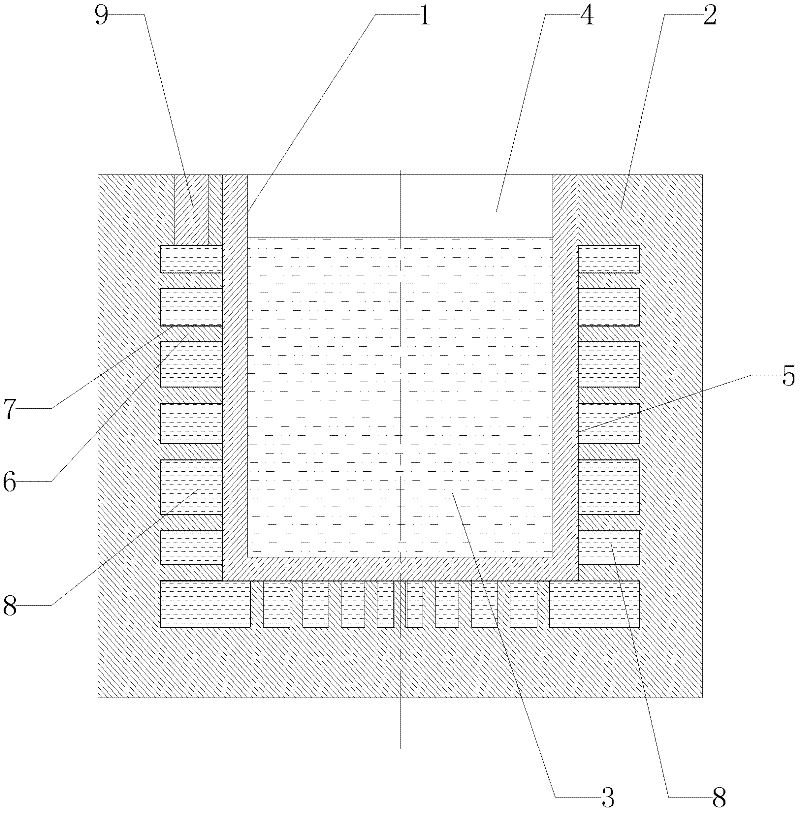

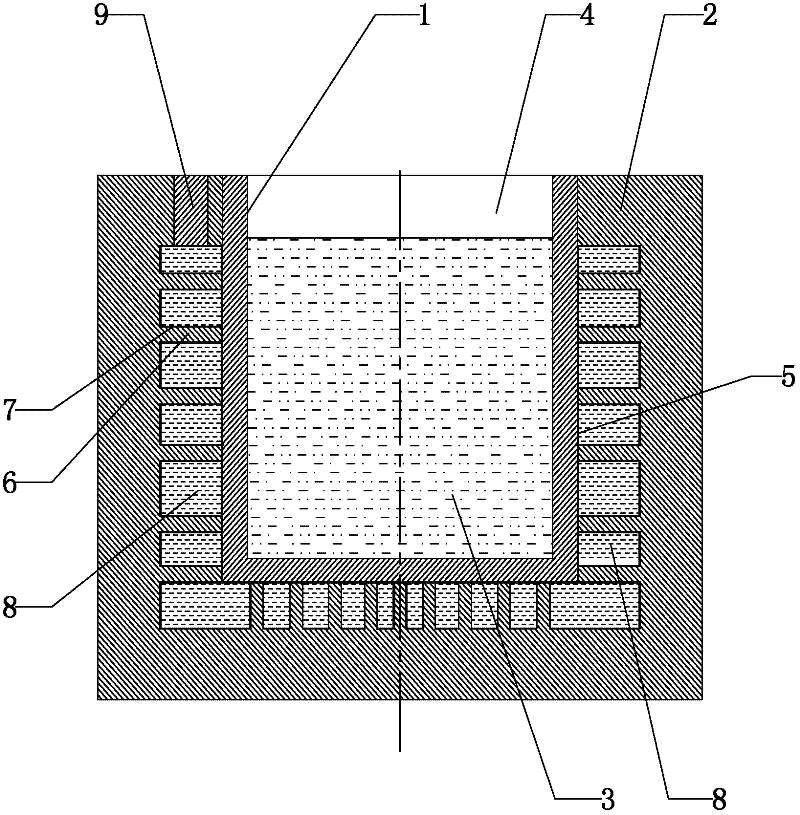

Self-temperature regulating mould and using method thereof

A mold and self-adjusting technology, which is applied in the direction of manufacturing tools, coatings, casting molding equipment, etc., can solve difficult problems such as pure metals, and achieve the effects of simple molds, convenient installation and operation, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In this embodiment, tin-bismuth alloy is used as the temperature-regulating metal to die-cast A356 aluminum alloy. Die-casting A356 aluminum alloy requires the material of mold body 1 to be H13 steel, the required minimum working temperature T1=130°C, and the maximum working temperature T2=225°C . Accordingly, the present invention selects the tin-bismuth alloy whose solidification temperature range is Ts=139° C. and TL=170° C. as the temperature-regulating metal. The method of use is: assemble the mold jacket 2 coated with heat-insulating paint 0.1mm thick and the mold body 1 coated with heat-conducting paint 0.1mm thick, and fix and seal firmly to form a temperature-adjusting chamber 8 with a volume 8 times the volume of the workpiece . After the selected temperature-regulating metal is melted and superheated to 10° C. (ie 180° C.) above the melting temperature, the temperature-regulating cavity 8 between the mold jacket 2 and the mold body 1 is filled and closed wit...

Embodiment 2

[0043] In this embodiment, bismuth metal is used as the temperature-regulating metal to carry out extrusion casting of 45 steel parts. The extrusion casting of 45 steel parts requires the material of mold body 1 to be 3Cr2W8V steel, the minimum working temperature T1=200°C, and the maximum working temperature T2=320°C . According to this, the present invention selects bismuth with a solidification temperature of 271° C. as the temperature-regulating metal. The method of use is as follows: the mold jacket 2 coated with a heat-insulating coating 0.1 mm thick and the mold body 1 coated with a heat-conducting coating 0.1 mm thick are assembled together and fixed. And seal firmly, form the temperature adjustment cavity 8 that can hold the volume of 4 times of workpiece quality. After the selected temperature-regulating metal is melted and superheated to 50° C. (ie 320° C.) above the melting temperature, the temperature-regulating cavity between the mold jacket 2 and the mold body 1...

Embodiment 3

[0045] In this embodiment, the temperature-regulating metal is eutectic tin-bismuth alloy, die-cast ZAMAK3 zinc alloy, and the mold body 1 is made of 3Cr5MoSiV hot work die steel. The minimum working temperature T1=120°C and the maximum working temperature T2=200°C are required. Accordingly, the present invention selects the eutectic tin-bismuth alloy whose solidification temperature is 139° C. as the temperature-regulating metal. The method of use is: assemble the mold jacket coated with heat-insulating paint 0.1mm thick and the mold body coated with heat-conducting paint 0.1mm thick, fix and seal firmly, and form a temperature-regulating cavity that can accommodate twice the mass of the workpiece. After the selected temperature-regulating metal is melted and superheated to 100° C. (ie 239° C.) above the melting temperature, the temperature-regulating cavity between the mold jacket 2 and the mold body 1 is filled and closed with a closing plug 9 . The temperature-adjusted met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| solidification point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com