Dissolution technology of high alumina fly ash by method of sulphuric acid

A technology of high-alumina fly ash and sulfuric acid method, which is applied to the removal of alumina/hydroxide and solid waste, can solve the problems of iron and impurity removal, equipment corrosion, etc., and achieve corrosion and low cost , the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

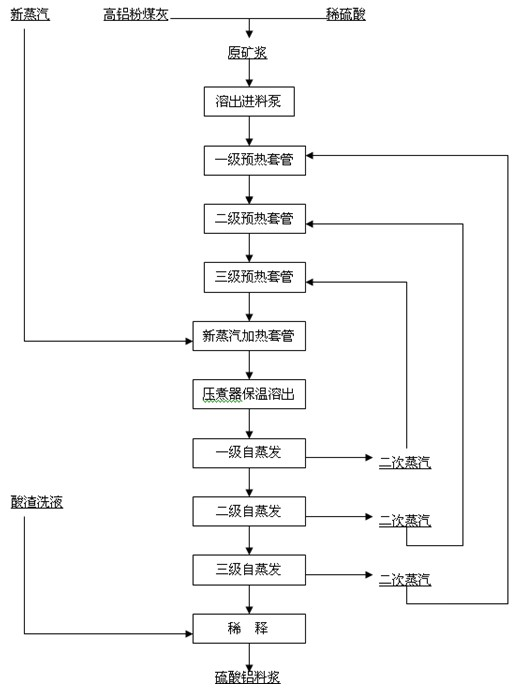

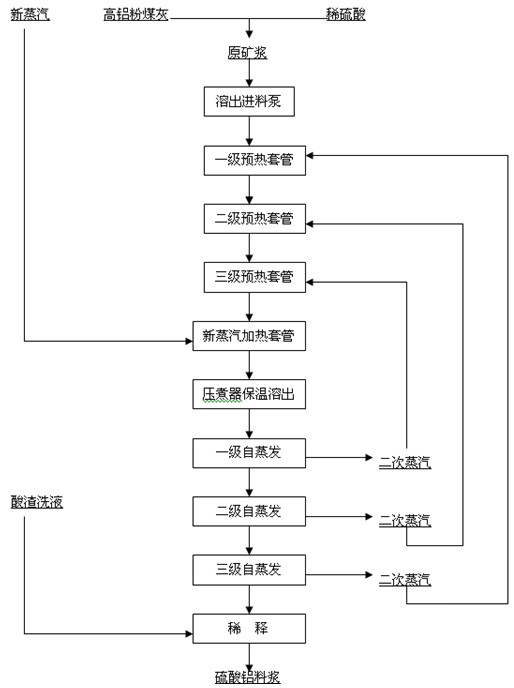

Image

Examples

Embodiment 1

[0019] Embodiment 1 of the present invention: high-alumina fly ash sulfuric acid dissolution process, the high-alumina fly ash with a mass percentage content of 45% and dilute sulfuric acid with a mass percentage concentration of 35% adopt the alumina dissolution chemical reaction theory The ratio of the calculated amount to 1.0 is mixed to make the raw ore pulp A; the raw ore pulp A is sent into the dissolution device (the dissolution device includes a casing, a pressure cooker and a self-evaporator) through a dissolution feed pump at room temperature, and firstly use The steam heats the 1-3 level casing to 88°C (the inner tube of the casing is a lead alloy inner tube, and the outer tube is a stainless steel tube), and the raw ore slurry A is preheated through the 1-3 level casing, and the preheated The temperature of the raw pulp A reaches 85-87°C to obtain the preheated pulp B; then re-introduce steam to heat the casing to 150°C, so that the preheated pulp B is heated to 150...

Embodiment 2

[0020] Embodiment 2 of the present invention: High-alumina fly ash sulfuric acid dissolution process, the high-alumina fly ash with a mass percentage content of 40% and dilute sulfuric acid with a mass percentage concentration of 38% adopt the alumina dissolution chemical reaction theory The ratio of the calculated amount to 1.0 is mixed to make the raw ore pulp A; the raw ore pulp A is sent into the dissolution device (the dissolution device includes a casing, a pressure cooker and a self-evaporator) through a dissolution feed pump at room temperature, and firstly use The steam heats the 1-3 casing to 90°C (the inner tube of the casing is a lead alloy inner tube, and the outer casing is a stainless steel tube), and the raw ore slurry A is preheated through the 1-3 casing, and the preheated The temperature of the raw ore pulp A reaches 87°C to obtain the preheated ore pulp B; then re-introduce steam to heat the casing to 150°C, so that the preheated ore pulp B is heated to 150°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com