Motor speed adjusting device

A motor speed controller and capacitor technology, which is applied in the direction of excitation or armature current control, etc., can solve the problems of high cost, inability to realize stepless speed regulation, high-frequency interference, etc., and achieve low production cost, simple circuit, and easy implementation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

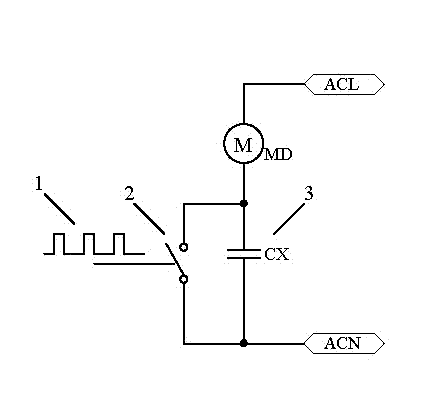

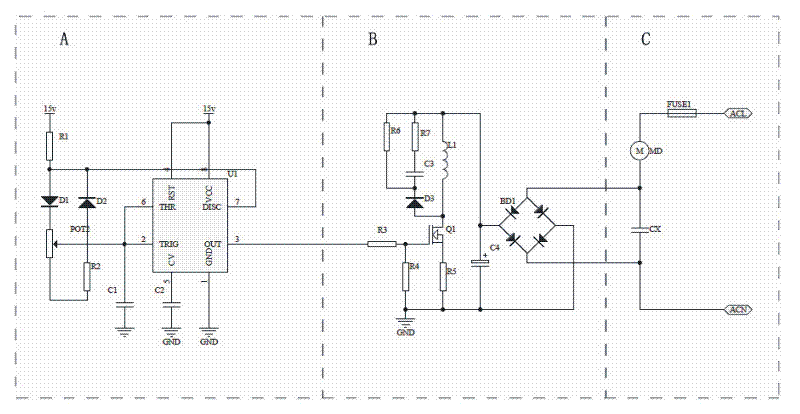

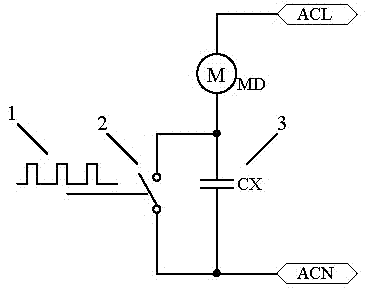

[0019] Such as figure 1 and figure 2 As shown, the PWM unit of the present invention is mainly composed of a pulse wave generation chip U1 and a variable resistor POT2, and the duty cycle of the pulse wave can be changed when POT2 is adjusted. The main control circuit controls the discharge circuit through the pulse signal. Both ends of CX in the load unit are connected to the filter capacitor C4 through the rectifier bridge stack BD1. The PWM unit outputs a pulse signal, which is added to the control pole of the power tube Q1 through the R3 of the main control circuit to control the power tube to be turned on or off. During the high-level period of the pulse wave, Q1 is turned on, so that the capacitor CX is discharged through the discharge circuit of the main control circuit; during the low-level period of the pulse wave, Q1 is turned off, the discharge circuit is disconnected, the load unit charges CX, and the capacitor is alternately charged The discharge causes the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com