Bio-fermented component vegetable protein and preparation method thereof

A plant protein and biological fermentation technology, applied in animal feed, animal feed, application, etc., can solve the problems of unbalanced amino acid composition ratio, low crude protein content and low nutritional value of plant protein, and alleviate the shortage of high-quality protein resources. , the effect of reducing crude fiber content and increasing amino acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Raw materials and dosage

[0022] Main raw materials: sunflower meal 32%, cotton meal 30%, rapeseed meal 30%, safflower meal 8%;

[0023] Fermentation strain: brewer's yeast ( Saccharomyces cerevisiae ), lactic acid bacteria ( Lactobacillus delbrueckii ), Candida tropicalis ( Candida tropicalis );

[0024] Brewer's yeast, lactic acid bacteria, and Candida tropicalis were all purchased from the China Industrial Microbiology Culture Collection Management Center;

[0025] Carry out three-stage expansion cultivation of these three strains according to conventional microbial culture methods, and mix them in proportion. The weight percentage after mixing is 40% of Saccharomyces cerevisiae, 30% of lactic acid bacteria, and 30% of Candida tropicalis;

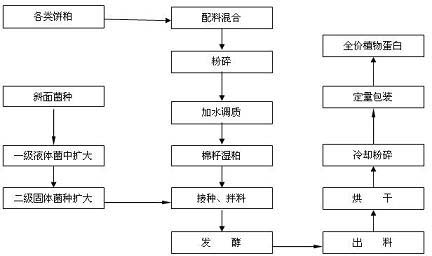

[0026] Such as figure 1 As shown, this method first selects sunflower meal with a protein content of more than 46%, cotton meal with a protein content of more than 50%, rapeseed meal with a protein content of more ...

Embodiment 2

[0035] 1. Raw materials and dosage

[0036] Main raw materials: 25% sunflower meal, 40% cotton meal, 20% rapeseed meal, 12% safflower seed meal, 2% grape seed meal, 1% tomato seed meal;

[0037] Fermentation strains: brewer's yeast, lactic acid bacteria, and Candida tropicalis, of which, brewer's yeast 45%, lactic acid bacteria 25%, and Candida tropicalis 30%;

[0038] All the other are identical with embodiment 1.

Embodiment 3

[0040] 1. Raw materials and dosage

[0041] Main raw materials: sunflower meal 25%, cotton meal 31%, rapeseed meal 21%, safflower kernel meal 10%, grape seed meal 8%, tomato seed meal 5%;

[0042] Fermentation strains: beer yeast, lactic acid bacteria, and candida tropicalis, of which, beer yeast 50%, lactic acid bacteria 20%, and candida tropicalis 30%;

[0043] All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com