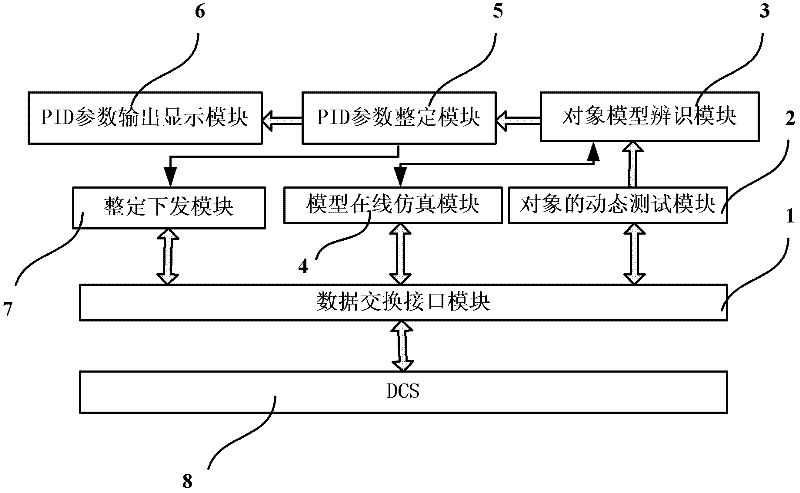

System and method for optimizing and adjusting controller parameters in distributed control system

A distributed system and controller technology, applied in electric controllers, controllers with specific characteristics, etc., can solve problems such as unreasonable settings and difficult PID parameter tuning, and achieve stable objects, strong anti-interference, and stable device control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

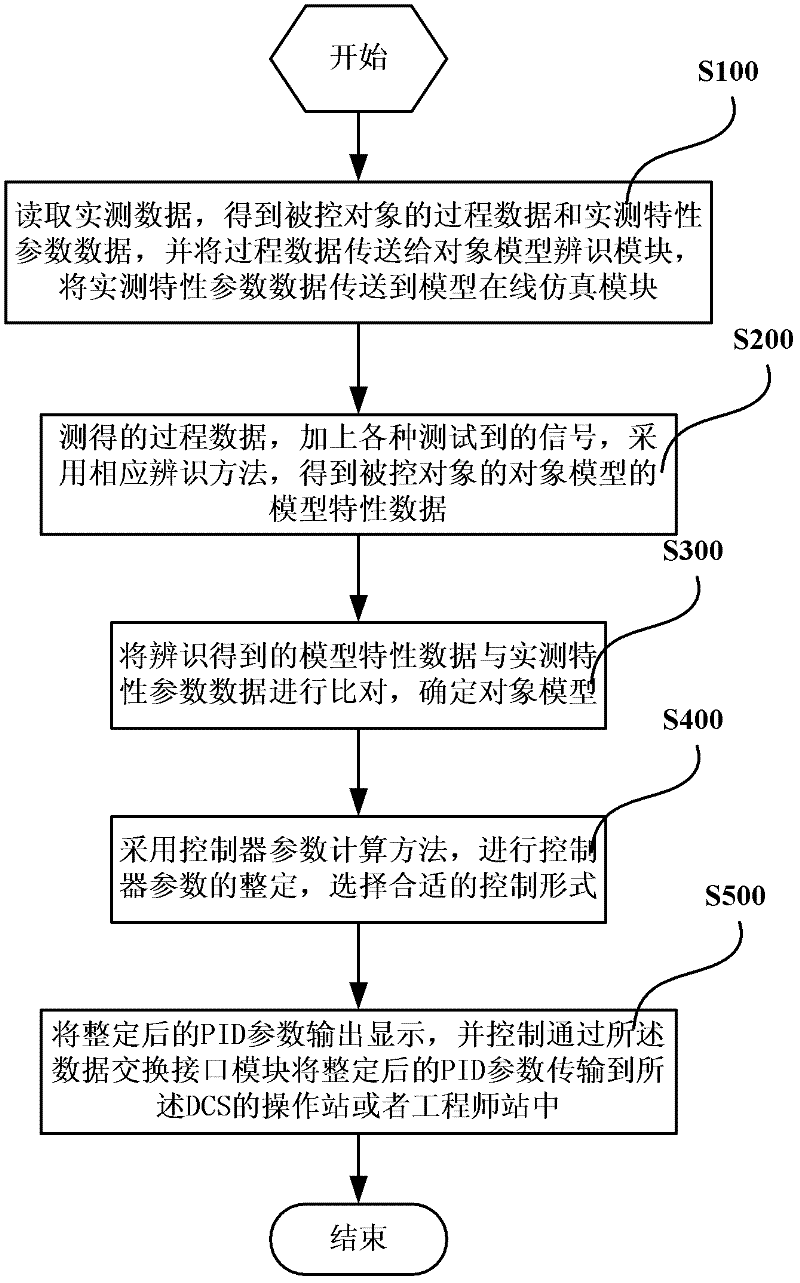

Method used

Image

Examples

Embodiment 1

[0098] For example, LIC110 and LIC111, these two control loops are often manually controlled, resulting in poor electrical desalination effect and fluctuations in the liquid level at the bottom of the initial distillation tower.

[0099] LIC111 controls the water level settled in the north tank of electric desalination, and sends water to the south tank of electric desalination at the same time. The parameters of the PID controller of this loop: before optimization: KP=0.8; KI=1; KD=0, FT=0; after optimization: KP=0.59; KI=70; KD=0, FT=0; Figure 4 As shown, the first half of the picture shows the control trend before optimization. The valve position fluctuates from 0 to 95%. The fluctuation of the boundary position brings about the fluctuation of the liquid level at the bottom of the primary distillation tower, which affects the stability of crude oil feed and deteriorates the The effect of electric desalination. After parameter optimization, from Figure 4 In the middle an...

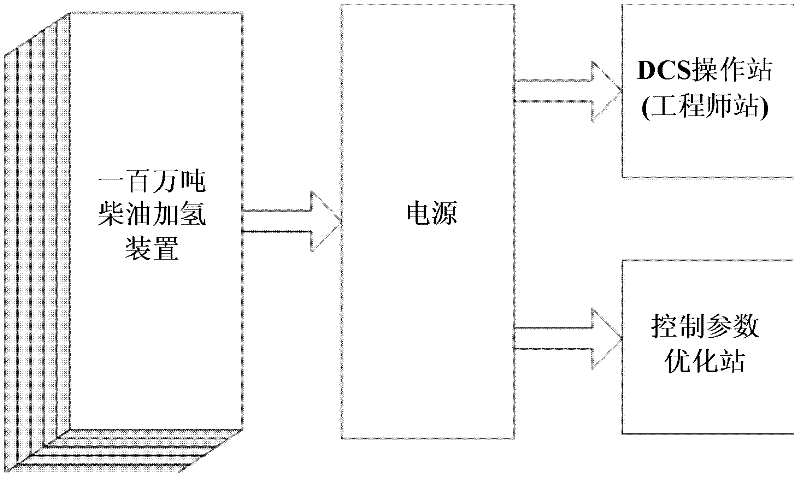

Embodiment 2

[0102] The heavy oil at the bottom of the atmospheric tower is pumped out by pump 103 in four ways to the decompression heating furnace, heated to 382°C and then combined in four ways, and then enters the decompression tower 104 through the oil transfer line. The decompression tower has 7 sections of packing. The oil vapor at the top of the tower is distilled from the top of the tower, condensed and cooled by the water cooler (110 / l-4), and the uncondensed gas enters the first-stage vacuum pump for vacuuming, and then enters the first-stage water cooler (cold 111 / 1.2.3) cooling, the non-condensed gas is evacuated by the secondary vacuum pump, enters the secondary water cooler (112) for cooling, and the non-condensable gas is discharged from the top of the cooling 112 to the heating furnace to be burned or discharged to the atmosphere. The furnace temperature and furnace outlet temperature of the decompression heating furnace are controlled in cascade, the furnace outlet tempera...

Embodiment 3

[0105] In petrochemical production, the control of the liquid level of the high-pressure separator is very important and critical. If the control is not good, the high pressure of the high pressure separator is connected to the low pressure separator in series, which is easy to cause an explosion. The high-pressure separator in a petrochemical refinery was connected to low pressure due to improper liquid level control, which caused the explosion of the device and caused a serious accident. Because this circuit is very critical, but this circuit is very difficult to control, the operators and craftsmen are helpless, so they have to operate it manually, and the operators have to pay attention to the liquid level at all times, which is very hard.

[0106] After adopting the optimal setting system and method of controller parameters in the collection and distribution system of the embodiment of the present invention, the liquid level of the high-pressure separator has been put int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com