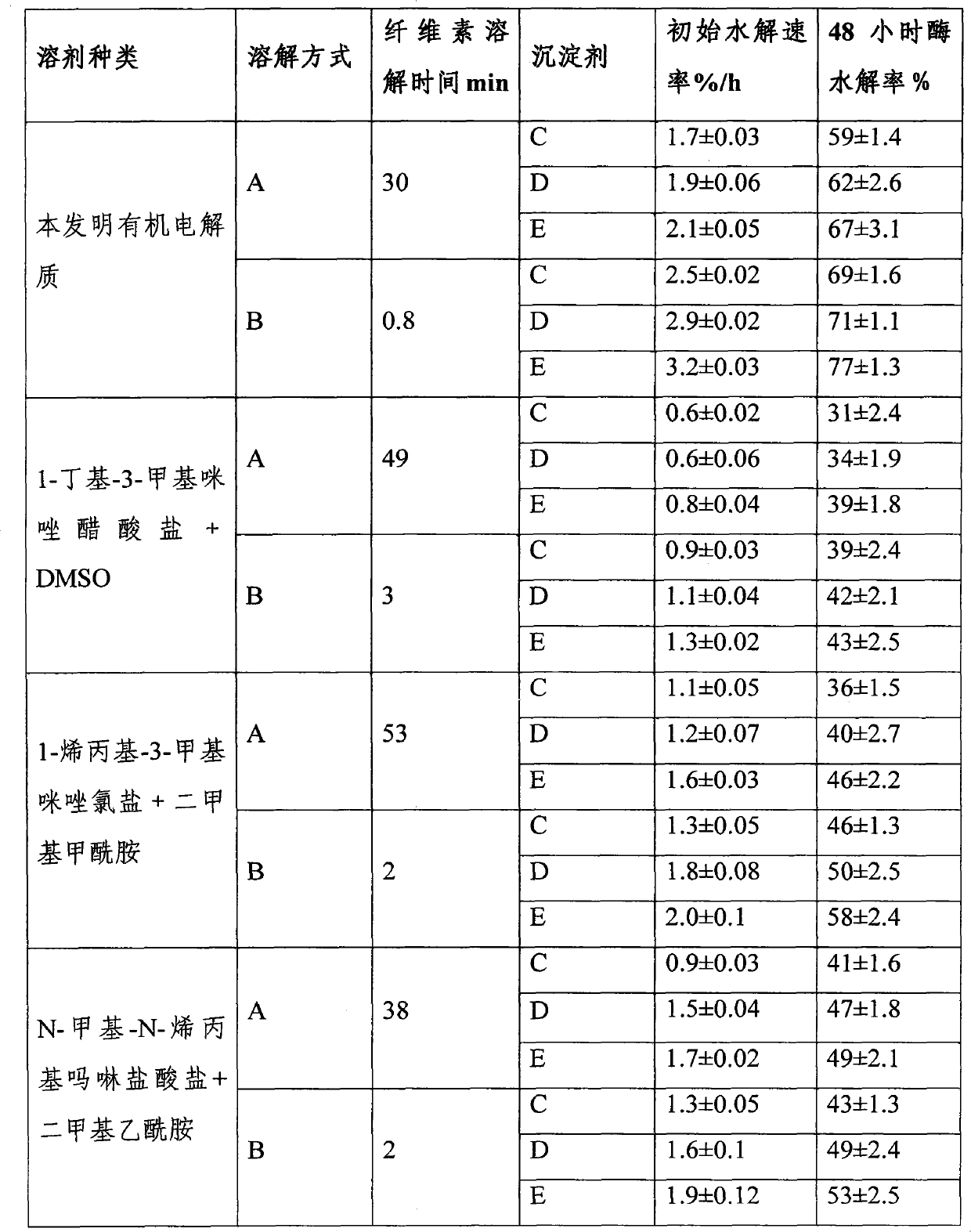

Examples

Embodiment 1

[0033] The organic solvent is a mixture of 1,3-dimethyl-2-imidazolinone (DMI), pyrrolidinone (pyrrolidinone) and sulfolane (sulfolane), wherein the three are mixed according to a molar ratio of 1:1:1; The liquid is a mixture of 3-methyl-1-butylpyrrole chloride ([BMPL]Cl) and 1,3-dimethylimidazolium diethylphosphate ([MMIM]DEP), in which the ratio of the two is 1:2 The molar ratio was mixed, and the ionic liquid was vacuum-dried at 100°C for 36 hours before use; then the organic solvent and the ionic liquid were shaken and mixed according to the volume ratio of 1:2 to form an organic electrolyte solution. Add 5% microcrystalline cellulose to the organic electrolyte solution, heat in an oil bath at 110° C. for 30 minutes, and magnetically stir at 110° C. for 20 minutes to form a clear and transparent cellulose solution.

[0034] Add 5 times volume of water at room temperature to the cellulose solution, shake vigorously and filter to obtain filtrate and colloidal regenerated cell...

Embodiment 2

[0038] The organic solvent is a mixture of 1,3-dimethyl-2-imidazolinone (DMI), pyrrolidinone (pyrrolidinone) and sulfolane (sulfolane), wherein the three are mixed according to a molar ratio of 1:2:2; The liquid is a mixture of 3-methyl-1-butylpyrrole chloride ([BMPL]Cl) and 1,3-dimethylimidazolium diethylphosphate ([MMIM]DEP), in which the ratio of the two is 1:3 The molar ratio is mixed, and the ionic liquid is vacuum-dried at 90°C for 36 hours before use; then the organic solvent and the ionic liquid are mixed according to the volume ratio of 1:1, and the organic electrolyte solution is formed. Add 5% microcrystalline cellulose to the organic electrolyte solution, microwave the mixed solution of organic electrolyte and cellulose according to the amount of 40J / g cellulose, and use 300W, 40KHz ultrasonic vibration to form a clear and transparent cellulose solution after 0.5 minutes .

[0039] Add 5 times the volume of a mixture of 10% PEG 400 and water at room temperature to...

Embodiment 3

[0043] The organic solvent is a mixture of 1,3-dimethyl-2-imidazolinone (DMI), pyrrolidinone (pyrrolidinone) and sulfolane (sulfolane), wherein the three are mixed according to a molar ratio of 1:3:2; The liquid is a mixture of 3-methyl-1-butylpyrrole chloride ([BMPL]Cl) and 1,3-dimethylimidazolium diethylphosphate ([MMIM]DEP), in which the ratio of the two is 1:2 The molar ratio is mixed, and the ionic liquid is vacuum-dried at 95°C for 40 hours before use; then the organic solvent and the ionic liquid are mixed according to the volume ratio of 1:1, and the organic electrolyte solution is formed. Add 5% microcrystalline cellulose to the organic electrolyte solution, microwave heating at room temperature according to the radiation dose of 30 J / g-cellulose, and magnetically stir at 100 rpm for 10 minutes to form a clear and transparent cellulose solution.

[0044] Add 5 times the volume of a mixed solution of 10% ethanol and water at room temperature to the cellulose solution, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com