Water-borne acrylic thermal insulating coating and preparation method thereof

A water-based acrylic and thermal insulation coating technology, applied in antifouling/underwater coatings, reflective/signal coatings, coatings, etc. The effect of reducing radiation heat transfer, excellent physical and chemical properties and stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

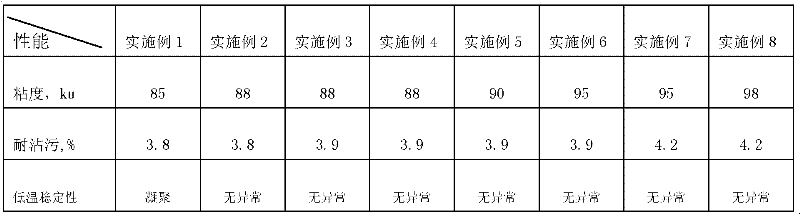

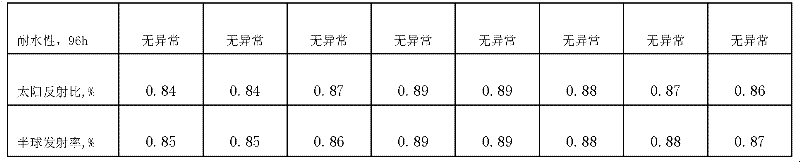

Examples

preparation example Construction

[0033] A kind of preparation method of water-based acrylic heat insulating paint of the present invention, comprises the following steps:

[0034] A. Dispersion: Stir 0.2-0.4 parts of the water-resistant dispersant SN-5027 and 5-8 parts of deionized water evenly, then add nano-silica split JY100, and use a high-speed disperser at a speed of 2000 rpm Disperse for 15-25 minutes to make nano-silica pre-dispersed slurry;

[0035] B. Homogeneously mixing and dispersing grinding: the remaining deionized water and water-resistant dispersant SN-5027, defoamer A-34, propylene glycol, titanium dioxide, calcium carbonate, thermal insulation powder S-20 and hollow glass microspheres VS5500 in sequence Add it into the mixing container and stir evenly, disperse at high speed and grind it to a fineness below 50μm through the grinding equipment;

[0036] C. Stirring detection: Add the nano-silica pre-dispersed slurry prepared in step A and the special emulsion for heat-insulating coating, fi...

Embodiment 1

[0039] A water-based acrylic heat-insulating paint, comprising the following components, in parts by weight, and each part is calculated as 10g: 300 parts of BTA-100, a special emulsion for heat-insulating paint, 50 parts of hollow glass microspheres VS5500, and nano-silica powder Body JY100 is 5 parts, titanium dioxide is 150 parts, calcium carbonate is 50 parts, heat insulation powder S-20 is 50 parts, defoamer A-34 is 2 parts, water-resistant dispersant SN-5027 is 5 parts, the composition Membrane aid DalpadC is 20 parts, thickener TT-935 is 5 parts, propylene glycol is 5 parts, fungicide MV is 1 part, fungicide EPW is 1 part, and deionized water is 250 parts.

[0040] The above-mentioned water-based heat-insulating reflective coating and its preparation method are first to stir 0.3 parts of water-resistant dispersant and 6 parts of deionized water evenly, then add nano-silica powder, and disperse at high speed for 20 minutes to prepare nano-silica pre-coating. dispersion s...

Embodiment 2

[0042] A kind of water-based acrylic heat insulating paint, comprises following components, by weight (parts), every part is counted as 10g:

[0043] 320 parts of BTA-100 special emulsion for thermal insulation coating, 60 parts of hollow glass microsphere VS5500, 7 parts of nano-silica powder JY100, 150 parts of titanium dioxide, 70 parts of calcium carbonate, heat insulation powder S-20 50 parts, defoamer A-34 is 2 parts, water-resistant dispersant SN-5027 is 7 parts, film-forming aid DalpadC is 30 parts, thickener TT-935 is 7 parts, propylene glycol is 10 parts, and anti-water dispersant is 7 parts. The mold agent EPW is 1.0 parts, the fungicide MV is 1.0 parts, and the deionized water is 280 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com