Method for assembling silver nanoparticle film by using gas-liquid interface

A silver nanoparticle and liquid interface technology, which is applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve problems such as expensive reaction precursors, complicated experimental steps, and limited practical applications, and achieve good results. Raman enhancement effect, high detection sensitivity, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

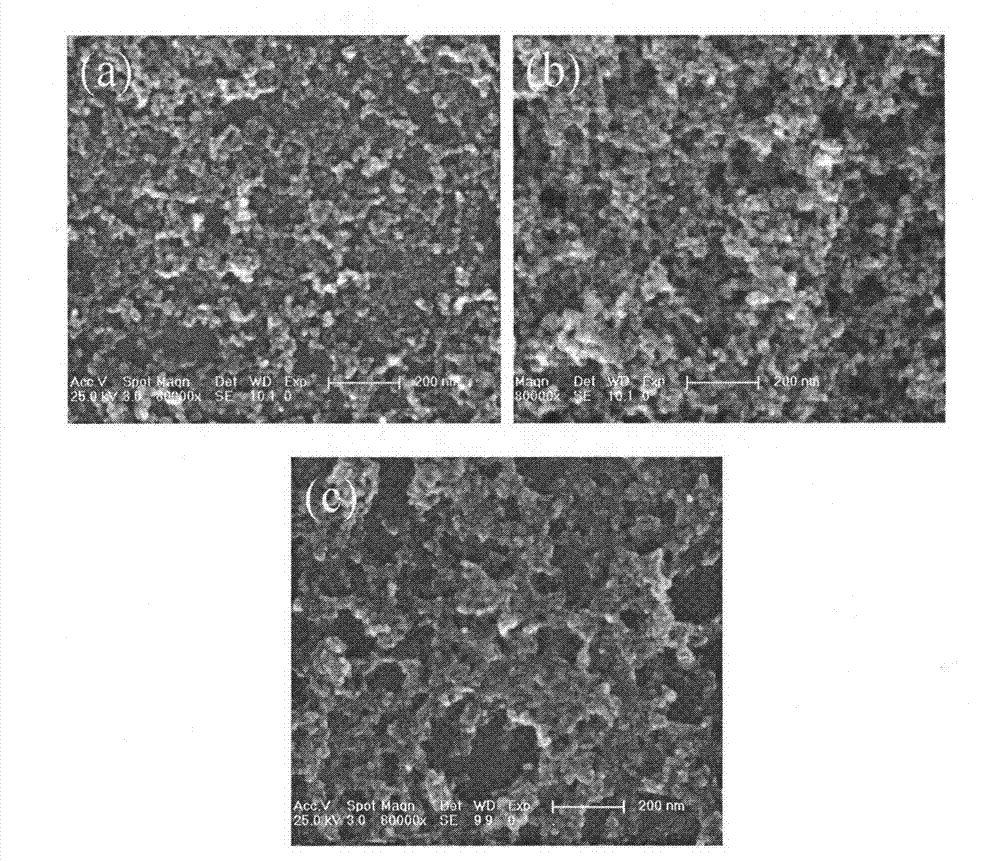

[0019] 1. Morphology of silver nanoparticle film

[0020] At room temperature, first use V 乙醇 :V 水 = 3:7 ratio of mixed solution to prepare 10 mmol L -1 Cinnamic acid solution, take 1.0 mL, 3.0 mL, 9.7 mL, 10 mmol L -1 Cinnamic acid solution was diluted to 9.7 mL with ultrapure water, and then 0.3 mL, 10 mmol·L -1 Mix the silver nitrate aqueous solution evenly. At this time, the molar ratios of cinnamic acid and silver nitrate are 10:3, 30:3, and 97:3 respectively. Under the condition of vigorous stirring, add the newly prepared 1% ( m / m) sodium borohydride aqueous solution until the color of the synthesized sol turns brown, at which point a film of silver nanoparticles appears on the air-solution interface. The silver nanoparticle film was collected with a 1.0 cm × 1.0 cm conductive glass and dried in the dark.

[0021] Such as figure 1 As shown in a, when the molar ratio of cinnamic acid and silver nitrate is 10:3, the prepared silver nanoparticle film is composed of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com