Household textile product with insecticidal effect and processing method thereof

A textile and household technology, applied in the field of household textiles, can solve the problems of harmfulness to the human body, complex components, environmental pollution, etc., and achieve the effects of preventing excessive degradation, safeguarding human health, and improving human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

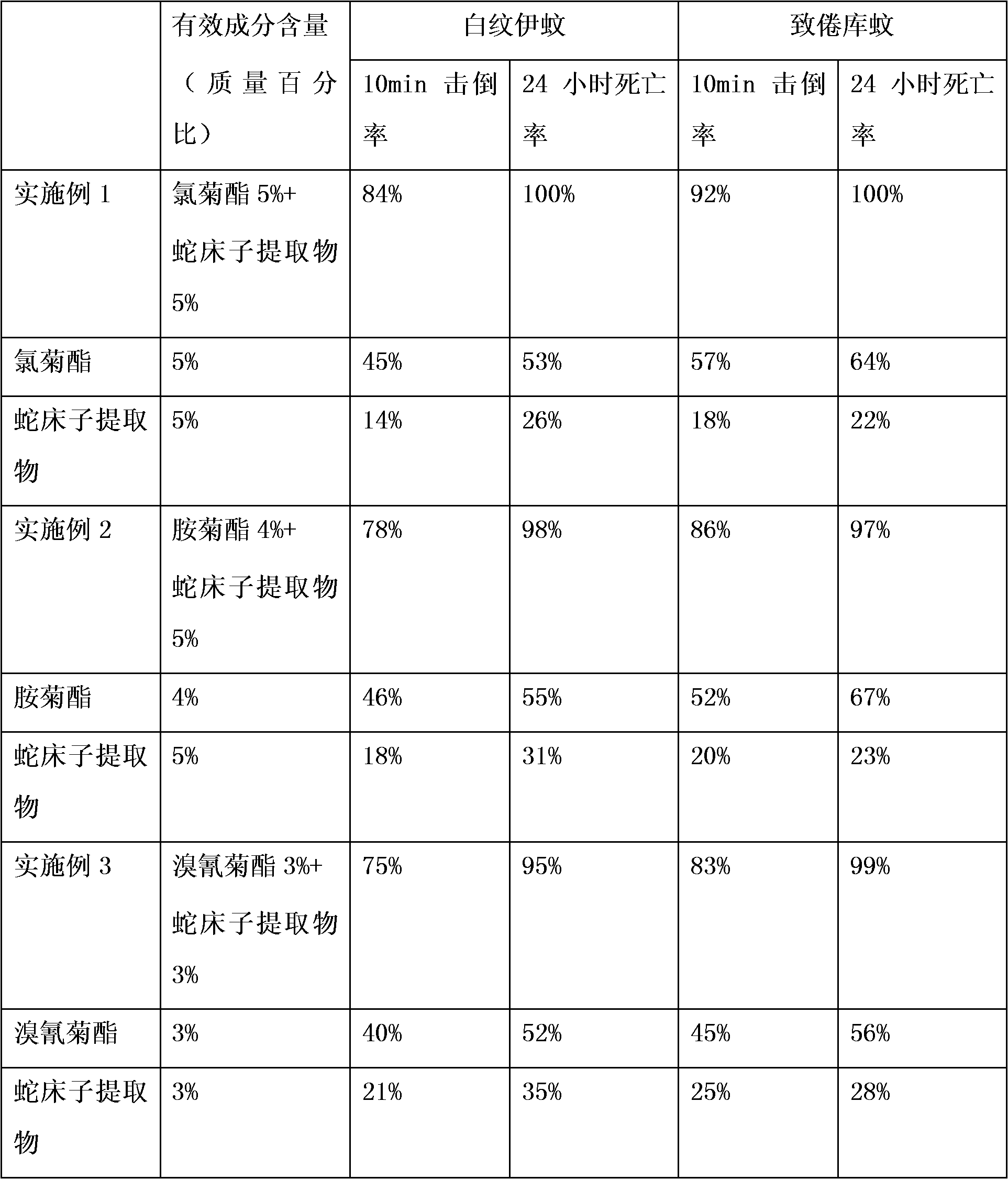

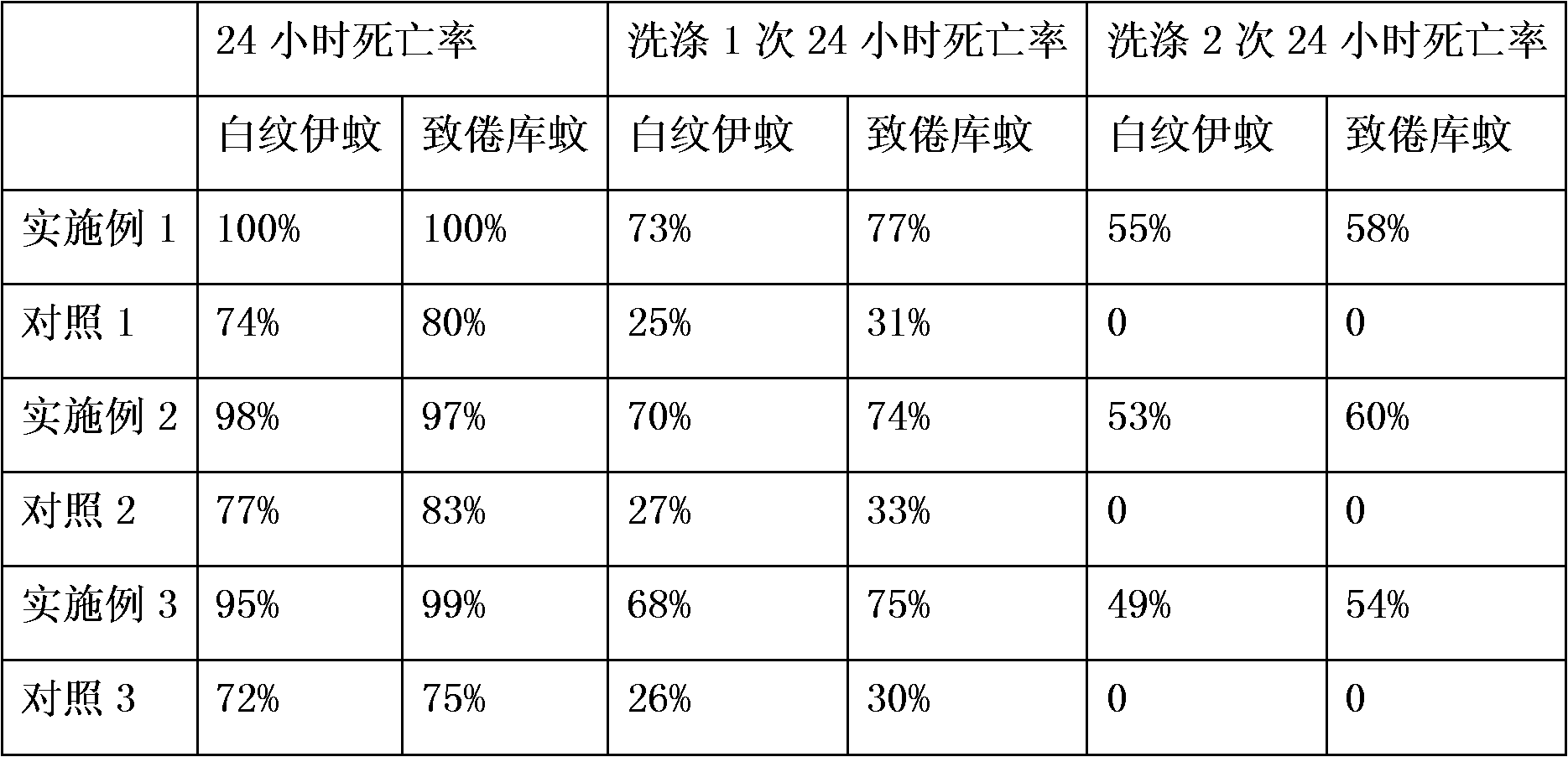

Embodiment 1

[0052] Example 1 : 10% permethrin Cnidium insect repellant for treating textile fabrics

[0053] The insect repellant is prepared by mixing the following components in weight percent:

[0054] Permethrin 5%

[0055] Cnidium extract 5%

[0056] Ethanol 70%

[0057] Sodium dodecylbenzenesulfonate 10%

[0058] UV absorber UV-P 0.3%

[0059] The balance is water.

[0060] Textile fabric processing method:

[0061] (1) according to above-mentioned formula preparation insect repellant;

[0062] (2) Pass the cotton textile fabric through the insect repellant at a speed of 35 m / min. In this process, the uniform pressure on the fabric needs to be kept at 1.5 atmospheres;

[0063] (3) The fabric passed through the insect repellent agent is dried by an oven at a high temperature of 145° C. at a speed of 35 m / min. The home textile fabric with insecticidal effect can be prepared.

Embodiment 2

[0064] Example 2 : 9% Tetramethrin Cnidium insect repellant for treating textile fabrics

[0065] The insect repellant is prepared by mixing the following components in weight percent:

[0066] Tetramethrin 4%

[0067] Cnidium extract 5%

[0068] Methanol 61%

[0069] Spann 20 15%

[0070] UV absorber UVP-327 0.5%

[0071] The balance is water.

[0072] Textile fabric processing method:

[0073] (1) according to above-mentioned formula preparation insect repellant;

[0074] (2) Pass the cotton and hemp textile fabric through the insect repellant at a speed of 40 m / min. This process needs to keep the uniform pressure on the fabric at 1.8 atmospheres;

[0075] (3) The fabric passed through the insect repellent agent is dried by an oven at a high temperature of 160° C. at a speed of 40 m / min. The home textile fabric with insecticidal effect can be prepared.

Embodiment 3

[0076] Example 3 : 6% deltamethrin Cnidium insect repellant for treating textile fabrics

[0077] The insect repellant is prepared by mixing the following components in weight percent:

[0078] Deltamethrin 3%

[0079] Cnidium extract 3%

[0080] Ethanol 64%

[0081] Tween 80 8%

[0082] UV absorber UV-531 0.2%

[0083] The balance is water.

[0084] Textile fabric processing method:

[0085] (4) according to above-mentioned prescription preparation insecticide;

[0086] (5) Pass the cotton textile fabric through the insect repellant at a speed of 50 m / min. This process needs to keep the uniform pressure on the fabric at 2.0 atmospheres;

[0087] (6) The fabric after passing the insect repellant is dried by an oven at a high temperature of 180° C. at a speed of 50 m / min. The home textile fabric with insecticidal effect can be prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com