Method for preparing in situ titanium-based composite material and part

An in-situ technology for titanium-based composite materials, which is applied in the field of preparation of in-situ titanium-based composite materials and their parts, can solve problems such as difficult to ensure uniform composition, affect the performance of composite materials and add reinforcements, and achieve no pollution at the interface, High temperature mechanical properties, the effect of producing fine particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Preparation of thin-walled Ti60+5.4wt.%TiC in-situ titanium-based composite material

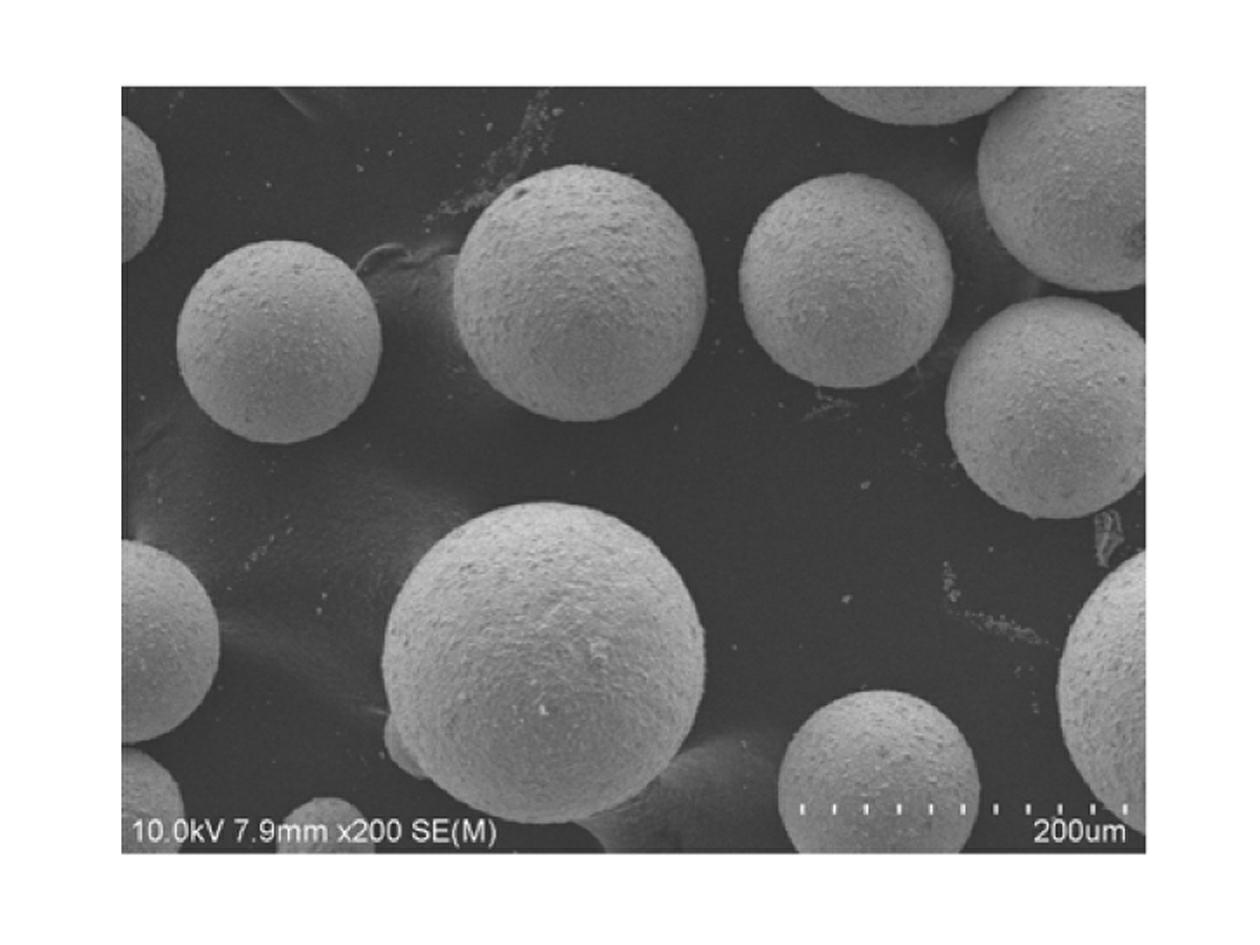

[0024] Weigh a certain amount of Ti60 titanium alloy spherical powder (94.6wt.%) with a particle size of 38~250mm and TiC particles (5.4wt.%) of 2~3 mm and place them in a plastic bottle, and add zirconia balls 10 times the weight of the powder at the same time , mixed on an ordinary mixer for 8 hours, so that the fine TiC particles are completely embedded in the surface of the coarse-grained Ti60 titanium alloy powder, and the mixed powder is obtained. The shape of the mixed powder is as follows Picture 1-1 As shown, the mixed powder maintains a complete spherical shape and has good fluidity.

[0025] On the laser melting deposition system, the mixed powders transported synchronously by laser melting deposition are used to prepare thin-walled titanium-based composite materials in situ by layer-by-layer deposition. Under the action of the carrier gas, the mixed powder is s...

Embodiment 2

[0029] Embodiment 2: Preparation of TC4+9wt.%TiB 2 Thin-walled in situ titanium matrix composites

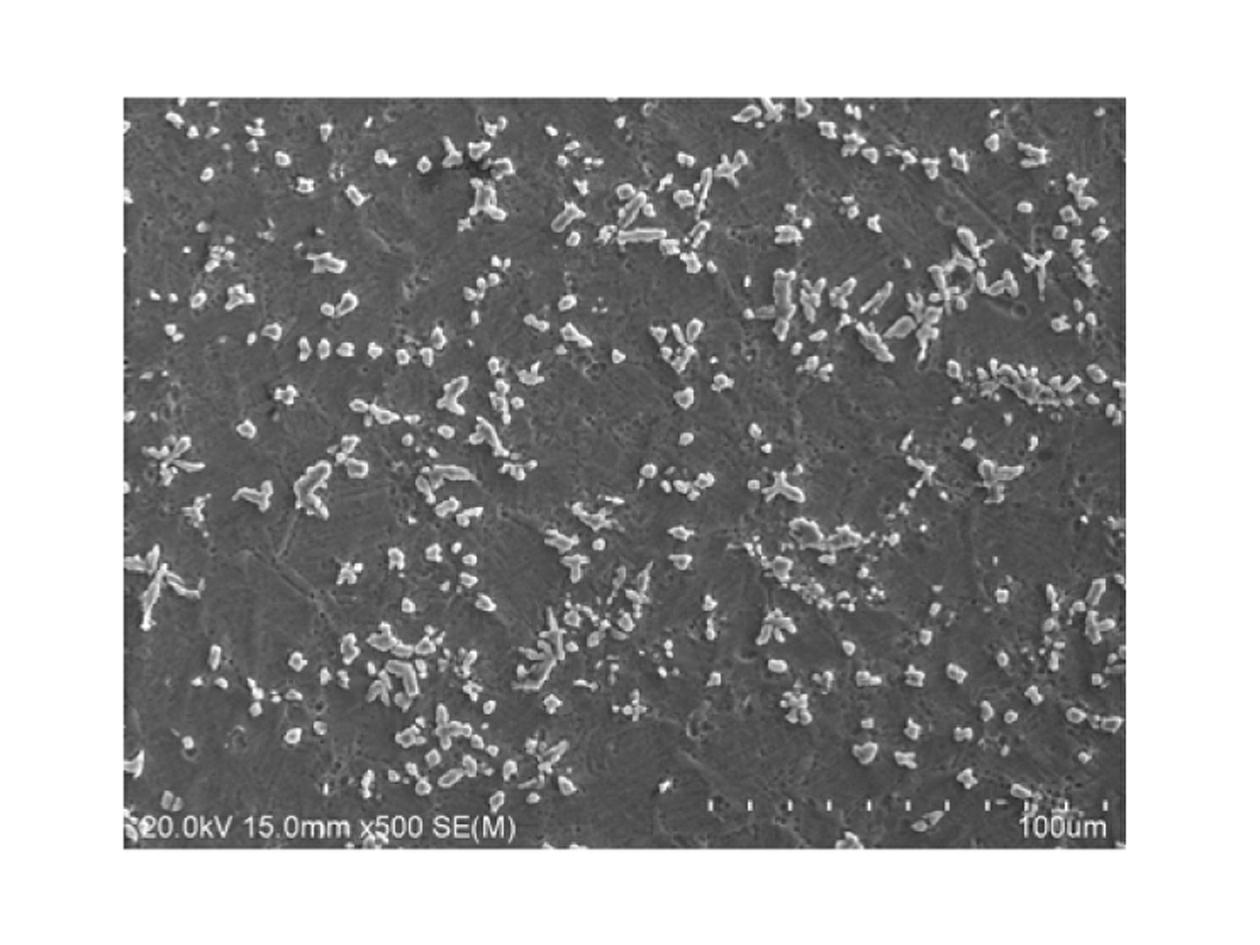

[0030] Weigh a certain amount of 38~250mm TC4 titanium alloy powder (91wt.%) and 2~4 mm TiB 2 Particles (9wt.%) were placed in a plastic bottle, and zirconia balls 20 times the weight of the powder were added at the same time, and mixed on a common mixer for 12 hours, so that the fine TiB 2 The particles are completely embedded in the surface of the coarse-grained TC4 titanium alloy powder to obtain a mixed powder. The morphology of the mixed powder is as follows diagram 2-1 As shown, the mixed powder maintains a complete spherical shape and has good fluidity.

[0031] On the laser melting deposition system, the mixed powders transported synchronously by laser melting deposition are used to prepare thin-walled titanium-based composite materials in situ by layer-by-layer deposition. Under the action of the carrier gas, the mixed powder is sent into the laser molten pool forme...

Embodiment 3

[0035] Embodiment 3: preparation TC11+ (3wt.%TiB 2+5.4wt.%TiC) thin-walled in-situ titanium-based composites

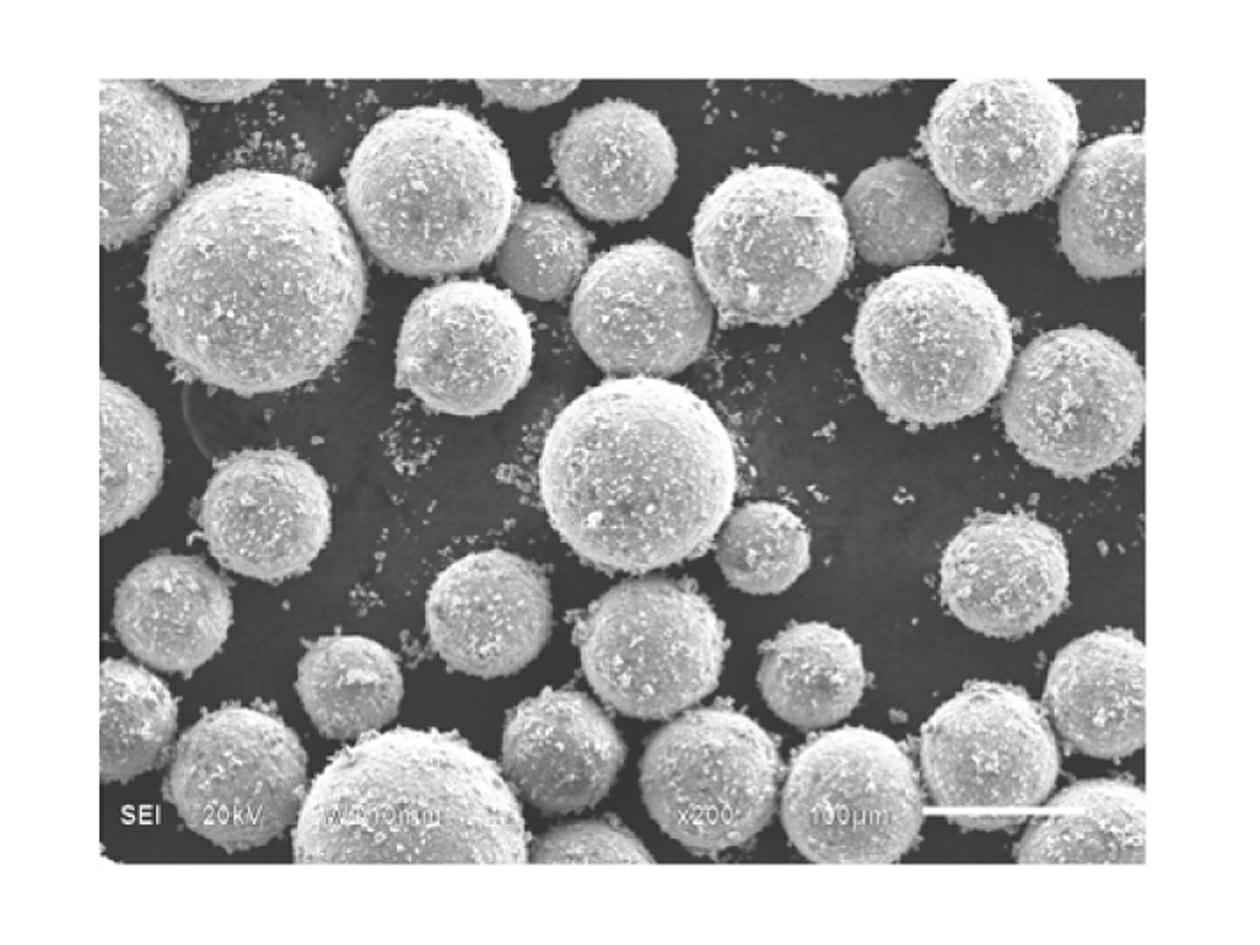

[0036] Weigh a certain amount of 38~250 mm TC11 titanium alloy powder (91.6wt.%) and 2~4 mm TiB 2 Granules (3wt.%) and 2~3 mm TiC particles (5.4wt.%) were placed in a plastic bottle, and zirconia balls 10 times the weight of the powder were added at the same time, and mixed on a common mixer for 12 hours to make the fine TiB 2 and TiC particles are completely embedded in the surface of the coarse-grained TC11 titanium alloy powder to obtain a mixed powder, which maintains a complete spherical shape and has good fluidity.

[0037] On the laser melting deposition system, the mixed powders transported synchronously by laser melting deposition are used to prepare thin-walled titanium-based composite materials in situ by layer-by-layer deposition. Under the action of the carrier gas, the mixed powder is sent into the laser molten pool formed by the high-power laser throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com