Coaxial cable connector with integrated outer conductor

A coaxial cable and outer conductor technology, applied in the direction of conductive connection, permanent deformation, connection, connection, etc., can solve the problem of unstable mechanical performance indicators of cable components, poor mechanical performance indicators of coaxial cables, and electrical performance indicators of cable components. Poor and other problems, to avoid poor contact, ensure electrical and mechanical properties, fast and reliable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

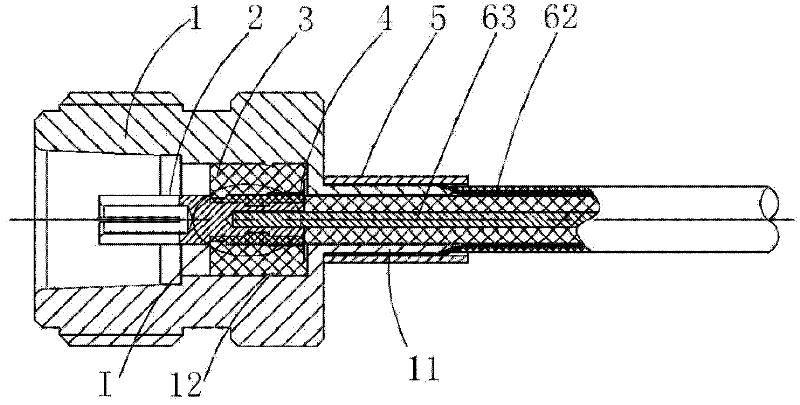

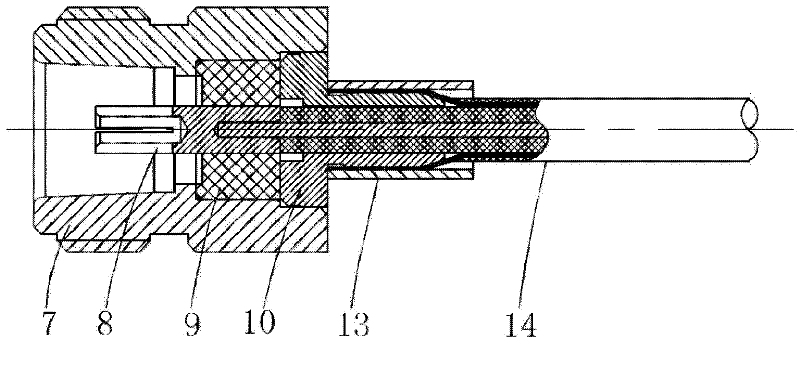

[0016] Example: see figure 1 , 2 , the outer conductor of this embodiment is an integral cable connector, which includes:

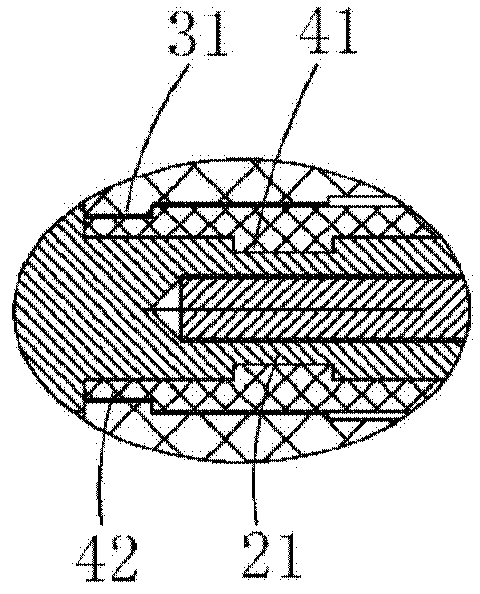

[0017] The inner conductor 2, the insulating medium 4, the supporting medium 3 and the outer conductor 1 are coaxially arranged sequentially from the inside to the outside. The tail of the inner conductor 2 is provided with a welding hole along its axial direction, and the cable inner core 63 is welded in the welding hole. The tail of the outer conductor 1 is integrally provided with a shielding tube 11 , the cable outer conductor 62 is crimped on the shielding tube 11 through the crimping tube 5 , and the outer diameter of the shielding tube 11 is smaller than that of the outer conductor body.

[0018] In a specific arrangement, the inner cavity wall of the outer conductor 1 is provided with barbs 12 , and the barbs 12 and the grooves on the outer circumferential surface of the supporting medium 3 form an axial limit between the two. The inner cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com