High-Cr ferrite stainless steel and manufacturing method thereof

A manufacturing method and ferrite technology, applied in the field of stainless steel, can solve the problems of high-chromium ferritic stainless steel industrial production difficulties, avoiding the brittle temperature zone of the σ phase, etc., and achieve good room temperature toughness, excellent resistance to pitting corrosion, and reduced The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

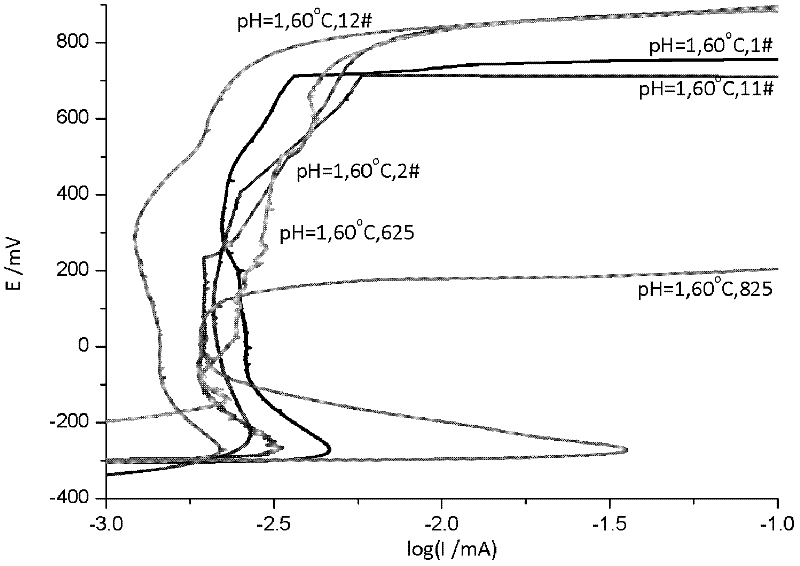

[0058] Example 1: Pitting corrosion resistance of high Cr ferritic stainless steel samples

[0059] According to the national standard GB4334.9-84, the pitting potential of four samples of high-Cr ferritic stainless steel and the comparison materials 625 and 825 corrosion-resistant alloys were tested by potentiodynamic method under different media conditions ( figure 1 ). The results show that the 2# and 12# samples with higher pitting equivalent (PRE) have the highest pitting potentials, which are equivalent to the comparison material 625 corrosion-resistant alloy, and the pitting potentials of 1# and 11# samples with lower pitting equivalents are relatively higher. Low, the pitting potential of the above five materials is much higher than that of the comparison material 825 corrosion-resistant alloy, indicating that high Cr and Mo content has a significant effect on improving pitting corrosion resistance.

Embodiment 2

[0060] Example 2: Critical Pitting Potential (CPT) of high-chromium ferritic stainless steel samples

[0061] Table 3 G48-C test results of 1#, 2#, 11# and 12# samples

[0062]

[0063] According to the ASTM-G48 method of the American Society for Testing and Materials, the critical pitting temperature of four samples of high-Cr ferritic stainless steel was tested. It can be seen from Table 3 that samples 1# and 11# with low Cr content failed to pass the test at 65°C. Serious macroscopic corrosion pits appeared on the surface of the samples, and the average corrosion rate was 3 times higher than that of the other two samples. ~4 orders of magnitude. After pickling and passivation treatment, although the corrosion rate has decreased, it is still 2 to 3 orders of magnitude higher than that of 2# and 12# samples. The 2# and 12# samples with higher Cr content not only passed the test at 65°C, but also had an average corrosion rate of only 10-2 after the test at 70°C, which ind...

Embodiment 3

[0064] Example 3: Crevice corrosion resistance of high Cr ferritic stainless steel samples

[0065] Table 4 Crevice corrosion test results of 44660 high-chromium ferritic stainless steel

[0066]

[0067]

[0068] According to the American Society for Testing and Materials standard ASTM-G48, the crevice corrosion performance of high-Cr ferritic stainless steel samples and comparison materials 625 and 825 alloys in different media was tested at a test temperature of 50 °C (Table 4). 6% FeCl in the absence of hydrochloric acid 3 After 72 hours of testing at 50°C in the solution, the weight loss of 1# and 11# samples exceeded the critical value of 1g, indicating that the two samples with low Cr content could not pass the test; while 2#, 12# and 625 alloys lost weight are very small, and the weight loss of the above three samples is much smaller than that of 825 alloy. Add 1% hydrochloric acid to a concentration of 6% FeCl 3 After 72 hours of testing at 50°C in the soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature impact toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com